Introduction: Navigating the Global Market for custom pvc raincoat

In the dynamic landscape of international trade, sourcing custom PVC raincoats poses unique challenges for B2B buyers. The need for durable, weather-resistant apparel is ever-present, especially in regions facing unpredictable climates such as Africa, South America, the Middle East, and Europe. Buyers often grapple with finding suppliers that not only meet quality standards but also offer competitive pricing and reliable delivery. This guide aims to demystify the complexities of sourcing custom PVC raincoats, providing valuable insights into various types, applications, and supplier vetting processes.

Throughout this comprehensive resource, we will explore the diverse range of custom PVC raincoats available in the market—from lightweight options suitable for warm climates to heavy-duty designs ideal for harsh weather conditions. Additionally, we will discuss the importance of understanding local regulations and market trends that influence purchasing decisions in different regions, including Nigeria and Germany.

By arming international B2B buyers with actionable strategies and critical knowledge, this guide empowers you to make informed decisions that enhance your procurement process. Whether you’re looking to invest in raincoats for industrial use, promotional merchandise, or retail distribution, our expert recommendations will streamline your sourcing efforts and help you secure the best value in the global marketplace.

التنقل بين المقالات

- Top 4 Custom Pvc Raincoat Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom pvc raincoat

- Understanding custom pvc raincoat Types and Variations

- Key Industrial Applications of custom pvc raincoat

- 3 Common User Pain Points for ‘custom pvc raincoat’ & Their Solutions

- Strategic Material Selection Guide for custom pvc raincoat

- In-depth Look: Manufacturing Processes and Quality Assurance for custom pvc raincoat

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom pvc raincoat’

- Comprehensive Cost and Pricing Analysis for custom pvc raincoat Sourcing

- Alternatives Analysis: Comparing custom pvc raincoat With Other Solutions

- Essential Technical Properties and Trade Terminology for custom pvc raincoat

- Navigating Market Dynamics and Sourcing Trends in the custom pvc raincoat Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom pvc raincoat

- تنويه هام وشروط الاستخدام

- Strategic Sourcing Conclusion and Outlook for custom pvc raincoat

Understanding custom pvc raincoat Types and Variations

| اسم النوع | السمات المميزة الرئيسية | تطبيقات B2B الأولية | موجز الإيجابيات والسلبيات للمشترين |

|---|---|---|---|

| معطف واق من المطر PVC شديد التحمل | Thick PVC material, reinforced seams, hoods | Industrial work, outdoor activities | الإيجابيات: Durable, excellent waterproofing. السلبيات: Heavier, may restrict movement. |

| معطف واق من المطر PVC خفيف الوزن | Thinner, flexible PVC, often packable | Casual use, events, promotional giveaways | الإيجابيات: Easy to carry, comfortable. السلبيات: Less durable, may not withstand extreme conditions. |

| Custom-Fit PVC Raincoat | Tailored sizing options, various colors/designs | Corporate branding, uniforms | الإيجابيات: Professional appearance, brand visibility. السلبيات: Higher cost, longer production time. |

| Multi-Purpose PVC Raincoat | Versatile design, can include additional features (e.g., pockets, ventilation) | Emergency services, outdoor recreation | الإيجابيات: Functional, adaptable to various needs. السلبيات: Complexity in design may increase costs. |

| Eco-Friendly PVC Raincoat | Made from recycled materials, sustainable production methods | Environmentally conscious brands | الإيجابيات: تناشد المستهلكين المهتمين بالبيئة. السلبيات: Availability may be limited, higher price point. |

What Are the Key Characteristics of Heavy-Duty PVC Raincoats?

Heavy-duty PVC raincoats are designed for rigorous use, featuring thick PVC material and reinforced seams that enhance durability. These raincoats often come with hoods and are ideal for industrial work environments, construction sites, and outdoor activities where protection from harsh weather is essential. When considering a purchase, B2B buyers should evaluate the specific needs of their workforce, ensuring that the weight and bulkiness of the coat align with the comfort and mobility requirements of their employees.

How Do Lightweight PVC Raincoats Compare for Casual Use?

Lightweight PVC raincoats are made from thinner, more flexible materials, making them easy to pack and carry. They are perfect for casual use during events or as promotional giveaways, appealing to a broader audience. B2B buyers should consider the trade-off between comfort and durability; while these raincoats are convenient, they may not withstand extreme weather conditions as effectively as their heavy-duty counterparts.

What Are the Benefits of Custom-Fit PVC Raincoats for Branding?

Custom-fit PVC raincoats offer tailored sizing options and can be produced in various colors and designs, making them ideal for corporate branding and uniforms. This personalization enhances brand visibility in outdoor settings. However, buyers must be prepared for potentially higher costs and longer production times. It’s crucial to balance the desire for a professional appearance with budget constraints and lead times.

Why Choose Multi-Purpose PVC Raincoats?

Multi-purpose PVC raincoats are designed with versatility in mind, often featuring additional elements like pockets and ventilation. These raincoats are suitable for emergency services and outdoor recreational activities, where adaptability is key. Buyers should assess the specific features that meet their operational needs, understanding that added complexity in design may result in higher production costs.

What Makes Eco-Friendly PVC Raincoats a Smart Choice?

Eco-friendly PVC raincoats are crafted from recycled materials and produced through sustainable methods, appealing to brands that prioritize environmental responsibility. While they resonate well with eco-conscious consumers, B2B buyers should be aware of potential limitations in availability and a higher price point. Companies should weigh the benefits of sustainability against budget considerations and the specific market they aim to serve.

