Introduction: Navigating the Global Market for heavy rubber raincoat

In the dynamic landscape of global commerce, sourcing heavy rubber raincoats presents unique challenges for international buyers. As businesses across diverse sectors—from agriculture to outdoor recreation—seek reliable protection against the elements, understanding the intricacies of this specialized product becomes paramount. This comprehensive guide serves as an essential resource for B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe, including markets such as Saudi Arabia and Germany.

The guide explores various types of heavy rubber raincoats, detailing their applications in different industries, from waterproof workwear for construction to durable outerwear for fishing and outdoor activities. It also addresses critical factors in supplier vetting, ensuring that buyers can identify trustworthy manufacturers that adhere to quality standards and ethical practices. Additionally, we provide insights into cost considerations, helping you navigate pricing structures and negotiate effectively.

By arming yourself with the knowledge contained in this guide, you will be empowered to make informed purchasing decisions that not only meet your operational needs but also enhance your brand’s reputation. Whether you’re looking to bulk purchase for a specific project or establish long-term supplier relationships, this resource is designed to streamline your sourcing process and mitigate risks associated with procurement in the heavy rubber raincoat market.

Article Navigation

- Top 7 Heavy Rubber Raincoat Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for heavy rubber raincoat

- Understanding heavy rubber raincoat Types and Variations

- Key Industrial Applications of heavy rubber raincoat

- 3 Common User Pain Points for ‘heavy rubber raincoat’ & Their Solutions

- Strategic Material Selection Guide for heavy rubber raincoat

- In-depth Look: Manufacturing Processes and Quality Assurance for heavy rubber raincoat

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘heavy rubber raincoat’

- Comprehensive Cost and Pricing Analysis for heavy rubber raincoat Sourcing

- Alternatives Analysis: Comparing heavy rubber raincoat With Other Solutions

- Essential Technical Properties and Trade Terminology for heavy rubber raincoat

- Navigating Market Dynamics and Sourcing Trends in the heavy rubber raincoat Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of heavy rubber raincoat

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for heavy rubber raincoat

Understanding heavy rubber raincoat Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Classic Rubberized Raincoat | Historical design, rubberized cloth, single-breasted closure | Historical reenactments, casual wear | Pros: Unique aesthetic, lightweight. Cons: Not fully waterproof. |

| Heavy Duty Waterproof Jacket | Engineered for extreme conditions, fully waterproof, breathable | Construction, fishing, outdoor work | Pros: Maximum protection, durable. Cons: Heavier than alternatives. |

| Fishing Anorak | Reinforced seams, adjustable features, often with hoods | Commercial fishing, marine operations | Pros: Designed for wet environments, flexible. Cons: May lack insulation for colder climates. |

| Insulated Rubber Raincoat | Combination of rubberized fabric with insulation | Cold-weather outdoor work, agriculture | Pros: Warmth and waterproofing. Cons: Bulkier, higher cost. |

| Lightweight Packable Raincoat | Compact design, easy to carry, often with quick-dry technology | Travel, emergency kits | Pros: Portable, versatile. Cons: Less durable for heavy-duty use. |

What Are the Characteristics of a Classic Rubberized Raincoat?

The Classic Rubberized Raincoat is characterized by its historical design and lightweight rubberized cloth. This type features a single-breasted closure and often includes period-accurate details, making it suitable for historical reenactments or casual wear. B2B buyers in sectors like theater, education, and specialty costume shops may find this option appealing due to its aesthetic value, though they should note that it is not fully waterproof, making it less suitable for heavy rain.

How Does a Heavy Duty Waterproof Jacket Stand Out?

Heavy Duty Waterproof Jackets are engineered for extreme environments, providing full waterproof capabilities and breathability. These jackets are often utilized in construction and outdoor work due to their robust construction and ability to withstand harsh weather. B2B purchasers in industries such as construction, agriculture, and emergency services prioritize these jackets for their durability and performance, although they may be heavier than other options, which could impact mobility.

Why Choose a Fishing Anorak for Marine Applications?

Fishing Anoraks are designed with reinforced seams and adjustable features, often including hoods to offer protection against splashes and rain. They are primarily used in commercial fishing and marine operations, where wet conditions are common. B2B buyers in the fishing industry should consider these anoraks for their flexibility and suitability for wet environments, but they may lack insulation, making them less ideal for colder climates.

What Are the Benefits of an Insulated Rubber Raincoat?

Insulated Rubber Raincoats combine waterproof rubberized fabric with thermal insulation, making them ideal for cold-weather outdoor work and agriculture. This type provides warmth alongside waterproofing, appealing to buyers in sectors where personnel are exposed to both rain and cold conditions. However, their bulkiness and higher cost may deter some buyers who prioritize lightweight options.

How Does a Lightweight Packable Raincoat Fit into B2B Needs?

Lightweight Packable Raincoats are designed for portability, featuring compact designs that make them easy to carry and store. They often utilize quick-dry technology, making them suitable for travel and emergency kits. B2B buyers in the travel industry or those supplying emergency preparedness gear may find these raincoats highly versatile. However, their reduced durability compared to heavier-duty options may limit their use in more demanding environments.

Key Industrial Applications of heavy rubber raincoat

| Industry/Sector | Specific Application of heavy rubber raincoat | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Crop Protection during Rainy Seasons | Protects workers from adverse weather, ensuring productivity | Durability, waterproofing, and ease of movement are crucial; consider local climate conditions. |

| Construction | Worker Safety on Job Sites | Enhances worker safety by keeping them dry, reducing illness and downtime | Compliance with safety regulations and durability for heavy-duty use are essential. |

| Fishing and Maritime | Protection for Crew in Harsh Conditions | Ensures crew safety and comfort, allowing them to focus on tasks without weather distractions | Sourcing should prioritize materials that withstand saltwater and heavy wear. |

| Oil & Gas | Maintenance and Safety in Harsh Environments | Reduces risk of exposure to hazardous conditions, promoting worker health | Look for high visibility options and compliance with industry safety standards. |

| Food Processing | Hygiene and Safety in Wet Environments | Ensures compliance with hygiene standards while protecting employees from wet conditions | Materials should be easy to clean and resistant to chemicals used in food processing. |

How is a Heavy Rubber Raincoat Used in Agriculture?

