Introduction: Navigating the Global Market for pvc coated raincoat

In today’s rapidly changing climate, sourcing high-quality PVC coated raincoats presents a crucial challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe grapple with unpredictable weather patterns, the demand for durable, waterproof rainwear is at an all-time high. This comprehensive guide delves into the diverse types of PVC coated raincoats available in the market, exploring their specific applications across various sectors, from agriculture to construction.

Buyers will find invaluable insights into the latest trends in material technology, including the benefits of PVC’s waterproof properties and its adaptability in harsh environments. We will also provide actionable strategies for vetting suppliers, ensuring that you partner with manufacturers who meet stringent quality standards while offering competitive pricing.

By navigating the complexities of the global PVC coated raincoat market, this guide empowers B2B buyers to make informed purchasing decisions. Whether you’re operating in Vietnam, Brazil, or beyond, understanding the nuances of product specifications, cost considerations, and supplier reliability will enhance your procurement strategy and ultimately protect your workforce against the elements. Prepare to equip your team with the best rainwear solutions, ensuring safety and comfort in any weather condition.

Article Navigation

- Top 2 Pvc Coated Raincoat Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for pvc coated raincoat

- Understanding pvc coated raincoat Types and Variations

- Key Industrial Applications of pvc coated raincoat

- 3 Common User Pain Points for ‘pvc coated raincoat’ & Their Solutions

- Strategic Material Selection Guide for pvc coated raincoat

- In-depth Look: Manufacturing Processes and Quality Assurance for pvc coated raincoat

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘pvc coated raincoat’

- Comprehensive Cost and Pricing Analysis for pvc coated raincoat Sourcing

- Alternatives Analysis: Comparing pvc coated raincoat With Other Solutions

- Essential Technical Properties and Trade Terminology for pvc coated raincoat

- Navigating Market Dynamics and Sourcing Trends in the pvc coated raincoat Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pvc coated raincoat

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for pvc coated raincoat

Understanding pvc coated raincoat Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

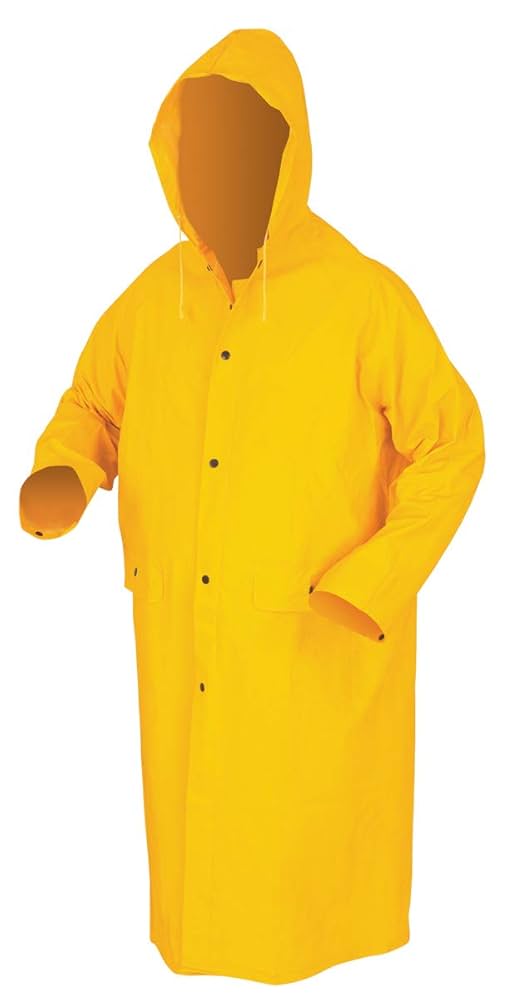

| Classic PVC Raincoat | Heavy-duty PVC material, detachable hood, snap front closure | Construction, environmental clean-up, fishing | Pros: Durable, waterproof, cost-effective. Cons: Limited breathability. |