Key Industrial Applications of custom pvc raincoat

| الصناعة/القطاع | Specific Application of custom pvc raincoat | القيمة/الفائدة للأعمال التجارية | اعتبارات التوريد الرئيسية لهذا التطبيق |

|---|---|---|---|

| الزراعة | Protective gear for farmers during heavy rain | يضمن سلامة العمال وإنتاجيتهم | Durability, comfort, and ease of movement are critical. |

| الإنشاءات | Rain protection for workers on-site | Minimizes downtime due to weather, enhancing project timelines | Customization options for branding and visibility. |

| تجهيز الأغذية | Hygiene and protection for workers in wet environments | Prevents contamination and maintains safety standards | Compliance with health regulations and material safety. |

| Logistics and Transportation | Rain gear for delivery personnel | Protects employees and goods, ensuring timely deliveries | Lightweight, waterproof materials for ease of use. |

| الاستجمام في الهواء الطلق | Gear for outdoor event staff during inclement weather | Enhances customer experience and staff comfort | Custom designs that reflect branding and event themes. |

How is Custom PVC Raincoat Used in Agriculture?

In the agriculture sector, custom PVC raincoats are vital for protecting farmers and agricultural workers during heavy rainfall. These raincoats are designed to be durable and waterproof, ensuring that workers can continue their tasks without the risk of getting soaked, which can lead to health issues and decreased productivity. Buyers in this sector should prioritize comfort and flexibility in the design to allow for ease of movement while working in the fields. Additionally, sourcing considerations may include the ability to customize raincoats with company branding, which can enhance visibility and promote the business.

What Role Does Custom PVC Raincoat Play in Construction?

In construction, custom PVC raincoats serve as essential protective gear for workers exposed to the elements on job sites. Raincoats help mitigate the risks of slips and falls due to wet surfaces, minimizing project delays caused by adverse weather conditions. For international buyers, especially in regions prone to heavy rains, sourcing raincoats that meet specific safety standards is crucial. Customization options that allow for high-visibility colors can also enhance worker safety on-site, making them easier to spot in low-light or stormy conditions.

How is Custom PVC Raincoat Beneficial in Food Processing?

The food processing industry requires stringent hygiene standards, and custom PVC raincoats are an effective solution for protecting workers in wet environments. These raincoats help prevent contamination of food products while ensuring that employees remain dry and comfortable. When sourcing for this sector, buyers must consider materials that comply with health regulations, including resistance to chemicals and easy cleanability. Customization can also include features like pockets for tools or equipment, which can enhance operational efficiency.

Why is Custom PVC Raincoat Important for Logistics and Transportation?

In logistics and transportation, custom PVC raincoats protect delivery personnel from rain while ensuring that goods are not compromised during transit. By providing effective rain protection, businesses can maintain their delivery schedules and enhance customer satisfaction. Buyers in this sector should look for lightweight materials that do not hinder mobility, as well as options for branding that can serve as a marketing tool during deliveries. Ensuring that the raincoat is waterproof and durable is essential for long-term use in various weather conditions.

How Does Custom PVC Raincoat Enhance Outdoor Recreation Events?

For outdoor recreation events, custom PVC raincoats are crucial for staff working in unpredictable weather conditions. These raincoats help maintain a positive experience for attendees by ensuring that event staff remain dry and comfortable, which can lead to improved service delivery. When sourcing raincoats for this application, B2B buyers should consider customization options that align with the event’s branding and themes. Additionally, features like breathable fabrics can enhance comfort for staff who may be active throughout the event.

3 Common User Pain Points for ‘custom pvc raincoat’ & Their Solutions

Scenario 1: Sizing and Fit Issues with Custom PVC Raincoats

المشكلة One common challenge B2B buyers face is ensuring the correct sizing and fit of custom PVC raincoats for their workforce. In industries such as agriculture, construction, and logistics, where rain exposure is frequent, ill-fitting raincoats can lead to employee discomfort, safety risks, and decreased productivity. Buyers may struggle with balancing the need for a snug fit that allows for movement while ensuring adequate coverage and protection from the elements. Furthermore, standard sizing may not cater to all body types, leading to dissatisfaction among employees who feel uncomfortable in their gear.

الحل: To address sizing issues effectively, B2B buyers should engage in a comprehensive measurement process before placing orders. This involves collecting accurate body measurements from employees and providing these dimensions to manufacturers. Buyers can also request sample sizes to distribute among employees for fitting before finalizing bulk orders. Additionally, consider manufacturers who offer a range of customizable options, including adjustable features like straps or elastic bands that can cater to different body types. This proactive approach can significantly improve employee satisfaction and ensure the raincoats are practical for everyday use.

Scenario 2: Durability Concerns in Harsh Environments

المشكلة Durability is a critical concern for B2B buyers sourcing custom PVC raincoats, especially in regions with extreme weather conditions. Buyers may experience frustration when raincoats fail to withstand harsh environmental factors such as intense UV rays, heavy rainfall, or abrasive materials. In sectors like mining or outdoor maintenance, where raincoats are subjected to rigorous use, frequent replacements can result in increased costs and operational downtime.

الحل: To ensure the durability of custom PVC raincoats, buyers should prioritize sourcing materials specifically designed for harsh conditions. Look for suppliers who use high-quality, reinforced PVC that offers UV resistance and can endure exposure to chemicals or heavy wear. Request detailed specifications on the material’s thickness and any treatment processes that enhance longevity. Furthermore, consider conducting field tests with sample products in real working conditions before committing to a large order. This approach helps to ascertain the true performance of the raincoats in the intended environment, ensuring long-term value and reliability.

Scenario 3: Limited Customization Options Leading to Brand Inconsistency

المشكلة B2B buyers often encounter challenges with the limited customization options available for custom PVC raincoats. In industries where brand identity is crucial, such as hospitality or event management, having a uniform look is essential. Buyers may find that some manufacturers offer only basic color choices or generic designs, leading to inconsistency in branding and a lack of professional appearance among employees.

