Introduction: Navigating the Global Market for custom pvc raincoat

In today’s rapidly evolving global market, sourcing high-quality custom PVC raincoats presents unique challenges for B2B buyers, particularly those operating in diverse climates across Africa, South America, the Middle East, and Europe. With varying consumer preferences and the need for durable, weather-resistant materials, navigating the complexities of this product category can be daunting. This comprehensive guide will explore the different types of custom PVC raincoats available, their diverse applications in industries ranging from agriculture to outdoor recreation, and the critical factors to consider when vetting suppliers.

Understanding the nuances of custom PVC raincoats is essential for making informed purchasing decisions. Throughout this guide, we will provide actionable insights into selecting the right specifications, assessing cost implications, and evaluating supplier reliability. By leveraging these insights, international B2B buyers can confidently navigate the sourcing process, ensuring that they secure products that not only meet their operational needs but also adhere to quality and sustainability standards.

As you delve into this guide, you will gain the knowledge necessary to identify the best custom PVC raincoat solutions tailored to your market demands. Whether you are a buyer in Germany seeking eco-friendly materials or a distributor in Brazil looking for competitive pricing, this resource will empower you to make strategic purchasing decisions that enhance your business’s resilience in an unpredictable global landscape.

기사 탐색

- Top 3 Custom Pvc Raincoat Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom pvc raincoat

- Understanding custom pvc raincoat Types and Variations

- Key Industrial Applications of custom pvc raincoat

- 3 Common User Pain Points for ‘custom pvc raincoat’ & Their Solutions

- Strategic Material Selection Guide for custom pvc raincoat

- In-depth Look: Manufacturing Processes and Quality Assurance for custom pvc raincoat

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom pvc raincoat’

- Comprehensive Cost and Pricing Analysis for custom pvc raincoat Sourcing

- Alternatives Analysis: Comparing custom pvc raincoat With Other Solutions

- Essential Technical Properties and Trade Terminology for custom pvc raincoat

- Navigating Market Dynamics and Sourcing Trends in the custom pvc raincoat Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom pvc raincoat

- 중요 고지 사항 및 이용 약관

- Strategic Sourcing Conclusion and Outlook for custom pvc raincoat

Understanding custom pvc raincoat Types and Variations

| 유형 이름 | 주요 차별화 기능 | 주요 B2B 애플리케이션 | 구매자를 위한 간략한 장단점 |

|---|---|---|---|

| Heavy Duty PVC Raincoats | Thick, durable material; often one-piece design | Industrial work, outdoor events | 장점: Excellent protection; long-lasting. 단점: Can be bulky and heavy. |

| Lightweight PVC Raincoats | Thinner material; often designed for ease of movement | Retail, promotional events | 장점: Comfortable; easy to pack. 단점: Less durable than heavy-duty options. |

| Custom Printed PVC Raincoats | Branding options available; various colors and designs | Marketing, corporate giveaways | 장점: Enhances brand visibility; customizable. 단점: May require minimum order quantities. |

| Insulated PVC Raincoats | Layered with insulation for colder climates | Outdoor sports, cold weather work | 장점: Provides warmth; versatile. 단점: Heavier and may limit breathability. |

| Eco-Friendly PVC Raincoats | Made from recycled materials; biodegradable options | Sustainable brands, eco-conscious businesses | 장점: Appeals to eco-friendly consumers; innovative. 단점: May come at a higher price point. |

What are the Characteristics and Suitability of Heavy Duty PVC Raincoats?

Heavy-duty PVC raincoats are constructed from thick, robust material, often featuring a one-piece design that provides comprehensive coverage. These raincoats are particularly suitable for industrial work environments, outdoor events, and situations requiring maximum protection against the elements. When considering a purchase, B2B buyers should evaluate the specific durability requirements of their industry, as well as the potential for wear and tear in demanding conditions. While these raincoats offer long-lasting protection, they can be bulkier and heavier than lighter alternatives.

How Do Lightweight PVC Raincoats Compare for Versatile Use?

Lightweight PVC raincoats are designed for comfort and ease of movement, making them ideal for retail and promotional events. Their thinner material allows for greater flexibility and packability, catering to businesses that need a practical solution for unexpected weather. Buyers should consider the trade-off between comfort and durability, as these raincoats may not withstand prolonged exposure to harsh conditions as well as heavy-duty options. However, their lightweight nature makes them a favorite for casual use and temporary outdoor activities.

What Advantages Do Custom Printed PVC Raincoats Offer?

Custom printed PVC raincoats provide businesses with an excellent opportunity for branding, allowing for various colors and designs that can showcase logos or marketing messages. These raincoats are particularly effective for corporate giveaways and promotional events, enhancing brand visibility in outdoor settings. B2B buyers should be mindful of minimum order quantities and potential lead times associated with customization, but the investment can yield significant returns in brand recognition. The ability to combine functionality with marketing makes these raincoats a popular choice among businesses.

Why Choose Insulated PVC Raincoats for Cold Weather Applications?

Insulated PVC raincoats are specifically designed for colder climates, featuring an additional layer of insulation to keep the wearer warm. These raincoats are suitable for outdoor sports and work environments where both rain and cold temperatures are a concern. When purchasing insulated options, B2B buyers should assess the balance between insulation and breathability, as heavier materials can restrict movement. While they provide excellent warmth, the added weight may be a consideration for those needing mobility.