In agriculture, heavy rubber raincoats are essential during rainy seasons for protecting workers while tending to crops. These coats keep agricultural workers dry, which is crucial for maintaining productivity and preventing health issues related to exposure to wet conditions. Buyers in this sector should prioritize sourcing raincoats that offer durability and flexibility, allowing for ease of movement while working in the fields. Additionally, understanding local climate conditions can help in selecting the appropriate weight and waterproofing level of the garment.

What Role Does a Heavy Rubber Raincoat Play in Construction?

In the construction industry, heavy rubber raincoats are vital for ensuring worker safety on job sites, especially during inclement weather. These garments provide a barrier against rain, helping to minimize the risk of illness and accidents caused by slippery conditions. B2B buyers should focus on sourcing raincoats that comply with safety regulations and are designed for heavy-duty use, as construction environments can be harsh. Features such as reinforced seams and high visibility colors can further enhance worker protection.

Why are Heavy Rubber Raincoats Important in Fishing and Maritime Industries?

For the fishing and maritime industries, heavy rubber raincoats offer essential protection for crew members facing harsh weather conditions at sea. These coats help ensure safety and comfort, allowing crew members to focus on their tasks without the distraction of wet clothing. Buyers in this sector should prioritize materials that resist saltwater and are durable enough to withstand the rigors of maritime work. Additionally, sourcing options that provide insulation can be beneficial for cold-weather operations.

How Do Heavy Rubber Raincoats Enhance Safety in Oil & Gas Operations?

In the oil and gas industry, heavy rubber raincoats are crucial for maintaining safety and health standards in challenging environments. These coats protect workers from exposure to harsh weather conditions, reducing the risk of illness and promoting overall well-being. When sourcing raincoats for this sector, it’s important to consider high visibility options and ensure compliance with industry-specific safety standards. Durability and resistance to chemicals are also key factors that should influence purchasing decisions.

What Benefits Do Heavy Rubber Raincoats Provide in Food Processing Environments?

In food processing environments, heavy rubber raincoats are used to maintain hygiene and ensure worker safety in wet conditions. These coats protect employees from splashes and spills, allowing them to perform their duties without compromising cleanliness. B2B buyers should focus on sourcing raincoats made from materials that are easy to clean and resistant to chemicals commonly used in food processing. Ensuring compliance with health and safety regulations is also critical to protect both workers and the integrity of the food products.

3 Common User Pain Points for ‘heavy rubber raincoat’ & Their Solutions

Scenario 1: Sizing and Fit Issues with Heavy Rubber Raincoats

The Problem: One of the most common challenges faced by B2B buyers is ensuring that the heavy rubber raincoats fit their workforce properly. Many workers require additional layers underneath their rain gear, especially in colder climates, leading to potential sizing discrepancies. Inaccurate sizing can result in discomfort, reduced mobility, and ultimately, dissatisfaction with the product. If the raincoat is too tight, it restricts movement; if too loose, it can lead to chafing or even hinder safety when working in hazardous conditions.

The Solution: To address sizing issues, B2B buyers should prioritize sourcing from manufacturers who provide comprehensive sizing charts and fit guides. It is essential to conduct a survey of employee sizes before placing bulk orders. When possible, request sample sizes from suppliers to allow team members to try on various styles and fits. Additionally, consider investing in customizable options where possible. This proactive approach can help ensure that the selected raincoats accommodate both the workers’ needs and the layering they might require, promoting comfort and efficiency in the field.

Scenario 2: Durability and Weather Resistance Concerns

The Problem: In regions that experience extreme weather, particularly in Africa and South America, heavy rubber raincoats must withstand heavy rainfall and harsh conditions. B2B buyers often find that some products claim to be waterproof but fail to perform under prolonged exposure to heavy rain, leading to wet and uncomfortable workers. This situation can affect productivity and increase the risk of workplace accidents due to hypothermia or illness.

The Solution: To mitigate durability concerns, buyers should look for heavy rubber raincoats with verified waterproof ratings and durable construction materials. Research suppliers who utilize advanced manufacturing techniques, such as welded seams and high-quality rubber compounds, which enhance water resistance. Furthermore, seek out user reviews and case studies from other businesses that have tested the products in similar weather conditions. Establishing a relationship with reputable suppliers who offer warranties or guarantees can also provide peace of mind regarding product longevity and performance.

Scenario 3: Limited Versatility for Diverse Work Environments

The Problem: Many B2B buyers struggle with the versatility of heavy rubber raincoats, especially when their workforce operates in varied environments, from agricultural fields to industrial sites. A single style may not meet the diverse needs of all workers, leading to inefficiencies and the need to purchase multiple types of gear. This lack of versatility can also increase inventory costs and complicate the procurement process.

The Solution: To enhance versatility, buyers should seek heavy rubber raincoats that incorporate adjustable features such as removable liners, ventilation systems, and adaptable hoods. Multi-functional designs that can transition from casual work to more formal environments can also prove beneficial. When sourcing, consider suppliers who offer a range of styles that cater to different work conditions and individual preferences. Engaging in discussions with employees about their specific needs can inform purchasing decisions, ensuring that the selected raincoats effectively serve various roles while maintaining cost-effectiveness. Additionally, consider bulk purchasing agreements that allow for a mix of styles at a competitive price point.

