Introduction: Navigating the Global Market for Hi Vis Raincoat

In an increasingly globalized market, sourcing high visibility raincoats that meet safety standards while ensuring comfort and durability can be a daunting challenge for international B2B buyers. This guide addresses the complexities involved in selecting the right hi vis raincoat by delving into various types, applications, and essential features that enhance visibility and protection in adverse weather conditions. With a focus on industries such as construction, transportation, and emergency services, understanding the nuances of hi vis rain gear is paramount for businesses operating in diverse climates across Africa, South America, the Middle East, and Europe.

This comprehensive resource equips procurement professionals with critical insights into supplier vetting processes, cost considerations, and compliance with regional safety standards. Whether you are navigating the market for ANSI Class-rated rain jackets or exploring options that incorporate advanced materials for enhanced waterproofing, this guide will empower you to make informed purchasing decisions. By addressing key factors such as fabric technology, reflective materials, and user comfort, we aim to simplify your sourcing journey and help you invest wisely in high visibility rainwear. As you explore the varied offerings available, you will gain the confidence needed to select products that not only meet safety requirements but also align with your organization’s operational needs.

Article Navigation

- Top 7 Hi Vis Raincoat Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for Hi Vis Raincoat

- Understanding Hi Vis Raincoat Types and Variations

- Key Industrial Applications of Hi Vis Raincoat

- 3 Common User Pain Points for ‘Hi Vis Raincoat’ & Their Solutions

- Strategic Material Selection Guide for Hi Vis Raincoat

- In-depth Look: Manufacturing Processes and Quality Assurance for Hi Vis Raincoat

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘Hi Vis Raincoat’

- Comprehensive Cost and Pricing Analysis for Hi Vis Raincoat Sourcing

- Alternatives Analysis: Comparing Hi Vis Raincoat With Other Solutions

- Essential Technical Properties and Trade Terminology for Hi Vis Raincoat

- Navigating Market Dynamics and Sourcing Trends in the Hi Vis Raincoat Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of Hi Vis Raincoat

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for Hi Vis Raincoat

Understanding Hi Vis Raincoat Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Class 3 Rain Jackets | Highest visibility with reflective material | Construction, roadwork, outdoor events | Pros: Maximum visibility; durable. Cons: Higher cost. |

| Class E Rain Pants | ANSI compliant with lower visibility standards | Warehousing, maintenance, logistics | Pros: Cost-effective; comfortable. Cons: Less visibility than Class 3. |

| Enhanced Visibility Rain Coats | Superior reflective striping and prismatic materials | Emergency services, roadside assistance | Pros: Enhanced visibility; versatile. Cons: Can be bulkier. |

| Flame-Resistant Hi Vis Rain Gear | Flame-resistant materials for hazardous environments | Oil & gas, electrical sectors | Pros: Safety against flames; compliance with industry standards. Cons: Higher price point. |

| Waterproof Rain Suits | Complete coverage with integrated designs | Maritime, heavy construction | Pros: Full-body protection; waterproof. Cons: Can be heavy and restrictive. |

What are Class 3 Rain Jackets and Their B2B Applications?

Class 3 rain jackets are designed to provide the highest level of visibility, featuring reflective materials that enhance safety in low-light or inclement weather conditions. These jackets are ideal for B2B applications in construction, roadwork, and outdoor events where worker visibility is critical. When purchasing, buyers should consider the durability of the materials, waterproofing capabilities, and comfort features to ensure employees remain safe and productive.

How Do Class E Rain Pants Compare in Visibility and Use?

Class E rain pants are ANSI compliant but offer lower visibility compared to Class 3 jackets. They are typically used in warehousing, maintenance, and logistics environments where high visibility is necessary but not as critical as in roadwork or construction. Buyers should evaluate the fit and comfort of these pants, especially for extended wear, as well as their waterproofing features to ensure that employees remain dry and comfortable.

What Makes Enhanced Visibility Rain Coats a Smart Choice?

Enhanced visibility rain coats incorporate superior reflective striping and sometimes prismatic materials that reflect light more effectively. These coats are particularly suited for emergency services and roadside assistance, where visibility can be a matter of safety. When selecting these products, B2B buyers should assess the level of visibility, breathability of the materials, and additional features like pockets and zippers for functionality in emergency scenarios.

Why Choose Flame-Resistant Hi Vis Rain Gear?

Flame-resistant hi vis rain gear is crucial for workers in hazardous environments like oil and gas or electrical sectors. This type of rain gear not only provides visibility but also protects against fire hazards. B2B buyers should consider compliance with industry safety standards, the weight of the materials, and the garment’s overall comfort, as well as its ability to withstand harsh weather conditions.

How Do Waterproof Rain Suits Provide Comprehensive Protection?

Waterproof rain suits offer complete coverage with integrated designs that protect against heavy rain and wind. They are commonly used in maritime operations and heavy construction where workers are exposed to the elements for extended periods. When purchasing these suits, B2B buyers should focus on the waterproof ratings, breathability, and ease of movement, ensuring that the suits do not hinder worker performance while providing necessary protection.

Key Industrial Applications of Hi Vis Raincoat

| Industry/Sector | Specific Application of Hi Vis Raincoat | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | On-site worker safety during inclement weather | Enhances visibility, reducing accident risks on construction sites | Compliance with ANSI standards; durability and waterproofing |

| Transportation & Logistics | Protecting workers in transit and loading areas | Improves safety for personnel working near moving vehicles | Lightweight materials; breathable fabrics for comfort |

| Oil & Gas | Safety for field workers in harsh weather conditions | Minimizes exposure to elements, reducing health risks | Flame-resistant options; high durability against harsh conditions |

| Utilities | Maintenance personnel visibility in adverse weather | Ensures quick identification of workers in emergency situations | Reflective materials; ANSI Class ratings for maximum visibility |

| Agriculture | Visibility for farm workers during rainy conditions | Reduces accidents in agricultural settings, enhancing safety | Breathable, waterproof materials; easy maintenance and cleaning |

How Is Hi Vis Raincoat Utilized in Construction Settings?