What Makes Eco-Friendly PVC Raincoats a Smart Choice for Sustainable Brands?

Eco-friendly PVC raincoats are produced from recycled materials and may include biodegradable options, appealing to businesses focused on sustainability. These raincoats are increasingly popular among eco-conscious brands looking to align their products with environmental values. Buyers should consider the potential for a higher price point but can leverage the growing consumer demand for sustainable products. The innovative nature of these raincoats can also enhance a company’s reputation as a responsible business, making them a worthwhile investment.

Key Industrial Applications of custom pvc raincoat

| 산업/섹터 | Specific Application of custom pvc raincoat | 비즈니스를 위한 가치/혜택 | 이 애플리케이션의 주요 소싱 고려 사항 |

|---|---|---|---|

| 농업 | Protective wear for farmers during wet seasons | Enhances worker safety and comfort, reducing downtime | Durability, breathability, and customization options |

| 건설 | Rain gear for outdoor workers and site managers | Minimizes weather-related disruptions, ensuring productivity | Compliance with safety standards and availability |

| 식품 가공 | Hygiene protection for workers in wet environments | Maintains food safety standards and worker hygiene | Chemical resistance and ease of cleaning |

| 물류 및 운송 | Rain protection for delivery personnel | Protects goods and improves employee morale | Lightweight materials and effective waterproofing |

| 이벤트 관리 | Uniforms for outdoor event staff | Enhances brand visibility while ensuring staff comfort | Custom branding options and color choices |

How Is Custom PVC Raincoat Used in Agriculture?

In the agricultural sector, custom PVC raincoats are essential for protecting farmers and agricultural workers during wet seasons. These raincoats provide a waterproof barrier, ensuring that workers remain dry while tending to crops or livestock. The benefits include enhanced safety, reduced risk of illness from exposure to wet conditions, and increased productivity due to less downtime. For international buyers, especially in regions like Africa and South America, sourcing raincoats that are durable and breathable is crucial, as local climates can vary significantly.

What Role Does Custom PVC Raincoat Play in Construction?

Construction sites often face unpredictable weather, making custom PVC raincoats vital for outdoor workers and site managers. These raincoats help minimize weather-related disruptions, allowing projects to continue smoothly despite rain. They also contribute to worker safety by providing visibility and protection from the elements. For buyers in Europe, particularly in countries like Germany, compliance with local safety standards is a key consideration when sourcing these products, alongside the need for customization to meet specific site requirements.

Why Are Custom PVC Raincoats Important in Food Processing?

In the food processing industry, custom PVC raincoats serve a critical role in maintaining hygiene standards. Workers in wet environments require protective gear that is not only waterproof but also resistant to chemicals and easy to clean. This ensures that food safety standards are upheld while protecting employees from contamination. For international buyers, particularly in regions with stringent food safety regulations, sourcing raincoats that meet these specific requirements is essential for compliance and operational efficiency.

How Do Custom PVC Raincoats Benefit Logistics and Transport?

In logistics and transport, custom PVC raincoats are used by delivery personnel to protect themselves and the goods they handle from rain. This protective wear not only safeguards products but also boosts employee morale by ensuring comfort in adverse weather conditions. For businesses in the Middle East and Europe, sourcing lightweight yet effective waterproof materials is crucial for optimizing delivery operations, especially in regions prone to sudden weather changes.

What Advantages Do Custom PVC Raincoats Offer in Event Management?

For event management, custom PVC raincoats are utilized as uniforms for outdoor event staff, providing both protection from the elements and brand visibility. These raincoats can be customized with logos and colors to enhance branding while ensuring staff comfort during rainy events. For B2B buyers in Africa and South America, sourcing raincoats that offer both style and functionality can significantly improve the overall experience at outdoor events, making it a worthwhile investment.

3 Common User Pain Points for ‘custom pvc raincoat’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

문제: One of the most pressing issues for B2B buyers of custom PVC raincoats is the inconsistency in quality across different suppliers. This inconsistency can lead to significant operational challenges, especially in industries where safety and durability are paramount, such as construction and outdoor services. A buyer may place a large order based on a supplier’s sample, only to find that the bulk shipment does not meet the same quality standards. This not only affects their reputation but can also lead to costly returns and customer dissatisfaction.

솔루션: To mitigate this risk, buyers should prioritize sourcing from established manufacturers with a proven track record. Conduct thorough research and request certifications that validate the quality of materials used in their PVC raincoats. Implement a multi-supplier strategy to diversify risk; this allows buyers to compare products and ensure that they can rely on at least one supplier for consistent quality. Furthermore, establishing quality control protocols, such as regular inspections and random sample testing of shipments, can help maintain high standards and avoid costly discrepancies.

Scenario 2: Limited Customization Options

문제: Buyers often encounter limitations in customization options when sourcing custom PVC raincoats. This can hinder branding efforts, especially for companies looking to differentiate themselves in competitive markets. A buyer may find that while a supplier offers a range of colors and sizes, they lack the ability to print logos or specific designs, which are crucial for promoting brand identity during events or in the field.