الحل: To overcome this challenge, buyers should seek out suppliers that provide extensive customization options, including a variety of colors, logos, and design elements. Discuss your branding requirements in detail with potential manufacturers and request examples of previous custom projects to evaluate their capabilities. Additionally, consider suppliers who use advanced printing techniques for logo application, ensuring high-quality, durable branding that can withstand wear and tear. Establishing a strong partnership with a manufacturer that understands the importance of brand consistency will not only enhance your company’s image but also promote employee pride in their uniforms.

Strategic Material Selection Guide for custom pvc raincoat

When selecting materials for custom PVC raincoats, it is essential to consider various factors that impact performance, durability, and compliance with international standards. Here, we analyze four common materials used in the production of custom PVC raincoats, focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

ما هي الخصائص الرئيسية للبلاستيك PVC في صناعة معاطف المطر؟

كلوريد البوليفينيل المتعدد الفينيل (PVC) is a widely used plastic known for its excellent waterproofing properties. It has a temperature tolerance of approximately -10°C to 60°C, making it suitable for various climates. PVC is also resistant to many chemicals, which enhances its durability in harsh environments.

الإيجابيات: PVC raincoats are generally cost-effective and offer good resistance to wear and tear. They can be produced in various colors and thicknesses, allowing for customization.

السلبيات: However, PVC can become brittle over time, especially when exposed to UV light, which may limit its lifespan. Additionally, its production process can involve harmful chemicals, raising environmental concerns.

How Does EVA Compare as an Alternative Material for Raincoats?

Ethylene Vinyl Acetate (EVA) is another material that offers flexibility and durability. With a temperature range of -30°C to 70°C, EVA is suitable for diverse weather conditions. It is also known for its resistance to UV light and low-temperature flexibility.

الإيجابيات: EVA raincoats are lightweight and provide excellent comfort, making them ideal for prolonged wear. They are also less prone to cracking compared to PVC.

السلبيات: On the downside, EVA can be more expensive than PVC, which may impact budget constraints for some buyers. Additionally, its chemical resistance is not as robust as that of PVC.

What Role Does PU Play in Custom Raincoat Applications?

Polyurethane (PU) is another popular choice for raincoat manufacturing, known for its high elasticity and durability. PU can withstand temperatures from -20°C to 80°C, making it versatile for various climates.

الإيجابيات: PU raincoats are highly breathable, which enhances comfort during wear. They also offer superior resistance to abrasion and punctures, making them suitable for rugged outdoor activities.

السلبيات: However, PU can be more costly than both PVC and EVA, which may deter some buyers. Its production process also requires careful handling to avoid environmental issues.

What are the Unique Benefits of Nylon in Raincoat Production?

نايلون is a synthetic fabric that is often coated with PVC or PU to enhance its waterproof capabilities. It has a temperature tolerance of -40°C to 100°C, making it highly versatile.

الإيجابيات: Nylon raincoats are lightweight and offer excellent durability. They are also resistant to mildew and mold, which is beneficial in humid climates.

السلبيات: The primary drawback is that nylon alone is not waterproof unless treated with a coating, which adds to production complexity and cost.

What Should International B2B Buyers Consider When Choosing Materials?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider compliance with local standards such as ASTM, DIN, or JIS. Additionally, environmental regulations are becoming increasingly stringent, and choosing materials with lower ecological footprints can enhance marketability. Preferences for materials may also vary by region; for instance, buyers in Germany may prioritize durability and sustainability, while those in Nigeria may focus on cost-effectiveness and availability.

| المواد | Typical Use Case for custom pvc raincoat | الميزة الرئيسية | العيب/التقييد الرئيسي | التكلفة النسبية (منخفضة/متوسطة/مرتفعة) |

|---|---|---|---|---|

| بولي كلوريد الفينيل | General-purpose rainwear for various climates | Cost-effective and customizable | Can become brittle over time | منخفضة |

| إيفا | Lightweight rainwear for outdoor activities | Excellent comfort and flexibility | Higher cost than PVC | ميد |

| البولي يوريثان | High-performance rainwear for extreme conditions | Superior durability and breathability | More expensive than PVC and EVA | عالية |

| نايلون | Lightweight and breathable rainwear | Resistant to mildew and mold | Requires coating for waterproofing | ميد |

This strategic material selection guide aims to equip B2B buyers with the necessary insights to make informed decisions when sourcing custom PVC raincoats, ensuring they meet both performance and compliance requirements in their respective markets.

In-depth Look: Manufacturing Processes and Quality Assurance for custom pvc raincoat

What Are the Main Stages in the Manufacturing Process of Custom PVC Raincoats?

The manufacturing process for custom PVC raincoats involves several critical stages that ensure the product meets the required specifications and quality standards. The main stages include material preparation, forming, assembly, and finishing.

-

إعداد المواد: The process begins with sourcing high-quality PVC material. This involves selecting the right thickness and type of PVC, ensuring it meets the durability and flexibility requirements for raincoats. Suppliers often provide samples, which can be tested for quality and performance. The raw materials are then cut into the required sizes based on the design specifications.

-

التشكيل: In this stage, the cut PVC sheets are subjected to heat and pressure to form the desired shape. Techniques such as thermoforming are commonly used, where the material is heated until pliable and then molded into the specific design of the raincoat. Precision is crucial here, as any inaccuracies can affect the fit and functionality of the final product.

-

التجميع: Once the components are formed, they are assembled to create the complete raincoat. This may involve welding, sewing, or using adhesives to join different parts together. Each method has its advantages; for instance, welding can offer a waterproof seal, while sewing may provide additional flexibility. Careful attention is paid to seams and closures to ensure they are secure and effective against water ingress.