In the construction industry, Hi Vis raincoats are essential for ensuring worker safety during adverse weather conditions. These garments are designed to enhance visibility on-site, particularly when heavy machinery and traffic are involved. Workers equipped with high visibility rain gear are more easily seen by operators and drivers, significantly reducing the risk of accidents. For international buyers, sourcing options should prioritize ANSI compliance, ensuring that the raincoats meet safety regulations. Durability is also crucial, as construction sites often expose gear to wear and tear.

What Role Does Hi Vis Raincoat Play in Transportation and Logistics?

Within transportation and logistics, Hi Vis raincoats are vital for protecting workers involved in loading and unloading cargo, particularly in wet conditions. The bright colors and reflective strips ensure that personnel are visible to drivers and equipment operators, minimizing the risk of accidents. Buyers in this sector should consider lightweight and breathable materials, as workers may be active for extended periods. Additionally, garments should be easy to clean and maintain, given the nature of the job.

How Are Hi Vis Raincoats Essential for Oil & Gas Workers?

In the oil and gas sector, Hi Vis raincoats provide crucial protection for field workers who often operate in harsh weather conditions. These garments not only keep workers dry but also minimize health risks associated with cold and wet conditions. Flame-resistant options are particularly important for this industry, as workers may be exposed to hazardous materials. When sourcing Hi Vis raincoats, international buyers should ensure that the garments are made from high-durability materials that can withstand extreme environments.

Why Are Hi Vis Raincoats Important for Utility Workers?

Utility workers frequently operate in various weather conditions, making Hi Vis raincoats essential for their safety. These garments enhance visibility, especially during emergency repairs or maintenance work in adverse weather. Quick identification of workers can be crucial in preventing accidents. Buyers should focus on sourcing raincoats that utilize reflective materials and adhere to ANSI Class ratings to ensure maximum visibility and compliance with safety standards.

How Do Hi Vis Raincoats Benefit Agricultural Workers?

In agriculture, Hi Vis raincoats serve as a safety measure for farm workers during rainy conditions. The bright colors help improve visibility in the fields, reducing the likelihood of accidents while operating machinery or working near livestock. For international buyers, sourcing should prioritize breathable and waterproof materials to ensure comfort during long hours in the field. Additionally, ease of maintenance is a key consideration, as agricultural environments can be particularly dirty.

3 Common User Pain Points for ‘Hi Vis Raincoat’ & Their Solutions

Scenario 1: Ensuring Worker Visibility in Adverse Weather Conditions

The Problem: In regions prone to heavy rainfall, such as parts of Africa and South America, ensuring worker visibility during inclement weather is a significant challenge. B2B buyers often find that standard rain gear fails to provide adequate visibility and protection, leading to safety hazards on construction sites or in logistics operations. Workers may struggle to be seen by passing vehicles or heavy machinery, increasing the risk of accidents and injuries. Additionally, the lack of breathable materials can make workers uncomfortable, potentially leading to decreased productivity.

The Solution: To address visibility concerns, buyers should prioritize sourcing high visibility raincoats that meet or exceed ANSI Class 3 compliance standards, ensuring maximum reflectivity and visibility even in heavy downpours. When selecting raincoats, look for models that incorporate breathable fabrics, such as ripstop or Teflon-coated materials, which offer both waterproofing and comfort. Furthermore, consider investing in rain gear that features additional reflective striping or prismatic materials for enhanced visibility. Ensure that the rain gear fits well to promote ease of movement while maintaining a professional appearance. Implement regular training sessions for workers on the importance of wearing high visibility gear, especially during adverse weather conditions, to reinforce safety protocols.

Scenario 2: Managing Cost and Quality in Hi Vis Raincoat Procurement

The Problem: B2B buyers often face budget constraints while needing to purchase high-quality hi vis raincoats for their workforce. Compromising on quality for cost can lead to increased expenses in the long run due to frequent replacements and potential liability costs from accidents related to inadequate protection. Buyers may also struggle to assess the quality of rain gear without hands-on experience, making it difficult to ensure they are making the best investment.

The Solution: To navigate the balance between cost and quality, buyers should conduct thorough market research to compare different suppliers and their product offerings. Request samples from manufacturers to evaluate the material quality, waterproofing capabilities, and comfort before placing a bulk order. Buyers can also leverage bulk purchasing agreements or long-term contracts with suppliers to secure better pricing without sacrificing quality. Additionally, look for warranties or guarantees that indicate manufacturer confidence in their products. Establishing a consistent supplier relationship can foster better pricing and enhance the procurement process over time.

Scenario 3: Addressing Diverse Worker Needs and Preferences

The Problem: In a diverse workforce, individual needs and preferences for rain gear can vary significantly. Workers may have different requirements based on their roles, climate conditions, and personal comfort. A one-size-fits-all approach can lead to dissatisfaction, reduced morale, and ultimately, decreased safety compliance as workers may opt not to wear gear that doesn’t meet their personal preferences.

The Solution: B2B buyers should consider a range of hi vis raincoat options to cater to the diverse needs of their workforce. Conduct surveys or focus groups to gather feedback from employees about their preferences regarding fit, style, and functionality. Offering a selection of rain gear—such as lightweight jackets for warmer climates and insulated options for colder regions—can ensure that all workers feel comfortable and adequately protected. Additionally, consider incorporating customization options, such as adding company logos or personalized sizing, to enhance worker acceptance and pride in their safety gear. Providing training on the importance of wearing the appropriate gear, along with incentives for compliance, can further encourage a safety-first culture within the organization.