솔루션: To address this pain point, buyers should clearly define their customization needs upfront and communicate these requirements during the sourcing process. Seek suppliers that specialize in custom orders and inquire about their capabilities regarding printing and design options. Additionally, consider suppliers that utilize advanced printing technologies, such as digital printing, which can accommodate intricate designs without significantly raising costs. Establishing a partnership with a supplier that values creativity and flexibility in customization can lead to more innovative solutions and a stronger brand presence.

Scenario 3: Poor Communication and Responsiveness

문제: Effective communication is essential in any B2B transaction, yet many buyers experience delays and poor responsiveness from suppliers of custom PVC raincoats. This can lead to misunderstandings regarding order specifications, delivery timelines, and pricing, which ultimately disrupts business operations. For instance, a buyer may find themselves waiting for extended periods for confirmation on an order or to receive updates on shipment status, which can impact project timelines and customer satisfaction.

솔루션: To improve communication and ensure timely responses, buyers should establish clear lines of communication with their suppliers from the outset. This includes setting expectations regarding response times and preferred communication methods, whether through email, phone, or dedicated platforms. Utilizing project management tools can also facilitate better tracking of orders and enhance transparency between both parties. Regular check-ins and updates can help maintain momentum and ensure that any potential issues are addressed proactively, fostering a more reliable and efficient partnership.

Strategic Material Selection Guide for custom pvc raincoat

When selecting materials for custom PVC raincoats, it is crucial to consider various factors that impact performance, durability, and compliance with international standards. Below is an analysis of four common materials used in the production of custom PVC raincoats, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of PVC for Raincoats?

Polyvinyl chloride (PVC) is a widely used material for raincoats due to its excellent waterproofing capabilities. PVC raincoats typically exhibit a temperature tolerance ranging from -10°C to 60°C, making them suitable for various climates. They also have good pressure resistance, which is essential for maintaining integrity under heavy rainfall. The material is inherently resistant to corrosion, making it ideal for environments with exposure to chemicals or saltwater.

What Are the Pros and Cons of Using PVC?

장점: PVC raincoats are known for their durability and cost-effectiveness. They can withstand wear and tear, making them suitable for heavy-duty applications. Additionally, the manufacturing process for PVC is relatively straightforward, allowing for mass production and customization options.

단점: However, PVC can be less breathable than other materials, which may lead to discomfort in hot climates. Furthermore, while the initial cost is low, the environmental impact of PVC production and disposal can be a concern for eco-conscious buyers.

How Does EVA Compare as an Alternative Material?

Ethylene-vinyl acetate (EVA) is another material gaining traction in the raincoat market. It offers excellent flexibility and a softer feel compared to PVC, making it more comfortable for extended wear. EVA also has a wider temperature range, withstanding temperatures as low as -40°C and as high as 80°C.

장점: The lightweight nature of EVA makes it ideal for lightweight raincoats, and its resistance to UV light helps prevent degradation over time.

단점: However, EVA may not be as durable as PVC, particularly in high-stress applications. It is generally more expensive, which could be a limitation for budget-conscious buyers.

What About PU Coated Fabrics?

Polyurethane (PU) coated fabrics are another option for custom raincoats. These fabrics are often combined with a base material like polyester or nylon, providing a balance of flexibility and durability. PU offers excellent water resistance and breathability, making it suitable for warmer climates.

장점: The breathability of PU can enhance comfort, particularly for active wearers. It also has good abrasion resistance, making it suitable for rugged outdoor activities.

단점: The downside is that PU-coated fabrics can be more expensive than PVC and may require more complex manufacturing processes. Additionally, they may not perform as well in extreme conditions.

What Are the Considerations for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of compliance with local standards such as ASTM, DIN, and JIS. For example, buyers from Germany may prioritize materials that meet stringent EU regulations on environmental impact, while those in Brazil may focus on cost-effectiveness and availability. Understanding regional preferences and regulations can significantly influence material selection.

Summary Table of Material Selection for Custom PVC Raincoats

| 재료 | Typical Use Case for custom pvc raincoat | 주요 이점 | 주요 단점/제한 사항 | 상대적 비용(낮음/중간/높음) |

|---|---|---|---|---|

| PVC | Heavy-duty rain protection in industrial settings | Durable and cost-effective | 통기성 저하, 환경 문제 | 낮음 |

| EVA | Lightweight rainwear for casual use | Flexible and comfortable | Less durable, higher cost | Med |

| PU Coated Fabric | Active wear in warm climates | Breathable and abrasion-resistant | Higher cost, complex manufacturing | 높음 |

This strategic material selection guide provides B2B buyers with the insights needed to make informed decisions when sourcing custom PVC raincoats, ensuring they meet both performance and compliance standards for their target markets.

In-depth Look: Manufacturing Processes and Quality Assurance for custom pvc raincoat

What Are the Main Stages in the Manufacturing Process of Custom PVC Raincoats?

The manufacturing of custom PVC raincoats involves several critical stages, each designed to ensure that the final product meets the specific needs of B2B buyers. Understanding these stages can help buyers assess potential suppliers and their capabilities.

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of PVC materials. High-quality PVC is sourced based on the desired specifications such as thickness, durability, and flexibility. Manufacturers typically conduct material tests to ensure that the PVC meets industry standards and customer requirements. This stage may also involve the addition of additives to enhance properties such as UV resistance and flame retardancy.