Strategic Material Selection Guide for heavy rubber raincoat

When selecting materials for heavy rubber raincoats, it’s essential to consider various factors that influence performance, durability, and compliance with international standards. Below is an analysis of four common materials used in the production of heavy rubber raincoats, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Natural Rubber for Heavy Rubber Raincoats?

Natural rubber is derived from latex, making it a flexible and resilient material. It offers excellent elasticity and can withstand a wide range of temperatures, typically from -20°C to 80°C. Natural rubber also exhibits good resistance to abrasion and tearing, which is crucial for heavy-duty applications. However, it has limited resistance to UV light and ozone, which can lead to degradation over time.

Pros & Cons:

Natural rubber is durable and provides a comfortable fit due to its flexibility. However, it can be more expensive than synthetic alternatives and may require more complex manufacturing processes to enhance its UV resistance.

Impact on Application:

Natural rubber is suitable for environments where flexibility and comfort are paramount, such as agricultural or outdoor work. However, it may not be ideal for prolonged exposure to harsh UV conditions without proper treatment.

Considerations for International Buyers:

Buyers in regions like Africa and the Middle East should ensure compliance with local regulations regarding natural rubber sourcing and processing. Standards such as ASTM D2000 can guide quality expectations.

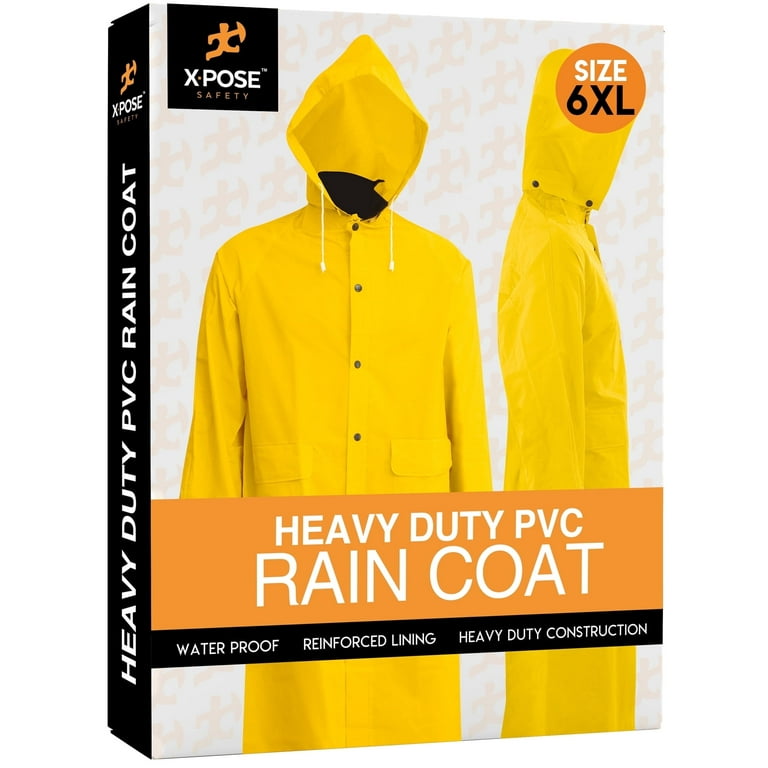

How Does PVC Compare as a Material for Heavy Rubber Raincoats?

Polyvinyl chloride (PVC) is a synthetic plastic polymer known for its waterproof properties. It is highly resistant to chemicals, oils, and UV light, making it an excellent choice for heavy-duty raincoats. PVC can typically withstand temperatures ranging from -10°C to 60°C.

Pros & Cons:

PVC is cost-effective and easy to manufacture, allowing for mass production. However, it can be less flexible than natural rubber, which may affect comfort and mobility. Additionally, PVC can be prone to cracking at low temperatures.

Impact on Application:

PVC raincoats are ideal for industrial applications where chemical exposure is a concern, such as in manufacturing or construction. However, they may not be suitable for environments requiring high flexibility.

Considerations for International Buyers:

Buyers in Europe and North America should ensure that PVC products meet compliance standards such as REACH or RoHS, which regulate harmful substances.

What Advantages Does Neoprene Offer for Heavy Rubber Raincoats?

Neoprene is a synthetic rubber that provides excellent waterproofing and insulation properties. It can withstand temperatures from -30°C to 100°C and is resistant to a variety of chemicals and oils. Neoprene is also known for its durability and resistance to UV light.

Pros & Cons:

The primary advantage of neoprene is its versatility and comfort, making it suitable for various applications, including extreme weather conditions. However, it tends to be more expensive than both natural rubber and PVC, which may impact budget considerations.

Impact on Application:

Neoprene is particularly effective in environments where both warmth and waterproofing are essential, such as in fishing or marine applications.

Considerations for International Buyers:

International buyers should verify that neoprene products comply with environmental standards, particularly in Europe, where regulations may restrict certain chemicals used in production.

How Does Polyurethane Enhance Heavy Rubber Raincoat Performance?

Polyurethane (PU) is another synthetic material that offers excellent waterproofing and breathability. It can handle a wide temperature range, typically from -20°C to 80°C, and is known for its durability and resistance to abrasion.

Pros & Cons:

PU raincoats are lightweight and flexible, providing a comfortable fit while still being robust. However, they can be more expensive than PVC and may require specialized manufacturing processes.

Impact on Application:

Polyurethane is well-suited for outdoor activities and professions where mobility and comfort are essential, such as hiking or construction work.

Considerations for International Buyers:

Buyers should ensure that PU products meet international standards such as DIN EN 343 for protective clothing against rain.