Strategic Material Selection Guide for Hi Vis Raincoat

When selecting materials for high visibility raincoats, several factors come into play, including performance characteristics, cost, and compliance with international safety standards. Here, we analyze four common materials used in the production of hi-vis raincoats, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Polyester in Hi Vis Raincoats?

Polyester is a widely used material in hi-vis raincoats due to its excellent durability and resistance to various environmental factors. It typically has a temperature rating of up to 100°C and can withstand moderate pressure without losing its integrity. Polyester is also resistant to shrinking and stretching, making it an ideal choice for garments that require longevity.

Pros: Polyester is cost-effective and readily available, which makes it a popular choice for manufacturers. Its lightweight nature contributes to wearer comfort, especially in warmer climates common in regions like Africa and South America.

Cons: While polyester has good water resistance, it may not be completely waterproof unless treated with additional coatings. Its breathability can also be limited, which might lead to discomfort in humid conditions.

How Does PVC Affect Performance in Hi Vis Raincoats?

Polyvinyl Chloride (PVC) is another material often used in hi-vis raincoats, particularly for heavy-duty applications. PVC raincoats can withstand extreme weather conditions, offering excellent water resistance and a temperature rating of up to 70°C. They are also resistant to corrosion, making them suitable for industrial environments.

Pros: The durability of PVC makes it ideal for heavy use, especially in sectors like construction and manufacturing. It is also relatively inexpensive, which appeals to budget-conscious buyers.

Cons: PVC can be less breathable than other materials, leading to discomfort during extended wear. Its rigidity may also limit mobility, making it less suitable for tasks requiring a high degree of flexibility.

What Role Does Nylon Play in Hi Vis Raincoat Construction?

Nylon is known for its strength and abrasion resistance, making it a favored material for hi-vis raincoats intended for rugged use. It typically has a temperature rating of around 90°C and offers good resistance to wear and tear.

Pros: The lightweight nature of nylon enhances comfort, and its ability to wick moisture away from the body makes it suitable for high-activity environments. Additionally, nylon can be treated to improve water resistance, making it versatile.

Cons: Nylon can be more expensive than polyester and PVC, which may be a consideration for cost-sensitive buyers. It may also be less effective in extreme cold conditions unless layered appropriately.

How Does the Use of Teflon Coating Enhance Hi Vis Raincoats?

Teflon-coated fabrics are increasingly popular in hi-vis raincoat manufacturing due to their superior water and stain resistance. Teflon can enhance the performance of base materials like polyester or nylon, allowing for better water repellency and easier cleaning.

Pros: The primary advantage of Teflon is its ability to keep the raincoat looking new longer, reducing maintenance costs for businesses. This feature is particularly appealing in regions with heavy rainfall, such as parts of Europe and South America.

Cons: Teflon coatings can increase production costs, which may deter some buyers. Additionally, the effectiveness of the coating can diminish over time, necessitating careful consideration of the garment’s lifespan.

Summary of Material Selection for Hi Vis Raincoats

| Material | Typical Use Case for Hi Vis Raincoat | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | General outdoor use | Lightweight and cost-effective | Limited waterproofing | Low |

| PVC | Heavy-duty industrial applications | Excellent water resistance | Less breathable and rigid | Low |

| Nylon | Rugged outdoor activities | Strong and abrasion-resistant | Higher cost and less cold-resistant | Med |

| Teflon Coated | High-performance rain protection | Superior water and stain resistance | Higher production costs | High |

This guide serves as a strategic resource for international B2B buyers, enabling informed decisions based on material properties, application suitability, and compliance with local standards. Understanding these factors is crucial for selecting the right hi-vis raincoat that meets safety and performance requirements across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for Hi Vis Raincoat

What Are the Main Stages in the Manufacturing Process of Hi Vis Raincoats?

The manufacturing process of hi vis raincoats consists of several key stages that ensure the final product meets industry standards for safety, visibility, and durability. Understanding these stages can help B2B buyers make informed decisions when sourcing raincoats for their workforce.

Material Preparation

The first stage involves the selection and preparation of materials. Hi vis raincoats are typically made from synthetic fabrics such as polyester or nylon, which provide waterproof properties. The material often undergoes a treatment process to enhance its water resistance and durability. Additionally, reflective materials are incorporated to meet visibility standards. Buyers should inquire about the fabric’s denier rating, as higher denier counts indicate increased strength and durability.

Forming

Once the materials are prepared, the next step is forming the raincoat components. This stage includes cutting the fabric into specific patterns that will be sewn together. Advanced cutting techniques, such as laser cutting, may be employed to ensure precision and reduce fabric waste. This is crucial, as accurate cuts lead to better fitting garments and less material loss, which can significantly affect production costs.

Assembly

The assembly stage is where the individual components come together to form the finished product. This typically involves stitching the fabric pieces using industrial sewing machines that can handle waterproof materials. Specialized techniques, such as welded seams or heat sealing, are often utilized to enhance waterproof capabilities and ensure that seams do not allow water penetration. B2B buyers should assess the sewing techniques used by suppliers to ensure they meet quality and durability standards.

Finishing

The final stage of manufacturing is finishing, which includes adding any additional features such as zippers, pockets, or adjustable cuffs. This stage also involves quality checks to ensure the garments meet specified design and safety standards. Buyers should be aware of the importance of finishing touches, as they can impact both the functionality and appearance of the raincoats.

What Quality Assurance Processes Are Relevant for Hi Vis Raincoats?

Quality assurance (QA) is critical in the manufacturing of hi vis raincoats, as it ensures that the products meet international and industry-specific standards. Understanding these processes can help B2B buyers assess potential suppliers effectively.