2. Forming

In the forming stage, the prepared PVC material is processed using techniques such as extrusion or calendaring. Extrusion involves melting the PVC and forcing it through a die to create sheets or films of the desired thickness. Alternatively, calendaring rolls the PVC into sheets, ensuring uniform thickness. This stage is crucial as it determines the raincoat’s physical properties, such as weight and flexibility.

3. Assembly

The assembly stage involves cutting the formed PVC into patterns and sewing or welding them together to create the raincoat. Advanced sewing techniques, including reinforced seams, ensure durability and water resistance. For designs that require seamless construction, high-frequency welding may be employed, which uses heat to bond PVC layers without stitching, enhancing waterproof capabilities.

4. Finishing

Finishing touches are applied to the raincoat to enhance its usability and aesthetics. This may include adding features such as hoods, pockets, or reflective strips for safety. The final product is also subjected to surface treatments to improve texture and appearance. At this stage, quality checks are conducted to ensure that the raincoat meets design specifications and functional requirements.

How Is Quality Assurance Implemented in Custom PVC Raincoat Production?

Quality assurance is a vital component of the manufacturing process, especially for B2B buyers who require reliable and consistent products. The following outlines the key aspects of quality control in the production of custom PVC raincoats.

Relevant International Standards and Industry-Specific Certifications

To ensure quality, manufacturers should comply with international standards such as ISO 9001, which outlines requirements for quality management systems. Additionally, industry-specific certifications like CE marking indicate that the product meets European safety and health standards. For buyers in sectors like oil and gas, compliance with API standards may also be necessary.

주요 품질 관리 체크포인트는 무엇인가요?

Quality control checkpoints are integral to maintaining product integrity throughout the manufacturing process. The following checkpoints are commonly employed:

-

수신 품질 관리(IQC): This initial checkpoint assesses the quality of raw materials upon delivery. Suppliers should provide material certifications to verify compliance with specified standards.

-

IPQC(인프로세스 품질 관리): During production, IPQC monitors key parameters such as material thickness, seam strength, and waterproofing capabilities. Regular inspections at this stage help catch defects early.

-

최종 품질 관리(FQC): At the end of the manufacturing process, a comprehensive inspection is performed to ensure that the raincoat meets all specifications, including size, color, and functionality. Random sampling techniques may be used to test finished products.

What Common Testing Methods Are Used in Quality Assurance for PVC Raincoats?

Various testing methods are employed to evaluate the performance and safety of custom PVC raincoats. Key testing methods include:

-

방수 테스트: To verify the waterproofing capabilities, manufacturers may conduct hydrostatic pressure tests, which measure how much water pressure the fabric can withstand without leaking.

-

Tensile Strength Testing: This test assesses the fabric’s strength and durability by measuring how much force it can withstand before breaking.

-

UV Resistance Testing: Given the exposure to sunlight, testing for UV resistance is essential to ensure the material will not degrade over time.

-

Flame Retardancy Testing: For raincoats intended for industrial use, manufacturers may perform flame retardancy tests to ensure compliance with safety regulations.

B2B 구매자는 공급업체의 품질 관리 프로세스를 어떻게 확인할 수 있나요?

B2B buyers must take proactive steps to verify the quality control processes of potential suppliers. Here are actionable strategies:

-

Conduct Supplier Audits: Regular audits can help buyers assess suppliers’ compliance with quality standards. This may involve visiting manufacturing facilities to evaluate processes, equipment, and personnel qualifications.

-

Request Quality Assurance Reports: Suppliers should provide documentation of their quality assurance processes, including test results and compliance certifications. This transparency helps buyers gauge the reliability of the supplier.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can be conducted at various stages of production, ensuring adherence to agreed-upon standards.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe must navigate specific quality control nuances when sourcing custom PVC raincoats. Key considerations include:

-

Understanding Regional Standards: Different countries may have varying regulations regarding product safety and quality. Buyers should familiarize themselves with local standards to ensure compliance.

-

Cultural and Communication Differences: Effective communication is crucial in international transactions. Buyers should establish clear specifications and expectations to avoid misunderstandings.

-

Logistical Considerations: Quality control does not end with production. B2B buyers should consider logistics, including transportation and storage conditions, which can impact product integrity.

In conclusion, a thorough understanding of manufacturing processes and quality assurance practices is essential for B2B buyers looking to procure custom PVC raincoats. By focusing on these aspects, buyers can make informed decisions and foster successful partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom pvc raincoat’

In the competitive landscape of sourcing custom PVC raincoats, a structured approach can significantly enhance your procurement process. This checklist is designed to guide B2B buyers through essential steps, ensuring you make informed decisions and secure high-quality products.

1단계: 기술 사양 정의

Clearly outline the specifications for your custom PVC raincoats, including material thickness, waterproofing capabilities, and design features such as hoods or reflective strips. This step is vital as it sets the foundation for your sourcing process. Consider the end-use environment—whether for industrial, outdoor, or promotional purposes—as it will influence your requirements.

- 소재 품질: Specify the type of PVC (e.g., eco-friendly or heavy-duty) to ensure it meets your durability needs.

- Customization Options: Decide on colors, sizes, and branding elements that reflect your company’s identity.

2단계: 잠재적 공급업체 조사

Conduct thorough research to identify suppliers who specialize in custom PVC raincoats. Look for companies with a proven track record in manufacturing and delivering similar products to your target market.