-

التشطيب: The final stage includes adding features such as hoods, pockets, and reflective strips. Quality checks are performed to ensure that all components are correctly attached and that the raincoat meets the specified design. The finishing process also involves inspecting the overall aesthetics, ensuring that the final product is visually appealing and functional.

What Key Techniques Are Used in the Production of Custom PVC Raincoats?

Various techniques are employed during the manufacturing process to ensure the quality and performance of custom PVC raincoats. Some of the most significant techniques include:

-

Heat Sealing: This technique uses heat to bond PVC materials together, creating waterproof seams. It is particularly beneficial for raincoats, where maintaining water resistance is critical.

-

Sewing with Waterproof Threads: For designs that incorporate seams, using specialized waterproof threads can prevent water from penetrating through stitch holes, enhancing the raincoat’s durability.

-

Digital Printing: Custom designs and logos can be printed directly onto the PVC material using advanced digital printing techniques, allowing for high-quality, vibrant graphics that withstand the elements.

-

Quality Control Techniques: Automated inspection systems can be employed during various stages of production to ensure that products meet quality specifications. This includes checking dimensions, seam strength, and overall finish.

How Is Quality Assurance Managed for Custom PVC Raincoats?

Quality assurance (QA) is an essential aspect of the manufacturing process for custom PVC raincoats, ensuring that products meet international standards and client expectations. Here are some key elements of the QA process:

-

الامتثال للمعايير الدولية: Many manufacturers adhere to international quality standards such as ISO 9001, which outlines the criteria for a quality management system. Compliance with these standards ensures that manufacturing processes are efficient and that products consistently meet customer and regulatory requirements.

-

الشهادات الخاصة بالصناعة: Depending on the target market, additional certifications may be necessary. For example, CE marking for products sold in Europe indicates compliance with health, safety, and environmental protection standards.

-

نقاط التحقق من الجودة: Effective quality control involves several checkpoints throughout the manufacturing process:

– مراقبة الجودة الواردة (IQC): Raw materials are inspected upon arrival to ensure they meet specified requirements.

– مراقبة الجودة أثناء المعالجة (IPQC): Ongoing checks during production help identify any defects or issues early in the process, allowing for corrective actions.

– مراقبة الجودة النهائية (FQC): The completed raincoats undergo a final inspection to ensure they meet all specifications and quality standards before shipment. -

طرق الاختبار الشائعة: Various testing methods are used to assess the quality of custom PVC raincoats, including:

– Water Resistance Tests: To verify that the raincoat can withstand specific water pressure levels.

– Tensile Strength Tests: To ensure that the material can endure stress and strain without tearing.

– Colorfastness Tests: To check that colors remain vibrant and do not fade when exposed to sunlight or water.

كيف يمكن للمشترين بين الشركات التحقق من عمليات مراقبة جودة الموردين؟

For international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are effective strategies to ensure quality assurance:

-

إجراء عمليات تدقيق الموردين: Regular audits can provide insights into a supplier’s manufacturing processes, quality control measures, and compliance with international standards. Buyers should request access to audit reports or offer to conduct their own audits.

-

Request Documentation: Suppliers should provide documentation related to their quality management systems, including ISO certifications, test results, and inspection reports. This transparency helps buyers assess the reliability and quality of the manufacturing processes.

-

Engage Third-Party Inspection Services: Utilizing third-party inspection services can offer an unbiased evaluation of the supplier’s quality control practices. These services can perform inspections at various stages of production, providing detailed reports on quality compliance.

-

Understand Regional Regulations: Buyers should familiarize themselves with specific regulations and quality assurance requirements in their region. For instance, European buyers may need to ensure that products meet CE marking requirements, while buyers in Africa may need to consider local standards for materials and safety.

ما هي الفروق الدقيقة في مراقبة الجودة بالنسبة للمشترين الدوليين بين الشركات؟

When dealing with international suppliers, B2B buyers must navigate various quality control nuances:

-

الاختلافات الثقافية: Different countries may have varying approaches to quality assurance and manufacturing practices. Understanding these cultural differences can help in establishing effective communication and expectations.

-

Logistical Challenges: International shipping may introduce risks such as damage during transit. Buyers should discuss packaging and shipping methods with suppliers to ensure that products arrive in optimal condition.

-

الامتثال التنظيمي: Each market may have distinct regulatory requirements that can affect product quality. Buyers must ensure that their suppliers are knowledgeable about these regulations and can provide compliant products.

By understanding the manufacturing processes and quality assurance measures involved in custom PVC raincoats, B2B buyers can make informed decisions and select reliable suppliers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom pvc raincoat’

مقدمة

Sourcing custom PVC raincoats requires a strategic approach to ensure that the final product meets your quality standards and business needs. This checklist serves as a practical guide for B2B buyers looking to procure high-quality raincoats tailored to specific requirements. By following these steps, you can streamline the procurement process, minimize risks, and ensure a successful partnership with suppliers.

الخطوة 1: تحديد المواصفات الفنية الخاصة بك

Clearly outline the specifications for the custom PVC raincoats you need. Consider factors such as material thickness, waterproof ratings, design features (e.g., hoods, pockets), and sizes. This step is critical as it sets the foundation for your sourcing decisions and helps suppliers understand your precise requirements.

- جودة المواد: Specify the type of PVC to ensure durability and resistance to harsh weather conditions.

- Design Features: Include any custom branding or color preferences to align the product with your company’s identity.

الخطوة 2: البحث عن الموردين المحتملين

Conduct thorough research to identify potential suppliers who specialize in custom PVC raincoats. Use online directories, trade shows, and industry networks to compile a list of candidates. This initial step is vital for ensuring that you have a pool of qualified suppliers to evaluate.