International Standards and Industry-Specific Certifications

For hi vis raincoats, adherence to international standards such as ISO 9001 is essential. This standard focuses on quality management systems and ensures that manufacturers consistently meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE marking in Europe or ANSI compliance in the United States are crucial. These certifications indicate that the raincoats meet safety and visibility standards necessary for use in hazardous work environments.

Key Quality Control Checkpoints

Quality control (QC) is integrated throughout the manufacturing process, with critical checkpoints established at various stages:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified quality standards. Buyers should verify that suppliers conduct thorough inspections of all incoming materials, including fabric and reflective materials.

-

In-Process Quality Control (IPQC): During assembly, periodic checks should be performed to identify any defects early in the process. This includes monitoring stitching quality, seam integrity, and overall construction. B2B buyers should request reports on IPQC measures to understand how suppliers maintain quality during production.

-

Final Quality Control (FQC): The final inspection occurs once the raincoats are fully assembled. This stage includes checking for visual defects, functionality of features like zippers, and compliance with safety standards. Comprehensive FQC processes help ensure that only products that meet quality benchmarks are shipped to customers.

What Common Testing Methods Are Used for Hi Vis Raincoats?

To ensure the functionality and safety of hi vis raincoats, various testing methods are employed:

-

Waterproof Testing: This test assesses the garment’s ability to withstand water penetration. Testing methods may include hydrostatic head tests, which measure the pressure at which water penetrates the fabric.

-

Reflectivity Testing: This involves evaluating the effectiveness of reflective materials under different lighting conditions. Proper reflectivity ensures that workers remain visible in low-light situations.

-

Durability Testing: This assesses how well the raincoat withstands wear and tear over time, including tests for abrasion resistance and seam strength. These tests are essential for ensuring that the product can endure harsh working conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is vital. Here are actionable steps to ensure that suppliers meet the necessary standards:

-

Conduct Supplier Audits: Regular audits can help assess a supplier’s adherence to quality standards and manufacturing processes. Buyers should consider scheduling on-site audits to evaluate production facilities and quality control measures.

-

Request Quality Reports: Suppliers should provide documentation detailing their quality control processes, including IQC, IPQC, and FQC reports. These documents can give buyers insights into the supplier’s commitment to quality.

-

Engage Third-Party Inspections: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. This can include pre-shipment inspections to verify that products meet specified standards before leaving the factory.

What Are the Nuances of Quality Control for International Buyers?

For buyers from regions such as Africa, South America, the Middle East, and Europe, it’s crucial to understand the nuances of quality control:

-

Regulatory Compliance: Different regions may have varying regulations regarding safety and quality standards. Buyers should familiarize themselves with local regulations and ensure that suppliers comply with both international and regional standards.

-

Cultural Differences: Understanding cultural nuances in business practices can help facilitate smoother communication with suppliers. This includes being aware of differing expectations regarding quality and timeliness in various regions.

-

Supply Chain Considerations: International logistics can introduce additional complexities in quality control. Buyers should ensure that suppliers have robust systems for tracking and managing quality throughout the supply chain, from raw material sourcing to final delivery.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for hi vis raincoats can empower B2B buyers to make informed decisions. By focusing on quality standards, testing methods, and supplier verification, buyers can ensure that they procure reliable, high-quality raincoats that enhance safety in hazardous work environments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘Hi Vis Raincoat’

In the competitive landscape of B2B procurement, sourcing high-visibility raincoats (Hi Vis Raincoats) effectively is crucial for ensuring safety and compliance in hazardous work environments. This guide provides a step-by-step checklist designed to assist international buyers in making informed decisions while sourcing Hi Vis Raincoats.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is fundamental to ensure that the Hi Vis Raincoats meet your operational needs. Consider factors such as material durability, waterproof ratings, and visibility standards (e.g., ANSI Class compliance). Identify any additional features required, such as flame resistance or breathability, which can affect worker comfort and safety.

- Materials: Look for options with high denier ratings (150D to 300D) to ensure robustness.

- Visibility: Ensure compliance with local and international visibility standards to maintain safety in low-light conditions.

Step 2: Assess Supplier Reputation

Before engaging with suppliers, conduct thorough research to evaluate their reputation in the market. Look for reviews, testimonials, and case studies from previous clients, particularly those in similar industries or regions. A supplier with a strong track record is more likely to provide reliable products and services.

- References: Request references from businesses in your industry to gauge supplier reliability.

- Certifications: Verify any relevant certifications that demonstrate the quality and safety of their products.

Step 3: Evaluate Product Range and Customization Options

Ensure that potential suppliers offer a diverse range of Hi Vis Raincoats to meet various needs. This includes different styles, sizes, and customization options, such as branded logos. A supplier that provides a wide selection can cater to specific requirements and preferences.

- Styles: Look for jackets, bibs, and suits to accommodate different working conditions.

- Customization: Assess the ability to add company branding for enhanced visibility and team cohesion.

Step 4: Request Samples for Quality Assessment

Request samples of Hi Vis Raincoats to evaluate their quality firsthand. This step is critical to ensure that the products meet your specifications and expectations regarding comfort, fit, and functionality.

- Testing: Test the samples under expected working conditions to assess waterproofing and breathability.

- Fit and Comfort: Ensure that the garments allow for ease of movement while providing adequate coverage.

Step 5: Compare Pricing and Payment Terms

Obtain detailed quotes from multiple suppliers to compare pricing structures. Look beyond the initial costs and consider the total cost of ownership, including shipping, duties, and potential bulk discounts. Additionally, clarify payment terms to ensure they align with your cash flow requirements.

- Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce overall costs.

- Payment Options: Assess the flexibility of payment terms offered by suppliers to facilitate smoother transactions.