- Industry Experience: Prefer suppliers with experience in your specific sector or region, as they are more likely to understand local regulations and customer preferences.

- Online Reviews and Ratings: Utilize platforms like Alibaba or industry-specific forums to gauge supplier reputations.

3단계: 공급업체 인증 평가

Before engaging with a supplier, verify their certifications and compliance with relevant industry standards. This ensures the products you receive are safe and of high quality.

- Quality Management Systems: Check for ISO certifications that indicate adherence to quality control practices.

- Environmental Compliance: Look for certifications related to environmental sustainability, especially if eco-friendly materials are a priority.

4단계: Request Samples

Always request samples before finalizing your order. This step is crucial for assessing the quality and functionality of the raincoats firsthand.

- Test Durability: Evaluate the material’s strength and waterproof capabilities under real-world conditions.

- Review Customization: Ensure that the branding and design elements meet your specifications and expectations.

5단계: 약관 및 가격 협상

Engage in discussions with potential suppliers to negotiate pricing, minimum order quantities, and delivery terms. Effective negotiation can lead to better pricing and favorable terms that suit your budget and timelines.

- 볼륨 할인: Inquire about bulk order discounts to maximize cost savings.

- 결제 약관: Clarify payment options, including deposits and payment schedules.

6단계: Finalize Logistics and Delivery

Coordinate logistics for the shipping and delivery of your custom PVC raincoats. This includes selecting the right shipping method and confirming delivery timelines to ensure timely receipt.

- Shipping Methods: Evaluate options such as air freight for faster delivery or sea freight for cost-effectiveness, depending on your urgency.

- 세관 및 관세: Be aware of import regulations and potential customs duties that may apply when sourcing from international suppliers.

7단계: Establish Quality Control Measures

Implement quality control protocols to ensure that the delivered products meet your specifications and quality standards. This step is essential for maintaining your brand’s reputation.

- Inspection Procedures: Develop a checklist for inspecting the quality of received goods.

- 피드백 메커니즘: Create a process for providing feedback to suppliers based on product performance and quality issues.

By following this practical sourcing guide, B2B buyers can navigate the complexities of procuring custom PVC raincoats effectively, ensuring quality products that meet their specific needs.

Comprehensive Cost and Pricing Analysis for custom pvc raincoat Sourcing

When sourcing custom PVC raincoats, understanding the comprehensive cost structure and pricing dynamics is crucial for B2B buyers. The cost components and price influencers can significantly impact the overall expenditure and affect your sourcing strategy.

What are the Key Cost Components in Custom PVC Raincoat Manufacturing?

The cost structure for custom PVC raincoats can be broken down into several key components:

-

자료: The primary material, PVC (Polyvinyl Chloride), varies in quality and price. High-grade PVC offers better durability and waterproofing but comes at a higher cost. Additional materials like zippers, buttons, and linings also contribute to the overall material cost.

-

노동: Labor costs can differ based on the manufacturing location. Regions with lower labor costs, such as certain countries in Asia, may offer more competitive pricing. However, the complexity of customization can increase labor hours, thus raising costs.

-

제조 오버헤드: This includes expenses related to factory operations, utilities, and administrative costs. Efficient production processes can help mitigate these overheads.

-

툴링: For custom designs, tooling costs for molds and other equipment can be significant. These costs are usually amortized over larger production runs, making them more manageable for bulk orders.

-

품질 관리(QC): Implementing rigorous QC measures ensures that the raincoats meet specified standards. This can add to the cost but is essential for maintaining quality, especially for international markets where standards may vary.

-

물류: Shipping costs can fluctuate based on the destination, weight, and volume. International buyers must consider customs duties, tariffs, and other import-related expenses.

-

마진: Suppliers typically add a profit margin to their costs. This margin can vary based on competition, market demand, and the perceived value of the product.

How Do Price Influencers Affect Custom PVC Raincoat Sourcing?

Several factors can influence the pricing of custom PVC raincoats:

-

볼륨/MOQ: Bulk orders generally lower the per-unit cost. Suppliers are often willing to offer discounts for larger minimum order quantities (MOQs), making it advantageous for buyers to plan for larger purchases.

-

사양/사용자 지정: Unique designs or specific features may lead to higher costs. Buyers should clearly outline their requirements to avoid unexpected charges.

-

재료 및 품질 인증: High-quality materials or certifications (like ISO or CE marks) can elevate prices but may be necessary for compliance in certain markets, particularly in Europe.

-

공급업체 요인: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their proven track record, while less-known suppliers might offer lower prices to attract business.

-

인코텀즈: The chosen Incoterm (e.g., FOB, CIF) affects shipping costs and responsibilities. Understanding these terms can help buyers avoid unexpected expenses.

What Are the Best Practices for Negotiating Prices on Custom PVC Raincoats?

-

Conduct Thorough Market Research: Understand the prevailing market rates and competitors’ offerings. This knowledge empowers you during negotiations.

-

볼륨 할인 활용: If possible, consolidate orders to meet MOQ thresholds, which can lead to significant savings.

-

총소유비용(TCO)에 집중하기: Look beyond the initial price. Consider factors like durability, maintenance, and potential returns when evaluating costs.

-

Be Aware of Pricing Nuances: International buyers should factor in exchange rates, potential tariffs, and shipping delays when assessing prices.