Summary Table of Material Selection for Heavy Rubber Raincoats

| Material | Typical Use Case for Heavy Rubber Raincoat | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Rubber | Agricultural work, outdoor activities | Excellent flexibility and comfort | Limited UV resistance | High |

| PVC | Industrial applications, construction | Cost-effective and chemical resistant | Less flexible, prone to cracking | Low |

| Neoprene | Marine applications, extreme weather | Superior waterproofing and insulation | Higher cost | High |

| Polyurethane | Outdoor activities, construction work | Lightweight and breathable | More expensive, specialized manufacturing | Medium |

This guide provides a comprehensive overview of material options for heavy rubber raincoats, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for heavy rubber raincoat

What Are the Key Stages in the Manufacturing Process of Heavy Rubber Raincoats?

Manufacturing heavy rubber raincoats involves a series of well-defined stages, each critical for ensuring the final product meets durability, functionality, and aesthetic standards. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Heavy Rubber Raincoats?

The process begins with the selection of high-quality rubberized materials that offer waterproofing and flexibility. Common materials include PVC, PU, and natural rubber blends, chosen for their resistance to harsh weather conditions. The preparation stage involves cutting the rubber into specified patterns, ensuring that all pieces are accurately sized for the final garment. This step may also include the treatment of materials to enhance their water-resistant properties.

What Techniques Are Used in Forming Heavy Rubber Raincoats?

Forming is the next crucial stage, where the cut rubber pieces are shaped into the desired raincoat design. Techniques such as heat sealing and welding are employed to bond the rubber components together without compromising their waterproof integrity. Heat sealing involves applying heat to the edges of the rubber pieces, causing them to melt and fuse, while welding uses high-frequency or ultrasonic waves to achieve a similar bond. The choice of technique often depends on the complexity of the design and the intended use of the raincoat.

How Are Heavy Rubber Raincoats Assembled?

Assembly follows the forming stage, where components such as sleeves, collars, and pockets are attached to the main body of the coat. This stage requires skilled labor to ensure that seams are reinforced and properly aligned. Special attention is given to stress points, which are prone to tearing, especially under heavy use. Quality stitching techniques, such as double-stitched seams, are commonly used to enhance durability and prevent leaks.

What Finishing Processes Are Applied to Heavy Rubber Raincoats?

Finishing processes involve the application of additional features that enhance the functionality and appearance of the raincoat. This may include the addition of reflective strips for visibility, waterproof zippers, and adjustable cuffs. The final product undergoes a thorough inspection to ensure that all features are properly integrated and that the coat meets the required specifications.

What Quality Assurance Measures Are Implemented in Heavy Rubber Raincoat Production?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that heavy rubber raincoats meet international standards and customer expectations. The QA process typically aligns with recognized international standards such as ISO 9001, which provides a framework for consistent quality management.

Which International Standards Should B2B Buyers Be Aware Of?

For B2B buyers, it’s essential to understand the relevant international and industry-specific standards. ISO 9001 ensures that manufacturers maintain high-quality processes throughout production. Additionally, certifications like CE mark in Europe or API standards in specific industries may also apply, depending on the intended use of the raincoat. Buyers should verify that their suppliers hold these certifications to ensure compliance with safety and quality standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are critical at various stages of production. Typically, these include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Regular checks during manufacturing help identify any deviations from quality standards early in the process.

- Final Quality Control (FQC): The finished products are thoroughly inspected for defects, functionality, and adherence to specifications before shipping.

These checkpoints help mitigate risks and ensure that only high-quality products reach the market.

What Common Testing Methods Are Used for Heavy Rubber Raincoats?

Several testing methods can be employed to evaluate the performance of heavy rubber raincoats. Common tests include:

- Waterproof Testing: This assesses the ability of the raincoat to resist water penetration under various conditions.

- Tensile Strength Testing: Measures the material’s resistance to being stretched or pulled apart, which is crucial for durability.

- Seam Strength Testing: Evaluates the strength of seams to ensure they can withstand stress without tearing.

- Thermal Stability Testing: Ensures that the material maintains its properties under varying temperature conditions.

B2B buyers should inquire about these testing methods to ensure that the products meet their specific requirements.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to verify the quality control practices of their suppliers. Here are several strategies:

- Supplier Audits: Conducting audits of the manufacturing facilities can provide insights into the operational processes and quality management systems in place. This can help buyers assess whether the supplier adheres to necessary quality standards.

- Quality Reports: Requesting regular quality reports from suppliers can help buyers stay informed about production quality and any issues that may arise.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the products and manufacturing processes, ensuring compliance with standards.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification. Variations in regulatory requirements, quality expectations, and environmental standards can impact sourcing decisions. Buyers should work closely with suppliers to ensure that products meet both local and international standards, which may vary significantly across different markets.

Additionally, understanding the logistics of shipping and compliance with customs regulations is vital for smooth transactions. It is advisable for buyers to establish clear communication channels with suppliers to facilitate a better understanding of these nuances.

Conclusion

Navigating the manufacturing processes and quality assurance measures for heavy rubber raincoats is essential for B2B buyers seeking reliable and high-quality products. By understanding the key stages of production, relevant international standards, and effective quality control practices, buyers can make informed decisions that align with their business needs. Engaging with reputable suppliers who prioritize quality assurance will lead to successful partnerships and high-performance products in the market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘heavy rubber raincoat’

In the dynamic world of B2B procurement, sourcing heavy rubber raincoats requires a thorough understanding of both product specifications and supplier capabilities. This guide provides a step-by-step checklist to help international buyers navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Establish clear specifications for the heavy rubber raincoats you intend to purchase. This includes material quality, weight, waterproof capabilities, and design features such as pockets and closures. Understanding these specifications ensures that you select a product that meets your operational needs and withstands the environmental conditions relevant to your market.

- Material Requirements: Specify whether you need rubberized cloth, PVC, or another material known for durability and waterproofing.

- Performance Criteria: Define the level of waterproofing required, considering the climates in regions such as Africa or Europe.