- سمعة المورد: Check online reviews and testimonials to gauge reliability and product quality.

- Industry Experience: Look for suppliers with a proven track record in your specific sector to ensure they understand your needs.

الخطوة 3: تقييم شهادات الموردين

Before proceeding, verify that potential suppliers possess the necessary certifications and quality standards relevant to your industry. This verification is crucial for ensuring compliance with safety regulations and quality benchmarks.

- Quality Certifications: Request documentation for ISO, CE, or other relevant standards that indicate a commitment to quality.

- ممارسات الاستدامة: If important to your brand, inquire about environmentally friendly practices in their manufacturing processes.

الخطوة 4: طلب عينات

Ask for samples of the custom PVC raincoats to assess their quality firsthand. Evaluating samples allows you to check the material, construction, and overall craftsmanship, helping you make an informed decision before placing a bulk order.

- Testing Durability: Conduct water resistance tests and wear tests to ensure the product meets your expectations.

- الملاءمة والراحة: Ensure the samples provide a comfortable fit, as this is essential for user satisfaction.

الخطوة 5: التفاوض على الأسعار والشروط

Once you’ve identified a suitable supplier, engage in negotiations to finalize pricing, payment terms, and delivery schedules. This step is essential to establish a mutually beneficial agreement that meets your budget while ensuring supplier commitment.

- خصومات بالجملة: Inquire about pricing tiers based on order volume to optimize your purchasing costs.

- Delivery Timeline: Discuss lead times to align with your inventory needs and avoid stockouts.

الخطوة 6: Establish Clear Communication Channels

Set up effective communication channels with your chosen supplier. Clear communication is key to addressing any issues that may arise during production and ensuring that both parties are aligned on expectations.

- Regular Updates: Schedule periodic check-ins to monitor production progress and address any concerns promptly.

- آلية التغذية الراجعة: Implement a feedback loop to share insights on product performance and areas for improvement.

الخطوة 7: Conduct Quality Assurance Checks

Before final delivery, conduct quality assurance checks to ensure the products meet your specifications and standards. This final step is crucial for maintaining quality control and ensuring customer satisfaction.

- On-site Inspections: If feasible, visit the manufacturing facility to perform checks or hire third-party inspection services.

- Final Product Testing: Ensure that the finished raincoats meet all agreed-upon specifications and quality benchmarks before accepting the shipment.

By following this checklist, B2B buyers can navigate the complexities of sourcing custom PVC raincoats more effectively, ensuring they partner with reliable suppliers who deliver high-quality products tailored to their needs.

Comprehensive Cost and Pricing Analysis for custom pvc raincoat Sourcing

What Are the Key Cost Components in Custom PVC Raincoat Production?

When sourcing custom PVC raincoats, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

المواد: The quality and type of PVC used directly influence the cost. Higher-grade materials may incur a premium but offer better durability and performance, which can be crucial for certain markets, especially in harsher climates.

-

العمالة: Labor costs can vary significantly depending on the manufacturing location. Countries with lower labor costs may offer more competitive pricing, but this can also affect quality. Buyers should consider the balance between cost and craftsmanship.

-

نفقات التصنيع الزائدة: This includes expenses related to facility maintenance, utilities, and administrative costs. Efficient manufacturing processes can help reduce these overheads, impacting the final price.

-

الأدوات: Customization often requires specialized tools or molds, which can add to upfront costs. Buyers should inquire about tooling fees and how these are amortized over production runs.

-

مراقبة الجودة: Ensuring that products meet specific standards can incur additional QC costs. Investing in stringent quality checks can reduce returns and dissatisfaction, ultimately saving costs in the long term.

-

الخدمات اللوجستية: Shipping and handling costs can vary based on the destination and shipping terms. Understanding Incoterms is essential for clarifying who bears the cost of transportation, insurance, and tariffs.

-

الهامش: Suppliers will typically add a markup to cover their operating expenses and profit. This margin can fluctuate based on market demand and competition.

How Do Price Influencers Affect Custom PVC Raincoat Sourcing?

Several factors influence the pricing of custom PVC raincoats, particularly for international buyers.

-

الحجم/معدل العرض/الطلب: Minimum order quantities (MOQs) can significantly affect pricing. Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs to negotiate favorable terms.

-

المواصفات والتخصيص: Unique designs or features can increase costs. Customization not only affects material and labor but also tooling and QC processes. Clear communication of requirements can prevent unexpected expenses.

-

جودة المواد والشهادات: Certifications (e.g., ISO, CE) may be necessary for certain markets and can add to costs. However, they can also enhance the product’s marketability and compliance.

-

عوامل الموردين: The reputation and reliability of the supplier play a crucial role. Established suppliers may charge more but offer better quality assurance and service. Conducting due diligence can mitigate risks.

-

المصطلحات التجارية الدولية: Understanding the implications of Incoterms is vital for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate responsibility for shipping costs and risks, influencing overall pricing.

What Are Essential Buyer Tips for Negotiating Custom PVC Raincoat Prices?

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation and cost management strategies are essential.

-

تفاوض بحكمة: Engage in transparent discussions with suppliers about pricing structures and potential discounts for larger orders. Establishing a good relationship can lead to better terms.

-

التركيز على كفاءة التكلفة: Look beyond the initial price and consider the Total Cost of Ownership (TCO), which includes maintenance, durability, and potential return rates. Investing slightly more upfront can result in long-term savings.

-

كن على دراية بالفروق الدقيقة في التسعير: International buyers should be aware of currency fluctuations, tariffs, and import duties that may affect the final cost. Understanding local market conditions can also provide leverage in negotiations.