| PVC/Polyester Blend Raincoat | Combination of PVC and polyester, enhanced durability | Industrial work, municipal services, agriculture | Pros: Lightweight, better breathability. Cons: Slightly higher cost. |

| Long PVC Raincoat | Extended length for maximum coverage, often 49 inches | Oil & gas industry, maritime operations | Pros: Excellent protection against heavy rain. Cons: Bulkier to store and transport. |

| Cape Vented PVC Raincoat | Cape vented back for airflow, snap closures | Hot climate outdoor work, waste management | Pros: Improved comfort in warm conditions. Cons: May allow some water ingress if not fitted properly. |

| Deluxe PVC Rain Jacket | Stylish design, varied color options, often with pockets | Retail, promotional events, outdoor activities | Pros: Versatile for casual use, appealing aesthetics. Cons: May not withstand extreme conditions. |

What are the Key Characteristics of Classic PVC Raincoats?

Classic PVC raincoats are constructed from a heavy-duty PVC material that ensures maximum waterproofing. They often feature practical elements such as a detachable hood and a snap front closure for easy wear. These raincoats are primarily used in industries like construction and environmental clean-up, where workers are exposed to wet conditions. Buyers should consider the durability and cost-effectiveness of these products, although it’s essential to note their limited breathability, which may be a drawback in warmer climates.

How Does a PVC/Polyester Blend Raincoat Enhance Durability?

PVC/polyester blend raincoats combine the waterproof qualities of PVC with the lightweight and breathable characteristics of polyester. This makes them suitable for a variety of applications, including industrial work and agricultural tasks. The blend offers improved comfort for the wearer, which can lead to increased productivity. However, the cost may be slightly higher than that of classic PVC options, which buyers should factor into their purchasing decisions.

Why Choose a Long PVC Raincoat for Heavy-Duty Applications?

Long PVC raincoats, typically around 49 inches in length, provide extensive coverage, making them ideal for industries such as oil and gas or maritime operations. Their design protects against heavy rain and splashes, ensuring that workers remain dry in challenging conditions. While they offer excellent protection, their bulkiness can pose storage and transportation challenges, which buyers should consider in relation to their operational needs.

What Advantages Does a Cape Vented PVC Raincoat Offer?

Cape vented PVC raincoats are designed with a cape vented back that allows for airflow, making them suitable for outdoor work in hot climates. This feature enhances comfort without compromising on waterproof capabilities, which is particularly valuable in waste management or similar sectors. However, buyers should ensure a proper fit to prevent potential water ingress, as the vented design may allow for some moisture entry.

What Makes a Deluxe PVC Rain Jacket Suitable for Retail?

Deluxe PVC rain jackets offer a stylish design and a variety of color options, making them appealing for retail and promotional events. They are versatile enough for casual use while still providing adequate waterproof protection for outdoor activities. However, buyers should be aware that these jackets may not withstand extreme weather conditions as effectively as more robust options, necessitating careful consideration of their intended application.

Key Industrial Applications of pvc coated raincoat

| Industry/Sector | Specific Application of PVC Coated Raincoat | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Site protection during adverse weather conditions | Ensures worker safety and productivity | Compliance with safety regulations, bulk purchasing discounts |

| Agriculture | Protection for farm workers during rain or wet conditions | Minimizes downtime and enhances worker comfort | Durability against chemicals, ease of movement |

| Maritime | Gear for fishermen and crew members on vessels | Prevents hypothermia and ensures safety on the water | Waterproof certification, availability in various sizes |

| Environmental Cleanup | Protective wear for workers handling hazardous materials | Reduces risk of contamination and health hazards | Chemical resistance, compliance with environmental regulations |

| Waste Management | Rain gear for workers collecting waste in wet conditions | Maintains hygiene and safety for waste handling staff | Easy to clean, resistant to wear and tear |

How is PVC Coated Raincoat Used in Construction?