Step 2: Research Market Demand and Trends

Investigate the demand for heavy rubber raincoats in your target markets. Trends may vary significantly between regions, influencing styles, sizes, and functionalities. Understanding market preferences can guide your procurement decisions and inventory planning.

- Consumer Preferences: Identify whether there is a preference for traditional designs or modern features like lightweight materials.

- Seasonal Demand: Take note of seasonal variations in demand based on climatic conditions in regions like South America or the Middle East.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Analyzing supplier capabilities and reputation helps mitigate risks associated with product quality and delivery timelines.

- Certifications: Verify relevant certifications, such as ISO standards or industry-specific quality marks.

- Production Capacity: Assess whether the supplier can meet your order volumes and deadlines consistently.

Step 4: Request Samples for Quality Assessment

Always request samples before making bulk purchases. Evaluating samples allows you to assess the quality of materials, craftsmanship, and overall fit. This step is essential to ensure that the raincoats will perform as expected in real-world conditions.

- Durability Tests: Consider testing samples under various weather conditions to verify performance claims.

- Size and Fit: Check the sizing against your target market’s standards to ensure customer satisfaction.

Step 5: Negotiate Pricing and Terms

Once you identify potential suppliers, engage in negotiations regarding pricing, minimum order quantities, and payment terms. Understanding the total cost of ownership, including shipping and tariffs, is vital for accurate budgeting.

- Bulk Discounts: Inquire about pricing tiers based on order volume to optimize your procurement costs.

- Payment Flexibility: Discuss payment terms that align with your cash flow needs, such as net 30 or net 60 options.

Step 6: Confirm Logistics and Delivery

Discuss logistics and delivery timelines to ensure that the product can be delivered on schedule. Reliable shipping arrangements are crucial, especially when importing goods from international suppliers.

- Shipping Methods: Evaluate different shipping options based on cost and delivery speed.

- Customs Clearance: Ensure the supplier can assist with customs documentation to avoid delays at borders.

Step 7: Establish a Quality Assurance Process

Implement a quality assurance process to monitor the quality of the raincoats upon arrival. This step ensures that the products meet your specifications and reduces the risk of returns or customer dissatisfaction.

- Inspection Procedures: Develop a checklist for inspecting the raincoats upon receipt.

- Feedback Loop: Create a system for gathering feedback from end-users to inform future procurement decisions.

Following this checklist will help you navigate the complexities of sourcing heavy rubber raincoats, ensuring that you make informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for heavy rubber raincoat Sourcing

What Are the Key Cost Components in Sourcing Heavy Rubber Raincoats?

When sourcing heavy rubber raincoats, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The type of rubberized fabric significantly influences the cost. High-quality, durable materials like vulcanized rubber may incur higher costs but provide superior waterproofing and longevity compared to standard rubberized cloth.

-

Labor: Labor costs vary based on the manufacturing location. Countries with lower labor costs can reduce overall expenses, but this must be balanced against the potential impacts on quality.

-

Manufacturing Overhead: This encompasses utilities, rent, and indirect labor costs. Efficient factories with streamlined processes can help mitigate these expenses.

-

Tooling: Custom designs or features (like reinforced seams or specialized closures) require specific tooling, which can add to initial costs.

-

Quality Control (QC): Implementing rigorous QC measures is vital, especially for waterproof products. The costs associated with QC processes should be factored into the total cost structure.

-

Logistics: Shipping costs can vary widely depending on the supplier’s location and the buyer’s destination. Understanding Incoterms is crucial to determining who bears these costs.

-

Margin: Suppliers typically apply a markup to cover their costs and profit margins. Understanding this can help buyers negotiate better pricing.

How Do Price Influencers Affect Heavy Rubber Raincoat Costs?

Several factors influence the pricing of heavy rubber raincoats in the B2B market:

-

Volume/MOQ: Ordering larger quantities often leads to better pricing due to economies of scale. Buyers should assess their inventory needs to take advantage of bulk discounts.

-

Specifications/Customization: Custom features, such as specific colors, sizes, or additional functionalities, can increase costs. Buyers should evaluate whether these customizations are necessary for their market.

-

Material Quality/Certifications: Higher-quality materials and certifications (e.g., ISO standards) can raise prices but may be essential for compliance in certain markets.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more but often provide better quality assurance and service.

-

Incoterms: Understanding shipping terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact total landed costs. Buyers should clarify these terms to avoid unexpected expenses.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

To achieve cost-efficient sourcing of heavy rubber raincoats, buyers should consider the following strategies:

-

Negotiation: Open discussions with suppliers about pricing can yield discounts, especially when committing to long-term contracts or larger orders.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also the costs associated with shipping, warehousing, and potential returns. Evaluating TCO provides a clearer picture of the actual investment.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, tariffs, and import duties that could impact final costs.

-

Quality vs. Price Trade-off: While it can be tempting to opt for the lowest price, compromising on quality may lead to higher costs in the long run due to returns or replacements.

Disclaimer on Indicative Pricing

Pricing for heavy rubber raincoats can fluctuate based on market conditions, material availability, and supplier negotiations. The prices mentioned in this guide are indicative and should be confirmed with suppliers for accuracy. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing heavy rubber raincoat With Other Solutions

Understanding Alternatives for Heavy Rubber Raincoats in the Market

In the quest for effective rain protection, the heavy rubber raincoat stands as a traditional option. However, various alternatives have emerged that cater to different needs, preferences, and environments. This analysis will explore how heavy rubber raincoats compare to other viable solutions, including lightweight waterproof jackets and rubber ponchos. By understanding these options, B2B buyers can make informed decisions tailored to their specific operational requirements.

| Comparison Aspect | Heavy Rubber Raincoat | Lightweight Waterproof Jacket | Rubber Poncho |

|---|---|---|---|

| Performance | Good for light to moderate rain; not fully waterproof | Excellent waterproofing; breathable | Adequate for light rain; less durable |

| Cost | Moderate ($150 – $200) | Variable ($80 – $150) | Low ($30 – $60) |

| Ease of Implementation | Ready to wear | Requires proper sizing | Easy to use and store |

| Maintenance | Requires careful cleaning to maintain condition | Minimal maintenance required | Very low maintenance |

| Best Use Case | Historical reenactments, moderate outdoor activities | Construction sites, outdoor sports | Casual use, emergency kits |

What Are the Advantages and Disadvantages of Lightweight Waterproof Jackets?