-

관계 구축: Establishing a good rapport with suppliers can lead to better pricing options and more favorable terms in the long run.

결론

Sourcing custom PVC raincoats involves navigating a complex cost structure and understanding various pricing influencers. By considering these elements and employing strategic negotiation tactics, international B2B buyers can optimize their sourcing decisions and achieve better value for their investments. Always remember to request indicative prices and be prepared for fluctuations based on market conditions.

Alternatives Analysis: Comparing custom pvc raincoat With Other Solutions

Exploring Alternatives to Custom PVC Raincoats for B2B Buyers

In the quest for effective rain protection solutions, B2B buyers often encounter several alternatives to custom PVC raincoats. Understanding these options is essential for making informed purchasing decisions that align with specific operational needs, budget constraints, and environmental considerations. Below, we compare custom PVC raincoats with two viable alternatives: breathable waterproof jackets and traditional rubber raincoats.

비교 표

| 비교 측면 | Custom PVC Raincoat | Breathable Waterproof Jacket | Traditional Rubber Raincoat |

|---|---|---|---|

| 성능 | Excellent water resistance; less breathable | Good water resistance; breathable | Good water resistance; less comfortable |

| 비용 | Moderate to high | Moderate | Low to moderate |

| 구현의 용이성 | Easy to procure and customize | Slightly complex due to sizing and material variations | Easy to find; limited customization |

| 유지 관리 | Low maintenance; easy to clean | Requires care to maintain breathability | Low maintenance; easy to clean |

| 모범 사용 사례 | Industrial and outdoor use | Outdoor activities, sports | General purpose, casual wear |

대안에 대한 자세한 분석

Breathable Waterproof Jackets

Breathable waterproof jackets are designed for high-performance applications, allowing moisture to escape while keeping the wearer dry. These jackets often use advanced materials, such as Gore-Tex, which provide excellent protection against rain while ensuring comfort through breathability. However, they can be more expensive than PVC raincoats and may require careful handling to maintain their waterproof properties. They are ideal for outdoor professionals who engage in physically demanding activities, such as hiking or construction, where comfort and mobility are crucial.

Traditional Rubber Raincoats

Traditional rubber raincoats offer a cost-effective solution for wet weather. Made from rubberized materials, these coats provide solid water resistance and are generally easy to clean. However, they often lack breathability, which can lead to discomfort during prolonged wear. While they are suitable for casual use and can be found at lower price points, they may not withstand the rigors of industrial environments as effectively as custom PVC raincoats. They are best suited for less demanding applications where budget constraints are a priority.

Conclusion: Choosing the Right Rain Protection Solution

When evaluating rain protection options, B2B buyers should consider the specific use case, budget, and environmental conditions. Custom PVC raincoats excel in demanding industrial settings, offering customization and durability. In contrast, breathable waterproof jackets are preferable for active outdoor use where comfort is paramount, while traditional rubber raincoats serve as a budget-friendly alternative for general purposes. By assessing these alternatives based on performance, cost, and maintenance, buyers can make informed decisions that meet their operational requirements and enhance their overall productivity.

Essential Technical Properties and Trade Terminology for custom pvc raincoat

What Are the Key Technical Properties of Custom PVC Raincoats?

When considering custom PVC raincoats for your business, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some key specifications to consider:

1. 재료 등급

The grade of PVC used in raincoats directly impacts durability, flexibility, and resistance to environmental factors. Higher-grade PVC, such as PVC 500D, offers superior tear resistance and longevity, making it ideal for heavy-duty applications. Buyers should assess material grades to ensure the raincoat meets specific operational needs, especially in rugged environments.

2. 방수 등급

This property indicates the level of water resistance a raincoat provides, typically measured in millimeters. A higher waterproof rating (e.g., 3000mm or above) signifies better protection against heavy rain. For B2B buyers, understanding waterproof ratings ensures that the raincoat meets industry standards and customer expectations for protection in adverse weather.

3. 통기성

Breathability refers to the fabric’s ability to allow moisture vapor to escape, which is essential for comfort during wear. Breathable materials help prevent overheating, making them preferable for active users. Buyers should evaluate breathability in conjunction with waterproof ratings to strike a balance between comfort and protection.

4. Weight and Thickness

The weight and thickness of the PVC material influence the raincoat’s overall feel and usability. Lighter materials may enhance mobility but could compromise durability, while thicker materials offer better protection at the cost of weight. It’s essential for B2B buyers to consider the intended use—such as outdoor activities or industrial applications—when selecting the appropriate weight and thickness.

5. Tolerance Levels

Tolerance levels refer to the permissible variations in dimensions during manufacturing. For custom raincoats, tighter tolerances ensure a better fit and improved functionality. Understanding tolerance specifications can help buyers avoid fit issues and ensure that the end product meets their exact requirements.

6. Color Fastness

Color fastness tests how well a fabric retains its color after exposure to various elements like sunlight and washing. High color fastness is critical for maintaining the aesthetic appeal of the raincoat, especially in industries where branding is essential. Buyers should inquire about color fastness ratings to ensure longevity and brand visibility.

What Are Common Trade Terms Relevant to Custom PVC Raincoats?