Step 6: Review Delivery and Lead Times

Understanding delivery timelines is essential for planning and operations. Confirm suppliers’ lead times and their ability to meet your deadlines. A supplier that can guarantee timely delivery is invaluable, especially in industries where safety gear is urgently needed.

- Flexibility: Check if they can accommodate rush orders in case of urgent needs.

- Shipping Options: Evaluate available shipping methods to ensure they align with your delivery timelines.

Step 7: Negotiate Terms and Finalize the Agreement

Once you have selected a supplier, engage in negotiations to finalize terms. Discuss pricing, warranties, return policies, and after-sales support. A clear agreement helps prevent misunderstandings and ensures a smooth procurement process.

- Warranties: Ensure the supplier offers warranties that cover defects and durability.

- Support: Confirm the availability of customer support for any post-purchase inquiries or issues.

Following this checklist will empower you to make informed decisions when sourcing Hi Vis Raincoats, ensuring safety and compliance for your workforce.

Comprehensive Cost and Pricing Analysis for Hi Vis Raincoat Sourcing

What Are the Key Cost Components in Hi Vis Raincoat Production?

When sourcing Hi Vis raincoats, understanding the various cost components is essential for effective budgeting and pricing negotiation. The primary elements include:

-

Materials: The choice of fabric significantly impacts cost. High-denier polyester or nylon, which offer durability and waterproofing, are commonly used. Specialized materials, such as flame-resistant fabrics, can further increase costs.

-

Labor: Labor costs can vary based on the region of production. Countries with lower labor costs may offer competitive pricing, but this can affect quality. Skilled labor is often required for detailed work like seam sealing, which ensures waterproof performance.

-

Manufacturing Overhead: This encompasses expenses related to the factory’s operational costs, including utilities, equipment maintenance, and administrative expenses. Efficient production processes can help reduce these costs.

-

Tooling: Initial investments in molds and machinery for custom designs can be significant. For bulk orders, these costs can be amortized over a larger number of units, reducing the per-unit cost.

-

Quality Control (QC): Implementing strict quality control measures is vital for safety gear. QC processes ensure compliance with standards such as ANSI/ISEA 107, which can add to the overall cost but is necessary to guarantee product reliability.

-

Logistics: Shipping and handling costs can vary greatly depending on the distance from the manufacturer to the buyer, the mode of transport, and the chosen Incoterms. These factors should be carefully evaluated as they can significantly influence the final price.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. Understanding the standard markup in the industry can help buyers negotiate better.

How Do Price Influencers Affect Hi Vis Raincoat Sourcing?

Several factors influence the pricing structure of Hi Vis raincoats. Key influencers include:

-

Volume/MOQ: Suppliers often offer better pricing for larger orders. Minimum Order Quantities (MOQs) can vary, and negotiating lower MOQs might be possible for first-time buyers or long-term partnerships.

-

Specifications and Customization: Custom features such as additional pockets, specific color patterns, or branding can increase the price. Buyers should clarify their needs upfront to avoid unexpected costs later.

-

Materials and Quality Certifications: Higher-quality materials and certifications can lead to increased costs. Buyers should consider the balance between price and the long-term value of higher-quality products that may last longer and provide better safety.

-

Supplier Factors: The reliability, reputation, and location of the supplier can also influence pricing. Established suppliers may charge more due to their perceived quality and service levels, while newer suppliers might offer competitive rates to build their market presence.

-

Incoterms: Understanding Incoterms is crucial, as they define the responsibilities of buyers and sellers in shipping. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the overall cost structure.

What Negotiation Strategies Can Help B2B Buyers Achieve Cost-Efficiency?

B2B buyers can enhance cost-efficiency through strategic negotiation and a thorough understanding of total cost ownership (TCO). Here are actionable tips:

-

Research and Benchmarking: Gather data on market prices and supplier offerings. This knowledge empowers buyers during negotiations and helps establish realistic pricing expectations.

-

Leverage Long-Term Relationships: Establishing long-term partnerships with suppliers can lead to better pricing and terms. Suppliers may offer discounts or preferential treatment to loyal customers.

-

Consider Total Cost of Ownership: Evaluate not just the upfront price but also the longevity, maintenance, and potential replacement costs of raincoats. Investing in higher-quality products may yield savings in the long run.

-

Explore Local Suppliers: For international buyers, sourcing locally can reduce logistics costs and import duties. This approach can also enhance communication and responsiveness.

-

Be Open to Alternative Solutions: If a supplier cannot meet pricing expectations, explore alternative materials or designs that may align better with budget constraints without compromising safety and visibility.

Conclusion

While the indicative prices for Hi Vis raincoats can vary widely—ranging from approximately $40 to over $1,400 based on specifications and quality—buyers must conduct a comprehensive analysis of cost components and pricing influencers. With strategic negotiation and an understanding of the total cost of ownership, international B2B buyers can secure favorable terms while ensuring compliance with safety standards.

Alternatives Analysis: Comparing Hi Vis Raincoat With Other Solutions

When evaluating safety gear for outdoor work environments, it is essential to consider various options that enhance visibility and protection against adverse weather conditions. The Hi Vis Raincoat is a popular choice, but other alternatives may also meet specific needs for different industries and work conditions. This analysis aims to compare the Hi Vis Raincoat with alternative solutions, providing B2B buyers with valuable insights into the best options available.

| Comparison Aspect | Hi Vis Raincoat | Alternative 1: High Visibility Poncho | Alternative 2: Reflective Safety Vest |

|---|---|---|---|

| Performance | Excellent waterproofing and visibility; ANSI Class compliant | Good waterproofing; less coverage | Basic visibility; minimal weather protection |

| Cost | Moderate ($50-$150) | Low ($20-$50) | Low ($10-$30) |

| Ease of Implementation | Easy to wear; available in various sizes | Very easy; one size fits most | Simple to wear over any clothing |

| Maintenance | Requires regular cleaning; durable materials | Minimal maintenance; easy to clean | Very low maintenance; easily washable |

| Best Use Case | Ideal for construction, traffic management, outdoor events | Suitable for casual outdoor work, festivals | Best for low-risk environments, short-duration tasks |

What Are the Pros and Cons of Using a High Visibility Poncho?