-

Request Detailed Quotes: Always ask for detailed quotations that break down costs. This transparency can reveal areas where costs can be reduced or where adjustments can be made.

إخلاء المسؤولية عن الأسعار الاسترشادية

Prices for custom PVC raincoats can vary widely based on the factors discussed above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing and quality.

Alternatives Analysis: Comparing custom pvc raincoat With Other Solutions

When evaluating options for protective outerwear, particularly in industrial and outdoor settings, it is essential to consider various alternatives to custom PVC raincoats. Each alternative presents unique benefits and challenges that may align differently with a buyer’s specific operational needs. Below, we compare custom PVC raincoats against two viable alternatives: polyurethane rain gear and traditional fabric-based rain jackets.

| جانب المقارنة | Custom PVC Raincoat | Polyurethane Rain Gear | Traditional Fabric-Based Rain Jacket |

|---|---|---|---|

| الأداء | High waterproofing; durable; resistant to chemicals | Excellent waterproofing; flexible; lightweight | Moderate waterproofing; breathability varies |

| التكلفة | Generally higher initial investment | Competitive pricing; varies by brand | Typically lower cost; budget-friendly options available |

| سهولة التنفيذ | Easy to wear; available in custom sizes | Lightweight and easy to put on; some require layering | Simple to use; fits under other clothing |

| الصيانة | Requires regular cleaning to maintain appearance | Easy to clean; resistant to stains | Machine washable; may require special care |

| أفضل حالة استخدام | Heavy-duty industrial applications; wet environments | Versatile for outdoor activities; moderate exposure | Casual wear; light rain; urban settings |

What are the Advantages and Disadvantages of Polyurethane Rain Gear Compared to Custom PVC Raincoats?

Polyurethane rain gear is a popular alternative due to its lightweight nature and flexibility, making it comfortable for prolonged use. It offers excellent waterproofing and can be more breathable than PVC, which helps in reducing sweat buildup. However, polyurethane may not be as chemically resistant as PVC, making it less suitable for certain industrial environments where exposure to harsh substances is common. Additionally, while it can be competitively priced, high-quality options may still reach similar price points as PVC raincoats.

How Do Traditional Fabric-Based Rain Jackets Compare to Custom PVC Raincoats?

Traditional fabric-based rain jackets provide a more casual option, often made from breathable materials that can handle light to moderate rain. They are generally more affordable and easy to maintain, as they can typically be machine washed. However, their waterproofing capabilities might not match those of custom PVC raincoats, especially in heavy downpours. Fabric jackets may also lack durability in rugged conditions, making them less ideal for industrial applications where heavy-duty protection is necessary.

Conclusion: How Should B2B Buyers Decide on the Right Raincoat Solution?

Choosing the right raincoat solution involves assessing the specific needs of your operation. Custom PVC raincoats excel in high-stakes environments where chemical resistance and durability are paramount. In contrast, polyurethane rain gear offers a balance of flexibility and performance for versatile outdoor use. Traditional fabric-based jackets are suitable for lighter applications and budget-conscious buyers. Ultimately, the decision should be driven by the operational context, budget constraints, and the level of protection required, ensuring that the chosen solution aligns with the buyer’s functional and financial objectives.

Essential Technical Properties and Trade Terminology for custom pvc raincoat

What Are the Key Technical Properties of Custom PVC Raincoats?

When considering custom PVC raincoats, various technical properties play a crucial role in ensuring the product meets the specific needs of businesses. Here are several critical specifications to understand:

-

درجة المادة: The grade of PVC used in raincoat manufacturing is vital for durability and performance. Higher-grade PVC offers better resistance to wear, tear, and environmental factors, making it suitable for heavy-duty applications. For B2B buyers, selecting the right material grade ensures the raincoat can withstand harsh conditions, which is especially important in industries like agriculture and construction.

-

مقاومة الماء: This property measures the ability of the raincoat to repel water. A raincoat with high water resistance keeps the wearer dry and comfortable, essential for outdoor activities. For international buyers, understanding the water resistance rating (often expressed in millimeters) helps in evaluating whether the product meets local climate challenges.

-

قابلية التنفس: While water resistance is crucial, breathability ensures comfort by allowing moisture from sweat to escape. This is particularly significant in warmer climates, where heat retention can lead to discomfort. Buyers should look for specifications that indicate breathability levels, as this affects the overall usability of the raincoat.

-

Tensile Strength: This property refers to the resistance of the material to being pulled apart. It is measured in units like Newtons and is a critical factor for durability. In B2B contexts, products with higher tensile strength are less likely to tear during use, reducing replacement costs and enhancing user satisfaction.

-

الوزن: The weight of the raincoat affects portability and ease of use. Lighter materials are more suitable for activities requiring mobility, while heavier materials may offer better protection. Buyers should assess the weight specifications to align with the intended use of the raincoat, ensuring it meets their operational needs.

-

مستويات التحمل: Tolerance refers to the allowable deviation from specified dimensions. In manufacturing, maintaining tight tolerances is essential for ensuring quality and fit. Buyers should inquire about tolerance levels to ensure that the raincoats will fit as intended, especially when ordering in bulk.

What Are Common Trade Terminologies Related to Custom PVC Raincoats?

Understanding industry jargon is critical for effective communication and negotiation in the B2B sector. Here are some common terms you should know:

-

OEM (الشركة المصنعة للمعدات الأصلية): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. When sourcing custom PVC raincoats, knowing whether a supplier operates as an OEM can help buyers understand the level of customization and branding options available.

-

موك (الحد الأدنى لكمية الطلب): This is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is essential for buyers to ensure that their order aligns with budget constraints and storage capabilities, particularly for international shipments.