Lightweight waterproof jackets have become a popular alternative due to their advanced materials and design. These jackets typically utilize breathable membranes, allowing moisture from the body to escape while keeping rain out. They are ideal for high-intensity activities, such as construction or outdoor sports, where comfort and mobility are essential. However, their performance can vary significantly based on the quality of materials used, and some may not offer the same durability against heavy wear and tear as rubber raincoats.

Why Choose Rubber Ponchos Over Heavy Rubber Raincoats?

Rubber ponchos are another alternative that offers easy wear and portability. They are typically less expensive and can be quickly put on in sudden rain showers, making them suitable for casual use or emergency kits. However, their lack of durability and fit can be a drawback, as they may not provide adequate protection during heavy downpours or rugged activities. For businesses looking for cost-effective solutions for occasional rain, ponchos could be a viable option, but they may not meet the standards of more demanding environments.

How to Make the Right Choice for Your Needs?

Choosing the right rain protection solution depends on several factors including the nature of the work environment, frequency of rain exposure, and budget constraints. B2B buyers should consider whether they need a product that offers superior waterproofing and durability, like a heavy rubber raincoat, or if a more flexible and lightweight option suits their operations better. For industries with high exposure to inclement weather, investing in high-quality waterproof jackets might yield better long-term results, while casual settings may benefit from the convenience of rubber ponchos.

In conclusion, understanding the strengths and weaknesses of each alternative will empower buyers to select the most appropriate solution for their specific operational needs, ensuring both performance and cost-effectiveness in their rain protection strategy.

Essential Technical Properties and Trade Terminology for heavy rubber raincoat

What Are the Key Technical Properties of a Heavy Rubber Raincoat?

When sourcing heavy rubber raincoats for B2B purposes, understanding the technical properties is essential for ensuring the product meets specific industry needs. Here are some critical specifications to consider:

1. Material Composition

The primary material used in heavy rubber raincoats is often a blend of natural rubber and synthetic polymers, such as PVC (polyvinyl chloride) or polyurethane. This combination provides durability, flexibility, and waterproof capabilities. Understanding the material composition allows buyers to evaluate the product’s performance in extreme weather conditions, making it crucial for industries like construction, fishing, and outdoor recreation.

2. Waterproof Rating

Waterproof ratings are typically measured in millimeters of water column resistance (mm H2O). A higher rating indicates greater waterproofing capabilities. For instance, a heavy rubber raincoat with a rating of 10,000 mm or more is suitable for heavy rainfall. This specification is vital for B2B buyers in sectors where workers are exposed to severe weather, as it ensures maximum protection and comfort.

3. Seam Construction

The method of seam construction affects the garment’s waterproofness and durability. Seams can be sewn or welded, with welded seams generally providing a higher level of waterproofing. Buyers should inquire about the seam construction to ensure that the raincoat can withstand prolonged exposure to wet conditions, minimizing the risk of leaks and enhancing longevity.

4. Weight and Flexibility

The weight of the raincoat is a critical factor for comfort and mobility. Heavy rubber raincoats should balance durability with a manageable weight to allow for ease of movement. A coat that is too heavy can lead to fatigue, while one that is too lightweight may sacrifice protection. Buyers must consider the end-use of the raincoat when evaluating its weight and flexibility.

5. Breathability

While waterproofing is essential, breathability is equally important to prevent overheating and moisture build-up inside the coat. Many heavy rubber raincoats incorporate breathable membranes or vents to facilitate air circulation. Understanding the breathability of the product can help buyers ensure that workers remain comfortable during prolonged wear in humid conditions.

6. Reinforcement Features

Reinforced areas, such as elbows, shoulders, and the tail split, enhance the coat’s durability by preventing wear at stress points. Buyers should look for heavy rubber raincoats that include these reinforcement features, as they are crucial for maintaining the integrity of the garment in demanding environments.

What Are Common Trade Terms in the Heavy Rubber Raincoat Industry?

Familiarity with trade terminology is essential for effective communication and negotiation in B2B transactions. Here are some key terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. In the context of heavy rubber raincoats, an OEM may provide specific components or entire garments tailored to a buyer’s specifications. Understanding OEM relationships can help buyers ensure quality and consistency in their products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product that a supplier is willing to sell. This term is critical for buyers to understand as it impacts inventory management and cost considerations. Knowing the MOQ helps businesses plan their purchases effectively, especially when looking to stock up on heavy rubber raincoats for seasonal demand.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products. In the heavy rubber raincoat industry, an RFQ can help buyers compare costs, specifications, and delivery times, enabling informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international trade. They cover aspects such as shipping, insurance, and customs duties. Understanding Incoterms is essential for B2B buyers to clarify costs and responsibilities in the procurement of heavy rubber raincoats from overseas suppliers.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. This term is crucial for B2B buyers, particularly in industries where timely delivery is essential for operations. Knowing the lead time for heavy rubber raincoats helps businesses manage their supply chains effectively.

6. Warranty and Guarantee

A warranty is a promise from the manufacturer regarding the quality and performance of the product, while a guarantee often refers to the return policy. Understanding these terms is important for buyers to assess the risk associated with their purchase of heavy rubber raincoats, ensuring they receive value for their investment.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the heavy rubber raincoat Sector

What are the Current Market Dynamics and Key Trends in the Heavy Rubber Raincoat Sector?