The high visibility poncho serves as a lightweight alternative to traditional raincoats. Its design allows for easy wear over other clothing, making it versatile for various outdoor activities. The poncho typically offers good waterproofing and visibility, ensuring users remain safe in inclement weather. However, it does not provide the same level of coverage as a raincoat, which may expose the lower body to wet conditions. Additionally, its one-size-fits-most approach may not accommodate all body types, leading to potential fit issues.

How Does a Reflective Safety Vest Compare to a Hi Vis Raincoat?

Reflective safety vests are often used in low-risk environments where high visibility is crucial, such as roadwork or event management. They are lightweight, easy to put on over regular clothing, and provide basic visibility in daylight and low-light conditions. However, reflective vests offer minimal protection against the elements, particularly rain and cold temperatures. As a result, they are more suitable for short-duration tasks or situations where weather conditions are mild.

How Should B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate safety gear, B2B buyers should consider the specific requirements of their work environment. The Hi Vis Raincoat is an excellent choice for those needing comprehensive protection from rain and enhanced visibility in hazardous conditions. In contrast, options like high visibility ponchos or reflective safety vests may be more suitable for less demanding situations or where cost savings are a priority. Ultimately, the decision should factor in the nature of the work, environmental conditions, and the level of safety required for personnel. By aligning these elements with the right gear, businesses can ensure the safety and productivity of their teams while complying with regulatory standards.

Essential Technical Properties and Trade Terminology for Hi Vis Raincoat

What Are the Key Technical Properties of Hi Vis Raincoats?

When considering high visibility raincoats for your workforce, understanding their technical specifications is crucial. Here are some essential properties to look for:

1. Material Grade

Hi vis raincoats are typically made from polyester or nylon, with denier ratings (e.g., 150D to 300D) indicating the fabric’s thickness and durability. A higher denier rating usually means a more robust garment, which is essential in harsh working conditions. For B2B buyers, selecting the appropriate material grade ensures that the raincoat can withstand wear and tear while providing adequate protection against the elements.

2. Waterproof Rating

The waterproof rating is often measured in millimeters (mm), indicating the water column height a fabric can withstand before leaking. A rating of 5,000 mm or higher is typically recommended for outdoor work environments. This property is critical for ensuring that workers remain dry, which can enhance comfort and productivity. B2B buyers should prioritize garments that offer a reliable waterproof rating to reduce the risk of employee discomfort and potential health issues.

3. Breathability

Breathability is measured in grams per square meter (g/m²) and indicates how well moisture vapor can escape from the inside of the garment. A breathable fabric helps regulate body temperature and keeps workers comfortable during physical activities. For international B2B buyers, particularly in warmer climates, selecting breathable hi vis raincoats can significantly impact worker performance and satisfaction.

4. ANSI Compliance

The American National Standards Institute (ANSI) establishes visibility standards for safety apparel. Hi vis raincoats may be classified as ANSI Class 1, 2, or 3, with Class 3 providing the highest level of visibility. Compliance with these standards is essential for ensuring worker safety in high-risk environments. B2B decision-makers should verify that the products they purchase meet the necessary ANSI classifications to comply with local safety regulations.

5. Seam Construction

Seam construction techniques, such as heat-sealed or taped seams, enhance the waterproof capabilities of raincoats. These methods prevent water from penetrating through the seams, which is a common failure point in less durable garments. For buyers, understanding seam construction can guide the selection of high-quality raincoats that offer superior protection against water ingress.

What Are Common Trade Terms Related to Hi Vis Raincoats?

Navigating the procurement process for hi vis raincoats involves familiarizing yourself with industry-specific terminology. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of hi vis raincoats, an OEM might design and manufacture the raincoat, which is then branded by another company. Understanding OEM relationships can help buyers identify reliable suppliers and negotiate better terms.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell in a single order. This term is crucial for B2B buyers as it influences inventory management and cash flow. Understanding the MOQ can help businesses plan their purchases effectively and avoid overstocking or understocking issues.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, issuing an RFQ can streamline the procurement process and ensure competitive pricing for hi vis raincoats. It’s an essential step in sourcing quality products at the best price.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs, which is vital for B2B buyers involved in cross-border procurement of hi vis raincoats. Familiarity with Incoterms can help mitigate risks and avoid misunderstandings in international shipping.

5. Lead Time

Lead time is the period between placing an order and receiving the goods. It encompasses manufacturing, processing, and shipping times. For B2B buyers, understanding lead time is essential for inventory planning and ensuring that safety gear is available when needed, particularly in industries with strict safety regulations.

By grasping these technical properties and trade terms, international B2B buyers can make informed purchasing decisions that enhance workplace safety and compliance.

Navigating Market Dynamics and Sourcing Trends in the Hi Vis Raincoat Sector

What Are the Key Market Dynamics and Trends Influencing the Hi Vis Raincoat Sector?

The Hi Vis raincoat sector is experiencing significant growth driven by several global factors. Increased safety regulations across industries, especially in construction and transportation, are pushing demand for high-visibility gear. International markets, particularly in Africa, South America, the Middle East, and Europe, are witnessing a surge in infrastructure projects, necessitating the use of safety apparel that ensures worker visibility in adverse weather conditions. For B2B buyers, this means an expanding market with a variety of options that cater to specific needs, including enhanced visibility features and weather resistance.