-

طلب عرض الأسعار (RFQ): An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific quantities of products. This is a critical step in the procurement process, allowing businesses to compare options and negotiate better terms.

-

إنكوترمز (الشروط التجارية الدولية): These are standardized terms used in international trade to define responsibilities for shipping, insurance, and tariffs between buyers and sellers. Familiarity with Incoterms helps buyers understand their obligations and manage risks associated with international shipments of custom PVC raincoats.

-

المهلة الزمنية: This term refers to the amount of time it takes from placing an order until it is delivered. For B2B buyers, understanding lead times is crucial for planning and inventory management, particularly in regions with unpredictable weather patterns.

-

خيارات التخصيص: This refers to the various ways a product can be tailored to meet specific requirements, such as colors, sizes, and additional features. Buyers should inquire about customization options to ensure that the raincoats align with their branding and functional needs.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing custom PVC raincoats, ultimately leading to better product satisfaction and business outcomes.

Navigating Market Dynamics and Sourcing Trends in the custom pvc raincoat Sector

What are the Key Market Dynamics and Trends Affecting Custom PVC Raincoat Sourcing?

The custom PVC raincoat market is shaped by a variety of global drivers that are influencing B2B sourcing strategies. Key trends include the increasing demand for durable, waterproof apparel in sectors such as agriculture, construction, and outdoor recreation. As climate change leads to unpredictable weather patterns, businesses are prioritizing high-quality protective gear, thus driving the need for custom solutions that cater to specific industry requirements.

Emerging technologies are also transforming how businesses source custom PVC raincoats. Innovations such as digital printing and on-demand manufacturing allow suppliers to offer personalized designs with shorter lead times, appealing to international buyers. Additionally, the rise of e-commerce platforms facilitates global reach, enabling B2B buyers from regions like Africa and South America to access suppliers in Europe and Asia more efficiently.

The market dynamics are further influenced by economic factors, including fluctuating raw material prices and trade tariffs. Buyers must stay informed about these variables to navigate potential cost increases. Understanding regional preferences is crucial, as cultural differences can dictate design choices, color preferences, and functionality, particularly in diverse markets like Nigeria and Germany.

How Can Sustainability and Ethical Sourcing Impact B2B Purchases of Custom PVC Raincoats?

Sustainability is becoming a pivotal factor in the sourcing of custom PVC raincoats, as businesses face increasing pressure to adopt environmentally responsible practices. The production of PVC has been scrutinized for its environmental impact, leading buyers to seek alternatives that minimize ecological harm. This includes sourcing from suppliers that utilize recycled materials or adopt eco-friendly manufacturing processes.

Ethical supply chains are equally important for B2B buyers. Transparency in sourcing can enhance a brand’s reputation and build trust with customers. Buyers should prioritize suppliers that are certified with ‘green’ credentials, such as ISO 14001 or OEKO-TEX certifications, which signify adherence to environmental and safety standards. By partnering with ethical manufacturers, companies can not only improve their sustainability profile but also align with the values of their target markets, particularly in regions like Europe where consumer demand for sustainable products is high.

What is the Historical Context of Custom PVC Raincoats in the B2B Market?

The evolution of custom PVC raincoats can be traced back to the mid-20th century when advancements in synthetic materials began to revolutionize protective clothing. Initially designed for industrial and military applications, PVC raincoats gained popularity due to their durability and waterproof properties. Over the years, as outdoor leisure activities expanded, the demand for stylish yet functional rainwear surged.

In the B2B context, the historical significance lies in the transition from generic, one-size-fits-all solutions to custom-designed products tailored to specific business needs. This shift has enabled companies to enhance brand identity through personalized designs while ensuring that their workforce is adequately protected from the elements. Today, the market continues to evolve, driven by technological advancements and changing consumer expectations, making it imperative for international buyers to remain adaptable and forward-thinking in their sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of custom pvc raincoat

-

How do I ensure the quality of custom PVC raincoats before purchasing?

To ensure the quality of custom PVC raincoats, request samples from potential suppliers. Evaluate the material for durability, waterproofing, and comfort. Additionally, consider suppliers with ISO certifications or other quality assurance standards. Implementing a quality control process during production, such as on-site inspections or third-party audits, can further mitigate risks. Establish clear specifications regarding material thickness, stitching quality, and design features to hold suppliers accountable. -

What is the best way to customize PVC raincoats for my brand?

To effectively customize PVC raincoats, collaborate closely with your supplier to discuss design options, including colors, logos, and additional features like reflective strips or pockets. Provide your brand guidelines to ensure consistency. Utilize digital mockups to visualize designs before production. It’s also beneficial to consider the target market’s preferences, ensuring the customization resonates well with your audience. Request a small batch for initial feedback before committing to larger orders. -

What are typical minimum order quantities (MOQs) for custom PVC raincoats?

Minimum order quantities for custom PVC raincoats vary by supplier and can range from 100 to several thousand units. Factors influencing MOQs include the complexity of customization, production capabilities, and material costs. When negotiating with suppliers, inquire if they can accommodate lower MOQs, especially for new clients or trial orders. This flexibility can be crucial for businesses testing new markets or product lines. -

What payment terms are standard when sourcing custom PVC raincoats internationally?

Standard payment terms for international orders often include a deposit (usually 30-50%) before production and the balance upon completion or prior to shipping. Some suppliers may offer letters of credit or escrow services for added security. It’s essential to clarify payment methods accepted (e.g., bank transfers, credit cards) and any associated fees. Always ensure that the terms are documented in the purchase agreement to avoid misunderstandings. -

How can I vet suppliers of custom PVC raincoats effectively?