The heavy rubber raincoat market is experiencing a notable resurgence, driven by several global factors. Increasing rainfall patterns, a direct consequence of climate change, have heightened demand for durable and reliable rain protection across various industries, including construction, agriculture, and outdoor recreation. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking high-quality rain gear that can withstand extreme weather conditions. In regions like Saudi Arabia and Germany, where weather variability is pronounced, the need for robust raincoats is critical.

Emerging technologies are reshaping sourcing trends in the heavy rubber raincoat sector. The integration of advanced manufacturing techniques, such as 3D knitting and automated cutting, has led to improved product quality and reduced production times. Additionally, the rise of e-commerce platforms has made it easier for buyers to source products globally, enabling them to compare suppliers and make informed purchasing decisions. Businesses are also leveraging data analytics to forecast demand and optimize inventory management, ensuring they can meet the needs of their customers promptly.

Furthermore, customization options are becoming increasingly popular. Buyers are looking for raincoats that can be tailored to specific industry requirements, whether it’s enhanced waterproofing for maritime applications or lightweight designs for outdoor sports. As a result, suppliers who can offer flexible manufacturing and quick turnaround times are gaining a competitive edge in this dynamic market.

How is Sustainability and Ethical Sourcing Impacting B2B in the Heavy Rubber Raincoat Sector?

Sustainability has emerged as a critical concern for international B2B buyers in the heavy rubber raincoat sector. As environmental awareness increases, businesses are prioritizing products that minimize ecological impact. Traditional manufacturing processes for rubber raincoats often involve harmful chemicals and non-biodegradable materials, raising ethical concerns. Consequently, buyers are seeking suppliers committed to sustainable practices, such as using natural rubber, recycled materials, and eco-friendly production techniques.

The importance of ethical supply chains cannot be overstated. Buyers are now more inclined to partner with manufacturers who demonstrate transparency in their sourcing practices. Certifications like Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 are becoming essential for verifying the environmental credentials of raincoat materials. These certifications not only reassure buyers about the sustainability of their products but also enhance brand reputation in a competitive marketplace.

Moreover, as consumers increasingly demand eco-friendly products, B2B buyers who prioritize sustainability can gain a significant market advantage. By sourcing heavy rubber raincoats that are ethically produced and environmentally friendly, businesses not only meet regulatory requirements but also align with the values of their end customers, fostering brand loyalty and trust.

What is the Brief Evolution of Heavy Rubber Raincoats in the B2B Context?

The heavy rubber raincoat has evolved significantly since its inception in the 19th century, transitioning from a niche historical garment to a vital piece of protective gear in various industries. Originally designed for the maritime sector, these coats were made from oilskin and rubberized fabrics to keep sailors dry. Over the decades, advancements in material technology and manufacturing processes have transformed heavy rubber raincoats into versatile products that cater to diverse applications.

In the modern B2B context, heavy rubber raincoats are no longer seen merely as protective clothing; they are regarded as essential equipment that enhances worker safety and productivity. The focus has shifted towards incorporating innovative features such as breathable fabrics, reinforced seams, and adjustable fits, allowing these garments to meet the rigorous demands of various industries, including construction, fishing, and outdoor recreation.

As the market continues to evolve, the fusion of historical design elements with contemporary functionality is setting the stage for the next generation of heavy rubber raincoats, ensuring they remain relevant and effective in protecting against the elements.

Frequently Asked Questions (FAQs) for B2B Buyers of heavy rubber raincoat

-

How do I choose the right heavy rubber raincoat for my business needs?

When selecting a heavy rubber raincoat, consider factors such as the intended use, climate conditions, and specific industry requirements. Assess the material’s durability, waterproof capabilities, and comfort features. Additionally, evaluate design elements like pockets, closures, and fit, which can influence usability. Request samples from suppliers to ensure the product meets your quality standards. Finally, consider the feedback from your team to ensure the raincoat aligns with their operational needs. -

What is the best material for heavy rubber raincoats in extreme weather?

For extreme weather conditions, look for raincoats made from high-quality PVC or rubberized fabric that offers superior waterproof and wind-resistant properties. These materials should also have reinforced seams to prevent leakage and ensure durability. Brands that incorporate breathable technology can enhance comfort during prolonged wear. Always verify the specifications with suppliers to ensure the material is suitable for your specific operational environment. -

What customization options are available for heavy rubber raincoats?

Customization options for heavy rubber raincoats often include color choices, branding (such as logos), and size adjustments. Some manufacturers may also offer features like detachable hoods, additional pockets, or reflective strips for safety. Discuss your specific requirements with potential suppliers to explore their customization capabilities, ensuring they can meet your branding and functionality needs. -

What are the typical minimum order quantities (MOQ) for heavy rubber raincoats?

Minimum order quantities for heavy rubber raincoats can vary significantly between suppliers, typically ranging from 100 to 500 units. Factors influencing MOQ include the manufacturer’s production capacity, material sourcing, and customization requests. When negotiating with suppliers, inquire about their flexibility on MOQs, especially if you are looking to start with a smaller order to test market demand. -

What payment terms should I expect when sourcing heavy rubber raincoats internationally?

Payment terms can vary by supplier and region but commonly include options like a deposit upfront (usually 30-50%) with the balance due before shipment. Some suppliers may offer net payment terms (e.g., net 30 or net 60 days) for established buyers. Always clarify payment methods accepted, including wire transfers, letters of credit, or online payment platforms, to ensure a smooth transaction. -

How can I ensure quality assurance when sourcing heavy rubber raincoats?

To ensure quality assurance, request samples before placing a large order. Establish clear quality standards with your supplier, including specifications for material, stitching, and waterproof testing. Consider implementing third-party inspections at the factory before shipment to verify compliance with your requirements. Additionally, review the supplier’s quality management certifications, such as ISO, to gauge their commitment to quality. -

What logistics considerations should I keep in mind when importing heavy rubber raincoats?