Understanding industry terminology is vital for effective communication and negotiation in the B2B space. Here are some essential trade terms:

1. OEM(주문자 상표 부착 생산)

An OEM is a company that produces products that are sold under another company’s brand. In the context of custom PVC raincoats, buyers can work with OEMs to create tailored designs that align with their brand identity. This term is crucial for buyers looking to establish unique product lines.

2. MOQ(최소 주문 수량)

MOQ refers to the minimum number of units that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory costs and ensure they can meet demand without overcommitting resources. This term often dictates purchasing strategies, especially for startups or small businesses.

3. RFQ(견적 요청)

An RFQ is a formal request sent to suppliers to obtain pricing and terms for specific products. For B2B buyers, submitting an RFQ for custom PVC raincoats allows them to compare options and negotiate better deals based on their requirements.

4. 인코텀즈(국제 상거래 약관)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping and delivery obligations. Familiarity with these terms is crucial for B2B buyers to avoid misunderstandings and ensure smooth logistics. For instance, terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact overall costs.

5. 리드 타임

Lead time is the period between placing an order and receiving the product. It is a critical factor for B2B buyers who need to plan their inventory and ensure timely delivery to customers. Understanding lead times helps in managing expectations and operational planning.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can enhance their procurement strategies for custom PVC raincoats, ensuring they make informed decisions that align with their business needs.

Navigating Market Dynamics and Sourcing Trends in the custom pvc raincoat Sector

What Are the Current Market Trends in the Custom PVC Raincoat Sector?

The custom PVC raincoat market is experiencing dynamic shifts driven by various global factors. As climate change intensifies, the demand for reliable protective wear has surged, particularly in regions prone to heavy rainfall, such as parts of Africa and South America. The rise in extreme weather events has prompted businesses and consumers alike to invest in durable, waterproof clothing solutions. Furthermore, the COVID-19 pandemic accelerated the adoption of e-commerce and digital sourcing platforms, allowing B2B buyers from Europe and the Middle East to access a broader range of suppliers efficiently.

Emerging technologies are also influencing sourcing trends within this sector. Innovations in manufacturing processes, such as automated cutting and digital printing, have improved customization capabilities while reducing lead times. Buyers are increasingly looking for suppliers who can offer quick turnaround times without compromising quality. Additionally, the growing trend towards personalization in fashion has led to an uptick in demand for unique designs and branding options in custom PVC raincoats.

How Are Sustainability and Ethical Sourcing Influencing the Custom PVC Raincoat Market?

Sustainability has become a cornerstone of purchasing decisions in the custom PVC raincoat sector. B2B buyers are increasingly aware of the environmental impact of their sourcing practices, leading to a greater emphasis on ethical supply chains. The production of PVC can be associated with significant environmental concerns, including pollution and resource depletion. Therefore, suppliers that prioritize eco-friendly materials and sustainable manufacturing processes are gaining a competitive edge.

To appeal to environmentally conscious buyers, manufacturers are exploring alternatives such as recycled PVC and bio-based materials. Certifications like Global Recycled Standard (GRS) and OEKO-TEX can provide assurance regarding the environmental and social responsibility of the sourcing practices. Furthermore, establishing transparent supply chains is crucial; buyers are looking for suppliers who can demonstrate ethical labor practices and minimize their carbon footprint.

What is the Historical Context of the Custom PVC Raincoat Market?

The custom PVC raincoat has evolved significantly since its inception in the early 20th century. Initially developed for industrial applications, PVC raincoats gained popularity among outdoor enthusiasts and workers needing protection from the elements. Over the decades, advancements in PVC technology have improved the material’s durability, flexibility, and comfort, making it a preferred choice for both functional and fashion-oriented applications.

As consumer preferences have shifted towards personalized and branded apparel, manufacturers began offering customized options that cater to specific market needs. This evolution has been further accelerated by globalization, allowing international buyers to access diverse designs and manufacturing capabilities, thereby expanding their product offerings in local markets. Today, the custom PVC raincoat market stands at the intersection of functionality, fashion, and sustainability, driven by a complex interplay of consumer demand, technological advancements, and environmental consciousness.

Frequently Asked Questions (FAQs) for B2B Buyers of custom pvc raincoat

-

How do I ensure the quality of custom PVC raincoats when sourcing from suppliers?

To ensure quality, start by conducting thorough research on potential suppliers. Request samples of their PVC raincoats to assess material quality, durability, and craftsmanship. Look for certifications that indicate compliance with international standards, such as ISO or CE marks. Establish clear quality assurance protocols in your contract, including testing procedures and acceptable defect rates. Regular communication and on-site inspections during production can further ensure that the final product meets your expectations. -

What customization options are available for B2B buyers of PVC raincoats?

Customization options typically include size, color, logo printing, and additional features like pockets or reflective strips. Some suppliers may offer bespoke designs to meet specific functional requirements or branding needs. Discuss your requirements with potential suppliers to understand their capabilities and limitations. Ensure that your customization requests align with the supplier’s manufacturing processes to avoid delays or increased costs. -

What are the minimum order quantities (MOQs) for custom PVC raincoats?

Minimum order quantities can vary significantly between suppliers, often depending on the complexity of the design and customization options. On average, MOQs range from 100 to 1,000 units. It’s crucial to clarify MOQs upfront to avoid unexpected costs or commitment issues. Some suppliers may offer flexibility for first-time orders or smaller businesses, so be sure to negotiate based on your specific needs. -

What payment terms should I expect when sourcing PVC raincoats internationally?