In the construction industry, PVC coated raincoats are vital for ensuring worker safety during inclement weather. They are commonly worn by laborers on job sites to maintain visibility and protect against rain, thus minimizing the risk of slips and falls. For international buyers, especially in regions prone to heavy rainfall, sourcing durable and compliant raincoats is critical. It’s essential to consider features such as high visibility colors and compliance with local safety regulations to ensure worker safety and productivity.

What Role Does PVC Coated Raincoat Play in Agriculture?

Agricultural workers frequently face wet and muddy conditions, making PVC coated raincoats a practical solution for protecting them from the elements. These raincoats allow farmers to continue working efficiently during rain, which is crucial for tasks like harvesting or caring for livestock. Buyers in Africa and South America should prioritize sourcing raincoats that offer durability and comfort, as prolonged exposure to moisture can lead to health issues and decreased productivity.

How Do Maritime Workers Benefit from PVC Coated Raincoats?

In the maritime sector, PVC coated raincoats are essential for fishermen and crew members who work in wet and unpredictable environments. These raincoats provide a waterproof barrier that protects against heavy rain and splashes from waves, reducing the risk of hypothermia. For B2B buyers in the Middle East and Europe, sourcing high-quality rain gear that fits various body types is crucial, as it ensures comfort and safety while on deck.

Why are PVC Coated Raincoats Important for Environmental Cleanup?

During environmental cleanup operations, workers often encounter hazardous materials that require protective clothing. PVC coated raincoats serve as a barrier against moisture and contaminants, ensuring that workers remain safe while performing their duties. Buyers should focus on sourcing raincoats that meet stringent chemical resistance standards, particularly when operating in regions with strict environmental regulations, to mitigate health risks.

How Do Waste Management Workers Utilize PVC Coated Raincoats?

In the waste management industry, workers are frequently exposed to wet conditions while collecting refuse. PVC coated raincoats help maintain hygiene and safety by keeping employees dry and reducing the risk of exposure to unsanitary conditions. For international buyers, it’s important to consider the ease of cleaning and durability of the raincoats to ensure they withstand the rigors of daily use in tough environments.

3 Common User Pain Points for ‘pvc coated raincoat’ & Their Solutions

Scenario 1: Sourcing High-Quality PVC Coated Raincoats for Harsh Environments

The Problem: B2B buyers in industries like construction, fishing, or agriculture often struggle to find PVC coated raincoats that can withstand extreme weather conditions. Many suppliers offer low-quality products that fail to provide adequate waterproofing or durability, leading to employee dissatisfaction and increased costs due to frequent replacements. This is especially critical in regions with heavy rainfall or adverse weather, where the risk of accidents and productivity loss rises significantly.

The Solution: To address this challenge, buyers should prioritize sourcing from reputable manufacturers known for high-quality PVC rainwear. Conduct thorough research on suppliers, checking their certifications, customer reviews, and product specifications. Look for PVC coated raincoats that feature reinforced seams, adjustable hoods, and a thickness of at least 0.35mm, which indicates better durability. Establishing long-term relationships with suppliers who understand the regional climate challenges can also lead to customized solutions that meet specific industry needs, ensuring reliable protection for workers.

Scenario 2: Balancing Cost and Quality in Bulk Purchases of PVC Coated Raincoats

The Problem: Many B2B buyers face the dilemma of balancing cost and quality when purchasing PVC coated raincoats in bulk. Opting for the cheapest option often results in subpar products that don’t meet safety standards, while high-quality alternatives may strain budgets. This can be particularly concerning for companies operating in developing regions where budget constraints are prevalent, yet the need for reliable protective gear remains critical.