Emerging technologies are also reshaping sourcing trends. Innovations in materials—such as breathable, waterproof fabrics and reflective technologies—are becoming essential selling points. Buyers are increasingly looking for products that not only meet safety standards but also enhance comfort and usability. Furthermore, the rise of e-commerce platforms is facilitating more efficient procurement processes, allowing businesses to source high-quality Hi Vis raincoats from a global pool of suppliers. This shift towards online purchasing is particularly relevant for international buyers who may face challenges in local markets.

How Is Sustainability Shaping the Sourcing of Hi Vis Raincoats in B2B?

Sustainability is becoming a critical factor in the procurement of Hi Vis raincoats. As environmental concerns gain traction, B2B buyers are prioritizing ethical sourcing and environmentally friendly materials. This includes a preference for manufacturers that use recycled or sustainably sourced materials, which can significantly reduce the carbon footprint associated with production.

Additionally, certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX Standard 100 are gaining importance in the procurement process. These certifications provide assurance that the materials used in the raincoats are not only safe for wearers but also produced in an environmentally conscious manner. For international buyers, particularly in regions like Africa and South America where environmental regulations are evolving, aligning with suppliers that emphasize sustainable practices can enhance brand reputation and customer loyalty.

Moreover, the integration of sustainability into the supply chain can lead to cost savings in the long run. By investing in durable, high-quality products, companies can reduce the frequency of replacements, ultimately lowering overall expenditure while adhering to environmental standards.

What Are the Historical Developments That Have Shaped the Hi Vis Raincoat Market?

The evolution of Hi Vis raincoats can be traced back to the growing emphasis on workplace safety in the late 20th century. Initially, safety gear was primarily functional, focusing on visibility and protection from the elements. However, as awareness of occupational hazards increased, manufacturers began to innovate, incorporating reflective materials and advanced waterproofing technologies.

By the early 2000s, the introduction of ANSI (American National Standards Institute) classifications set benchmarks for visibility and safety, further influencing design and manufacturing processes. This regulatory framework has since been adopted globally, shaping the standards for Hi Vis raincoats across various markets.

Today, the sector not only prioritizes safety and functionality but also embraces trends in fashion and comfort, responding to the needs of a modern workforce. This historical context is crucial for B2B buyers as it underscores the importance of compliance and innovation in sourcing decisions. Understanding these trends allows businesses to make informed choices that align with both safety regulations and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of Hi Vis Raincoat

-

How do I choose the right Hi Vis Raincoat for my team?

Selecting the right Hi Vis Raincoat involves considering several factors, including the level of visibility required, the climate conditions, and the specific job roles of your team members. Look for garments that meet ANSI Class 3 compliance for maximum visibility in hazardous environments. Additionally, consider features such as waterproofing, breathability, and the weight of the fabric. For colder climates, opt for insulated options. Review customer feedback and consult with suppliers to find the best fit for your specific needs. -

What are the key features to look for in a Hi Vis Raincoat?

Key features of a quality Hi Vis Raincoat include ANSI compliance for visibility, waterproof materials, sealed seams to prevent water ingress, and reflective striping for enhanced safety. Breathability is essential for comfort, especially in warmer climates. Additionally, consider the fit and style, such as longer coats for more coverage or lightweight options for ease of movement. Other features like pockets, hoods, and adjustable cuffs can add functionality based on the tasks performed by your team. -

What is the typical minimum order quantity (MOQ) for Hi Vis Raincoats?

The minimum order quantity (MOQ) for Hi Vis Raincoats can vary significantly between suppliers, typically ranging from 50 to 500 units. It’s essential to discuss MOQs directly with potential suppliers to understand their specific policies. Some manufacturers may offer flexibility for bulk orders or combined shipments with other safety gear. Additionally, inquire about lead times and production capacity to ensure they can meet your demand within your required timeframe. -

How can I ensure the quality of Hi Vis Raincoats when sourcing internationally?

To ensure quality when sourcing Hi Vis Raincoats internationally, start by vetting suppliers through references and customer reviews. Request product samples to evaluate the material, stitching, and overall craftsmanship. Verify that the products comply with relevant safety standards in your region, such as ANSI or EN standards. Establish clear quality assurance protocols and consider third-party inspections before shipment to mitigate risks associated with international trade. -

What are the payment terms commonly offered by Hi Vis Raincoat suppliers?

Payment terms for Hi Vis Raincoat suppliers can vary widely, but common practices include a 30% deposit upon order confirmation and the remaining balance before shipping. Some suppliers may offer net terms (e.g., Net 30 or Net 60) for established customers. It’s advisable to clarify payment options upfront, including accepted methods (such as wire transfers or credit cards) and any potential fees. Additionally, ensure that the payment terms align with your company’s cash flow and budgeting practices. -

What customization options are available for Hi Vis Raincoats?

Customization options for Hi Vis Raincoats often include adding your company logo, choosing colors, or selecting specific reflective striping patterns. Some suppliers also offer tailored sizing and modifications based on your team’s requirements. When discussing customization, inquire about the minimum order quantities required for custom orders, lead times, and any additional costs involved. Customization can enhance brand visibility while ensuring that the gear meets your operational needs. -

What are the logistics considerations when importing Hi Vis Raincoats?

Logistics considerations for importing Hi Vis Raincoats include selecting the right shipping method (air freight for speed or sea freight for cost-effectiveness), understanding customs regulations, and calculating import duties and taxes. Collaborate with a freight forwarder who can guide you through the shipping process and ensure compliance with local regulations. Additionally, consider the supplier’s shipping capabilities, lead times, and whether they offer drop shipping directly to your location to streamline the process. -

How can I assess supplier reliability when sourcing Hi Vis Raincoats?