When importing heavy rubber raincoats, consider shipping methods, customs regulations, and potential tariffs. Evaluate logistics partners for reliability and experience in handling apparel shipments. Ensure you have all necessary documentation, including commercial invoices and packing lists, to facilitate customs clearance. Additionally, factor in lead times for production and shipping to align with your inventory needs. -

How can I vet suppliers for heavy rubber raincoats effectively?

To vet suppliers effectively, conduct thorough research, including checking their business licenses, certifications, and customer reviews. Request references from other clients, especially those in your industry. Utilize platforms like Alibaba or global trade forums to gauge supplier reputation. Additionally, consider visiting manufacturing facilities if possible, as this provides insights into their production capabilities and commitment to quality.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Heavy Rubber Raincoat Manufacturers & Suppliers List

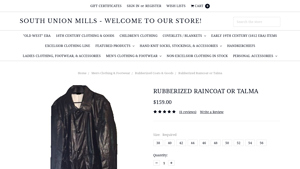

1. South Union Mills – Rubberized Raincoat

Domain: southunionmills.com

Registered: 2009 (16 years)

Introduction: Product Name: Rubberized Raincoat or Talma

Price: $159.00

SKU: Not specified

Sizes Available: 38, 40, 42, 44, 46, 48, 50, 52, 54, 56

Product Features:

– Authentic 19th Century Design: Modeled after original rubberized raincoats with a fold-down collar and two exterior patch pockets.

– Single-Breasted Closure: Classic design with a 4-button closure and hand-sewn buttonholes.

– Composite Buttons: Bl…

2. Carhartt – Heavy Duty Rain Gear

Domain: carhartt.com

Registered: 1996 (29 years)

Introduction: Heavy Duty Rain Gear from Carhartt, featuring a variety of options including insulated and unlined jackets and coats, lightweight rain gear, and accessories. The collection includes products designed for men, women, and kids, with options for plus sizes and various industries such as construction, farming, and medical. Key features include water protection, durability, and a range of styles suitab…

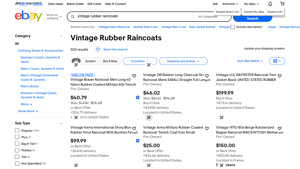

3. Blauer – Vintage Military Rubber Raincoat

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Vintage Rubber Raincoats available on eBay include various styles and conditions. Key products include: 1. Vintage Blauer Raincoat – Men Long 40 Nylon Rubber Coated Military 60s Trench, Pre-Owned, $40.79, delivery $37.20. 2. KLEPPER Vintage German Police Rubber Rain Coat Jacket, New (Other), $576.09, delivery $52.86. 3. Vintage U.S. RAYNSTER Raincoat Trench Jacket, Pre-Owned, $199.99, delivery $14…

4. Nasco – Heavy Duty Rain Coats

Domain: legionsafety.com

Registered: 2008 (17 years)

Introduction: Heavy Duty Rainwear includes various products such as Heavy Duty Rain Coats, Rain Jackets, Rain Pants, and Accessories. Key brands include Nasco and Tingley. Price ranges from $0.00 to $439.55. Arc flash ratings range from HRC 1 to HRC 2. Coat lengths available are Waist, Hip, Thigh, and Knee. High visibility options include ANSI Class 3 and enhanced visibility. Styles available are Men’s and Unis…

5. Waterproof Jacket – Best Options for Heavy Rain

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking for a solid waterproof jacket that can handle heavy rain for prolonged periods without soaking through. Price range is $150-$200 CAD. The jacket should breathe decently but prioritize keeping the torso completely dry in heavy rain. Intended use includes hiking, long walks (at least an hour from shelter), commuting, and occasional outdoor work. Important that pockets keep items like phone, …

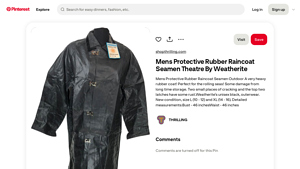

6. Weatherite – Mens Protective Rubber Raincoat

Domain: in.pinterest.com

Registered: 2009 (16 years)

Introduction: Mens Protective Rubber Raincoat Seamen Theatre By Weatherite, very heavy rubber coat, perfect for the rolling seas, some damage from long time storage including two small places of cracking and rust on the top two latches, unisex black outerwear, new condition, available sizes L (10 – 12) and XL (14 – 16), detailed measurements: Bust – 46 inches, Waist – 46 inches.

7. NYTimes – Unique Rubberized Coat

Domain: nytimes.com

Registered: 1994 (31 years)

Introduction: This company, NYTimes – Unique Rubberized Coat, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for heavy rubber raincoat

In the dynamic landscape of heavy rubber raincoat sourcing, international B2B buyers must prioritize quality, durability, and functionality. The historical craftsmanship seen in designs, such as those inspired by the 19th century, illustrates the enduring appeal of these garments. Modern iterations from leading manufacturers emphasize waterproof technologies and lightweight materials, catering to a variety of sectors including agriculture, fishing, and outdoor recreation.

Strategic sourcing not only ensures access to high-quality products but also fosters long-term partnerships with suppliers who understand the unique demands of diverse markets in Africa, South America, the Middle East, and Europe. Buyers should consider factors such as material performance, manufacturing standards, and supplier reliability when making purchasing decisions.

As climate challenges intensify, the demand for effective protective gear like heavy rubber raincoats will continue to grow. Now is the time for international buyers to leverage strategic sourcing practices to secure reliable supply chains. By investing in high-quality rain gear, businesses can enhance workforce safety and operational efficiency. Embrace the opportunity to connect with reputable suppliers and fortify your inventory against the elements. Your strategic sourcing journey starts today—explore the best options available in the market.