To vet suppliers, start by checking their business credentials, including registration and certifications. Look for reviews and testimonials from previous clients. Request references and follow up on their experiences. Evaluate their production capabilities by visiting their facilities if possible or through virtual tours. It’s also beneficial to assess their communication responsiveness and willingness to accommodate your specific needs. -

ما هي الاعتبارات اللوجستية التي يجب أن أضعها في الحسبان عند استيراد معاطف المطر البلاستيكية؟

When importing PVC raincoats, consider shipping methods (air vs. sea), lead times, and customs regulations specific to your country. Calculate total landed costs, including shipping, duties, and taxes, to avoid unexpected expenses. Collaborating with a freight forwarder can streamline the process, ensuring compliance with local laws and efficient delivery. It’s also advisable to have a contingency plan for delays or customs issues. -

Are there specific certifications or regulations for PVC raincoats in international markets?

Yes, different countries may have specific regulations regarding the materials used in PVC raincoats, especially concerning environmental and safety standards. For example, the European Union has stringent REACH regulations that govern chemical substances. Research the specific requirements for your target market, including labeling and compliance certifications. Working with suppliers familiar with these regulations can help ensure your products meet necessary standards. -

What common issues should I be aware of when ordering custom PVC raincoats?

Common issues include discrepancies in product quality, delays in production or shipping, and miscommunication regarding design specifications. To mitigate these risks, establish clear communication channels and set realistic timelines. Implement a robust contract that outlines quality expectations, penalties for delays, and procedures for handling defects. Conduct regular check-ins during the production process to address any concerns promptly.

تنويه هام وشروط الاستخدام

⚠️ تنويه مهم ⚠️

المعلومات الواردة في هذا الدليل، بما في ذلك المحتوى المتعلق بالمصنعين والمواصفات الفنية وتحليل السوق، هي لأغراض إعلامية وتعليمية فقط. وهي لا تشكل مشورة مهنية في مجال المشتريات أو مشورة مالية أو مشورة قانونية.

على الرغم من أننا بذلنا كل جهد ممكن لضمان دقة المعلومات ودقة توقيتها، إلا أننا لسنا مسؤولين عن أي أخطاء أو سهو أو معلومات قديمة. تخضع ظروف السوق وتفاصيل الشركة والمعايير الفنية للتغيير.

يجب على المشترين بين الشركات إجراء العناية الواجبة المستقلة والشاملة الخاصة بهم قبل اتخاذ أي قرارات شراء. ويشمل ذلك الاتصال بالموردين مباشرة، والتحقق من الشهادات، وطلب عينات، وطلب الاستشارات المهنية. يتحمل القارئ وحده مخاطر الاعتماد على أي معلومات واردة في هذا الدليل.

Top 4 Custom Pvc Raincoat Manufacturers & Suppliers List

1. Aakasha – Black Hooded Maxi Raincoat

المجال: etsy.com

مسجل: 2004 (21 سنة)

مقدمة: Black Hooded Maxi Raincoat: Eco Leather Belt, Extravagant Trench – Sale Price: $139.89 (Original Price: $174.87, 20% off) – Seller: Aakasha

Red Glossy Vinyl Trench Coat: Double-Breasted PVC Fashion Outerwear – Sale Price: $104.25 (Original Price: $139.00, 25% off) – Seller: mikawimstore

Falcon industrial thick rubber rain jacket with hood – Price: $20.00 – Unisex

Vintage men’s yellow pvc raincoat …

2. Tehachapi Sportsman Club – Custom Waterproof Raincoat

المجال: tehachapisportsmanclub.com

مسجل: 2006 (19 سنة)

مقدمة: This company, Tehachapi Sportsman Club – Custom Waterproof Raincoat, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Anadin Crafts – Custom PVC Raincoats & Jackets

المجال: in.pinterest.com

مسجل: 2009 (16 سنة)

مقدمة: This company, Anadin Crafts – Custom PVC Raincoats & Jackets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

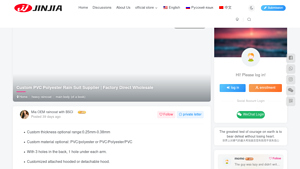

4. JJ Raincoat – Custom PVC Polyester Rain Suits

المجال: jjraincoat.com

مسجل: 2023 (2 سنة)

مقدمة: Custom PVC Polyester Rain Suit Supplier | Factory Direct Wholesale. Custom thickness optional range: 0.25mm-0.38mm. Custom material optional: PVC/polyester or PVC/Polyester/PVC. Features: 3 holes in the back, 1 hole under each arm, attached or detachable hood, two outside pockets with flaps, snap front closure, optional reflective strips. Recommended for outdoor activities, ideal for motorcyclists…

Strategic Sourcing Conclusion and Outlook for custom pvc raincoat

In the evolving landscape of custom PVC raincoat sourcing, understanding the unique needs of diverse international markets is paramount. Buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly prioritizing durability, customization, and sustainability in their procurement strategies. By focusing on strategic sourcing, businesses can leverage competitive pricing and quality assurance, ensuring their offerings meet the high expectations of end consumers.

One key takeaway is the importance of establishing strong relationships with reliable manufacturers who can provide innovative solutions tailored to local climates and cultural preferences. Engaging with suppliers who prioritize environmentally-friendly materials can also enhance brand reputation and compliance with international standards.

Looking ahead, the demand for custom PVC raincoats is set to grow as industries recognize the value of protective gear across various sectors, from outdoor recreation to industrial applications. International buyers are encouraged to explore partnerships that not only fulfill their immediate needs but also align with long-term sustainability goals. By taking proactive steps in their sourcing strategies, companies can position themselves favorably in a competitive marketplace. Embrace the opportunity to innovate and secure your supply chain today for a resilient future.