The Solution: Buyers can mitigate this issue by employing a cost-benefit analysis approach. Start by identifying the total cost of ownership, which includes purchase price, durability, maintenance, and potential replacement costs. Engage with suppliers to negotiate bulk purchase discounts while ensuring that quality isn’t compromised. Request samples to evaluate the product’s performance in real-world conditions before committing to a large order. Additionally, consider exploring local manufacturers who may offer competitive pricing without sacrificing quality, thus supporting local economies.

Scenario 3: Ensuring Comfort and Usability in PVC Coated Raincoats for Workers

The Problem: Comfort and usability are often overlooked when selecting PVC coated raincoats, leading to decreased worker productivity and morale. Heavy, non-breathable materials can cause discomfort, especially in warmer climates, while features like poor fit or lack of adjustability can hinder mobility. B2B buyers must ensure that the raincoats are not only protective but also functional for the tasks at hand.

The Solution: Buyers should look for PVC raincoats that incorporate ergonomic designs and ventilation features, such as underarm vents or mesh linings, to enhance breathability. It’s essential to involve end-users in the selection process to gather feedback on fit and comfort. Offering a variety of sizes and styles can also help accommodate different body types and work activities. Additionally, training workers on how to properly wear and adjust their raincoats can improve comfort and effectiveness, ultimately leading to higher productivity levels and better safety outcomes.

Strategic Material Selection Guide for pvc coated raincoat

What Are the Key Materials Used in PVC Coated Raincoats?

When selecting materials for PVC coated raincoats, several options are commonly considered, each with distinct properties, advantages, and disadvantages. Understanding these materials will help B2B buyers make informed decisions that align with their operational needs and market demands.

What Are the Key Properties of PVC in Raincoat Manufacturing?

PVC (Polyvinyl Chloride) is the most prevalent material used in raincoat production due to its waterproof properties and durability. It offers excellent resistance to moisture, making it ideal for outdoor applications. PVC raincoats can withstand a wide range of temperatures, typically from -20°C to 60°C, and can endure various weather conditions without degrading. However, PVC is not breathable, which may lead to discomfort in warmer climates.

Pros: PVC raincoats are cost-effective, highly durable, and resistant to water and chemicals. They are suitable for heavy-duty applications, particularly in industries like construction and agriculture.

Cons: The lack of breathability can be a significant drawback, particularly in humid environments. Additionally, PVC can become rigid in colder temperatures, potentially limiting mobility.

How Does Polyester Enhance PVC Raincoats?

Polyester is often combined with PVC to enhance the material’s overall performance. This blend not only retains the waterproof characteristics of PVC but also adds durability and flexibility. Polyester’s strength allows for a thinner material that still meets performance standards, making it suitable for a wider range of applications.

Pros: The combination of polyester with PVC results in a lightweight, flexible raincoat that maintains waterproof capabilities. This blend can also improve comfort, making it more suitable for prolonged wear.

Cons: While this combination enhances performance, it may increase production costs slightly compared to pure PVC. Additionally, the manufacturing process can be more complex, requiring specialized equipment.

What Are the Benefits of Using a PVC/Polyester Blend?

A PVC/polyester blend typically features a thickness of around 0.35mm, making it a popular choice in the industry. This material not only retains the waterproof and chemical-resistant properties of PVC but also offers enhanced breathability and comfort, which is crucial for users in warmer regions.

Pros: The blend provides a good balance between durability and comfort, making it suitable for various applications, including environmental clean-ups and outdoor work.

Cons: The increased complexity in manufacturing can lead to higher costs. Additionally, while the breathability is improved, it may still not meet the standards required for extreme heat applications.

What Compliance Standards Should International Buyers Consider?

When sourcing PVC coated raincoats, international buyers should be aware of compliance standards that vary by region. For instance, ASTM standards are prevalent in the U.S., while European markets may require compliance with EN standards. In South America and Africa, local regulations may dictate specific material requirements and safety certifications.

Pros: Understanding these standards can help buyers ensure that their products meet local regulations, thus avoiding potential legal issues and enhancing marketability.