Payment terms can vary widely based on the supplier and your negotiation power. Common terms include a deposit (usually 30-50%) upfront, with the balance due before shipment. For larger orders, suppliers may offer letter of credit (LC) options to mitigate risk. Always confirm payment methods accepted (e.g., bank transfer, PayPal) and ensure they are secure. Additionally, discussing payment terms in advance can prevent misunderstandings later in the transaction. -

How can I vet suppliers for custom PVC raincoats effectively?

To vet suppliers, start by checking their business credentials, including registration and licensing. Look for reviews and testimonials from other B2B buyers, and consider requesting references. Conduct factory audits or utilize third-party inspection services to assess their production capabilities. Ensure they have a reliable supply chain for raw materials and can meet your delivery timelines. Establishing a good rapport and clear communication can also indicate a supplier’s reliability. -

What logistics considerations should I keep in mind for shipping PVC raincoats?

Logistics considerations include shipping methods, costs, and lead times. Determine whether air freight or sea freight is more suitable based on your urgency and budget. Factor in customs duties and import regulations specific to your country, as these can impact total costs. Collaborate with logistics partners who have experience in handling textile products to ensure compliance and timely delivery. Tracking shipments and having contingency plans for delays can also enhance your supply chain efficiency. -

What are the most common uses for custom PVC raincoats in various industries?

Custom PVC raincoats are widely used in sectors such as construction, agriculture, and outdoor events due to their durability and waterproof properties. In construction, they protect workers from rain while maintaining visibility. In agriculture, they serve as protective gear for farmers during wet conditions. For outdoor events, they can be branded for promotional purposes while keeping attendees dry. Understanding your industry’s specific needs can help tailor your sourcing strategy effectively. -

How do I handle potential disputes with suppliers regarding custom PVC raincoats?

Handling disputes requires clear communication and documentation of all agreements. Establish a detailed contract outlining terms, responsibilities, and quality expectations. If a dispute arises, attempt to resolve it amicably through discussions. If necessary, refer to mediation or arbitration as stipulated in your contract. Maintaining a professional relationship can often lead to quicker resolutions, and having clear terms can protect you from future issues.

중요 고지 사항 및 이용 약관

⚠️ 중요 고지 사항

제조업체, 기술 사양 및 시장 분석에 관한 내용을 포함하여 이 가이드에서 제공하는 정보는 정보 제공 및 교육 목적으로만 사용됩니다. 전문적인 조달 자문, 재무 자문 또는 법률 자문으로 간주되지 않습니다.

당사는 정보의 정확성과 시의성을 보장하기 위해 최선을 다했지만, 오류, 누락 또는 오래된 정보에 대해서는 책임을 지지 않습니다. 시장 상황, 회사 세부 정보 및 기술 표준은 변경될 수 있습니다.

B2B 구매자는 독립적이고 철저한 실사를 수행해야 합니다. 구매 결정을 내리기 전에 충분히 검토하세요. 여기에는 공급업체에 직접 연락하고, 인증을 확인하고, 샘플을 요청하고, 전문가 상담을 받는 것이 포함됩니다. 이 가이드의 정보에 의존하는 데 따른 위험은 전적으로 독자가 부담합니다.

Top 3 Custom Pvc Raincoat Manufacturers & Suppliers List

1. Etsy – PVC Raincoats

도메인: etsy.com

등록: 2004년(21년)

소개: This company, Etsy – PVC Raincoats, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Anadincrafts – Custom PVC Raincoats & Jackets

도메인: in.pinterest.com

등록: 2009년(16년)

소개: This company, Anadincrafts – Custom PVC Raincoats & Jackets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

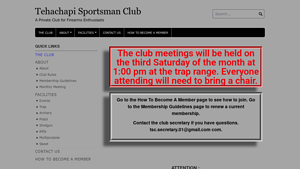

3. Tehachapi Sportsman Club – Custom Waterproof Raincoat

도메인: tehachapisportsmanclub.com

Registered: 2006 (19 years)

소개: This company, Tehachapi Sportsman Club – Custom Waterproof Raincoat, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for custom pvc raincoat

In the competitive landscape of custom PVC raincoat sourcing, strategic procurement plays a pivotal role in ensuring quality, cost-effectiveness, and sustainability. By leveraging local and global suppliers, businesses can mitigate risks associated with supply chain disruptions while enhancing product innovation. It is essential for B2B buyers to prioritize suppliers who demonstrate not only the capacity for customization but also adherence to environmental standards, given the increasing demand for eco-friendly products.

Moreover, understanding regional market trends and consumer preferences—especially in diverse markets like Africa, South America, the Middle East, and Europe—can significantly influence sourcing strategies. Engaging with manufacturers that offer flexible order quantities and rapid prototyping can further streamline the development process, allowing businesses to respond swiftly to market changes.

As we look ahead, the importance of strategic sourcing in the custom PVC raincoat sector cannot be overstated. International B2B buyers are encouraged to explore partnerships that prioritize innovation, sustainability, and reliability. By doing so, companies can position themselves to meet the evolving demands of their markets while ensuring the longevity and success of their product offerings. Embrace the future of sourcing—connect with reliable suppliers today to enhance your competitive edge.