Assessing supplier reliability involves researching their business history, customer reviews, and industry reputation. Request references from previous clients and verify their ability to meet delivery schedules and quality standards. Engaging in open communication during the negotiation phase can also provide insights into their responsiveness and professionalism. Certifications and compliance with international quality standards can further indicate a supplier’s reliability, ensuring they can meet your expectations consistently.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Hi Vis Raincoat Manufacturers & Suppliers List

1. Hi Vis Supply – Rain Gear

Domain: hivissupply.com

Registered: 2007 (18 years)

Introduction: Hi Vis Rain Gear includes a variety of waterproof and durable options such as rain jackets, pants, long raincoats, and bib style pants. Available colors are Yellow, Lime, or Orange, with options for standard silver reflective striping or prismatic reflective striping for enhanced visibility. Key products include: 1. DOME75 DYNAMIC Series Rain Tamer DRC3432 HiVis Class 3 Rain Jacket – MSRP: $67.99,…

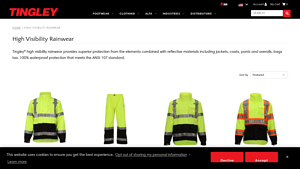

2. Tingley – High Visibility Rainwear

Domain: tingleyrubber.com

Registered: 1996 (29 years)

Introduction: High Visibility Rainwear from Tingley provides superior protection from the elements with reflective materials. Products include jackets, coats, pants, overalls, and bags. All items are 100% waterproof and meet ANSI 107 standards. Featured products include: Icon Jacket ($134.94 – $139.18), Icon LTE Pants ($62.30 – $66.54), Icon LTE Jacket ($121.46 – $125.70), Icon X-Back Jacket ($168.52 – $172.76)…

3. Hi-Viz – Tingley Eclipse Flame/Arc Resistant Rain Jacket

Domain: hi-viz.com

Registered: 2010 (15 years)

Introduction: High Visibility Rain Jackets available at Hi-Viz.com. Key products include: Tingley J44122/J44129 Eclipse Flame/Arc Resistant Hi-Vis Rain Jacket (from $132.19), Tingley C24122 Icon Coat (from $97.45), Tingley J23122 Vision Waterproof Jacket (from $56.23), Tingley C53122 Comfort-Brite Flame Resistant Coat (from $74.13), Portwest High Visibility Rain Jacket [US366] ($44.23), Radians RW10-3 Lightweig…

4. Blåkläder – Hi-Vis Rain Jacket

Domain: blaklader.com

Registered: 1998 (27 years)

Introduction: {“product_name”: “Hi-Vis Rain Jacket”, “brand”: “Blåkläder”, “article_number”: “43122003”, “price”: “129.95”, “currency”: “USD”, “color”: “Yellow Hi-viz/Black (3399)”, “sizes_available”: [“S”, “M”, “L”, “XL”, “XXL”, “XXXL”, “4XL”], “main_material”: “100% polyester, polyurethane coated”, “features”: [“windproof”, “waterproof”, “PU Coating”, “reflective details”, “fleece lined collar”, “removable ad…

5. Utility Pro – HiVis Rain Gear

Domain: utilityprowear.com

Registered: 2010 (15 years)

Introduction: UHV822 HiVis Waterproof Rain Jacket with Teflon™ Fabric Protector from $34.99, UHV823 Hi-Vis Utility Rain Pants $22.99, UHV600 HiVis Windbreaker with Teflon Fabric Protector $34.50 $39.99, UHV504 HiVis Bucket Hat $9.99 Sold out, UHV452P HiVis Pro Grade Rain Pants $49.99, UHVR642 HiVis Rain Jacket from $64.99 $104.99, UHV658 HiVis Pack Anorak $49.99, DryUp Rainwear Separates from $20.00 Sold out, U…

6. Lift Safety – Hi-Viz Apparel

Domain: liftsafety.com

Registered: 2005 (20 years)

Introduction: Hi-Viz Apparel includes various jackets, hoodies, vests, and t-shirts designed for visibility and safety in low light environments. Key products include:

1. Hi-Viz Yellow Bomber Jacket – Price: $75.00, Rating: 4.8/5.0 (4 reviews)

2. Hi-Viz Orange Bomber Jacket – Price: $75.00, Rating: 4.5/5.0 (11 reviews)

3. Hi-Viz Yellow Parka Jacket – Price: $75.00, Rating: 3.7/5.0 (23 reviews)

4. Hi-Viz Ora…

7. Hi Vis Rain Jacket – Class 3 Visibility

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Hi Vis Rain Jacket; Class 3 visibility; Colors: Orange/Lime/Yellow with reflective stripes; Quality water resistance; Fairly breathable; Recommendations include Showers Pass Hi-Vis jacket and ProViz Reflect360 CRS Plus Men’s Cycling Jacket.

Strategic Sourcing Conclusion and Outlook for Hi Vis Raincoat

In conclusion, strategic sourcing of high visibility raincoats presents a unique opportunity for international B2B buyers to enhance worker safety while maximizing operational efficiency. By investing in ANSI Class compliant rainwear, businesses can ensure that their workforce remains visible and protected in adverse weather conditions, particularly in hazardous environments typical of construction, transportation, and industrial sectors.

Buyers should prioritize sourcing high-quality materials that offer durability and waterproof capabilities, along with features such as reflective striping and breathable fabrics. These attributes not only enhance safety but also contribute to worker comfort, which can lead to improved productivity and reduced absenteeism.

As global markets continue to evolve, especially in regions like Africa, South America, the Middle East, and Europe, the demand for reliable safety gear will only increase. Now is the time to engage with reputable suppliers who can provide tailored solutions that meet specific regional needs and compliance standards.

Embrace the opportunity to partner with manufacturers committed to quality and innovation in high visibility rainwear. This strategic sourcing approach will position your organization as a leader in safety standards, ultimately leading to a more resilient and efficient workforce.