Cons: Navigating these compliance requirements can be complex and may require additional resources for testing and certification, potentially increasing costs.

Summary Table of Material Options for PVC Coated Raincoats

| Material | Typical Use Case for pvc coated raincoat | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Heavy-duty outdoor work | Highly durable and waterproof | Not breathable; can be rigid in cold weather | Low |

| Polyester | General outdoor use | Lightweight and flexible | Slightly higher production costs | Medium |

| PVC/Polyester Blend | Environmental clean-ups | Good balance of comfort and durability | Increased manufacturing complexity | Medium |

| PVC with Compliance Standards | Industrial applications | Meets local regulations for safety and quality | Complexity in navigating compliance | Medium |

This strategic material selection guide provides a comprehensive overview for B2B buyers considering PVC coated raincoats, ensuring they choose the right material for their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for pvc coated raincoat

What Are the Main Stages in the Manufacturing Process of PVC Coated Raincoats?

The manufacturing process of PVC coated raincoats involves several critical stages, ensuring that the end product meets the necessary durability and waterproof standards. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in manufacturing PVC coated raincoats is material preparation. This involves sourcing high-quality PVC (polyvinyl chloride) and potentially polyester or other backing materials. Suppliers often conduct a thorough vetting process to ensure that the materials comply with international standards. This is particularly crucial for international B2B buyers who may have specific requirements regarding material properties such as thickness, flexibility, and resistance to environmental conditions.

Forming

Once the materials are prepared, they undergo the forming process. This typically involves cutting the PVC into specific patterns that correspond to the design of the raincoat. Advanced cutting techniques such as die-cutting or laser cutting are often employed to ensure precision. In some facilities, automated cutting machines are used to enhance efficiency and reduce waste, which is a critical consideration for cost-effective production.

Assembly

The assembly stage involves stitching or welding the cut pieces together. High-frequency welding is commonly used for PVC raincoats, creating strong, waterproof seams. Some manufacturers may also use heat sealing techniques to enhance the waterproofing of seams. Quality control checks at this stage are essential to identify any flaws in stitching or alignment, ensuring that the final product is both functional and aesthetically pleasing.

Finishing

The final stage, finishing, involves adding features such as hoods, snaps, and pockets, as well as performing any necessary waterproofing treatments. This may include applying additional PVC coatings or treatments that enhance the coat’s durability and resistance to chemicals. Aesthetic elements, such as color application or branding, may also be completed at this stage.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is a vital aspect of the manufacturing process, particularly for products like PVC coated raincoats that require stringent performance specifications. The QA process typically adheres to international standards such as ISO 9001, as well as industry-specific certifications like CE marking for compliance with European safety standards.

What Are the Relevant International and Industry-Specific Standards?

Internationally recognized standards such as ISO 9001 focus on quality management systems and continuous improvement processes. For PVC raincoats, compliance with CE marking indicates adherence to safety and environmental protection standards within the European market. In addition, buyers should be aware of specific certifications relevant to their region, such as API standards in the oil and gas industry, which may require specialized protective gear.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are crucial in ensuring that each stage of production meets the required standards. Typically, these checkpoints include:

-

Incoming Quality Control (IQC): This initial inspection verifies the quality of raw materials before they enter the manufacturing process. Suppliers should provide documentation of material specifications and test results to confirm compliance.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC involves regular inspections to monitor the quality of assembly and forming processes. This may include visual inspections for defects and measurements of seam integrity.

-

Final Quality Control (FQC): The final inspection occurs after the raincoat is fully assembled and finished. This involves rigorous testing of the product’s waterproof capabilities, seam strength, and overall appearance. Common testing methods may include water resistance tests, tensile strength tests, and visual inspections for any manufacturing defects.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, ensuring supplier quality control is paramount. Here are effective strategies to verify supplier practices:

-

Conduct Audits: Regular audits of suppliers can help verify compliance with quality standards. This can include on-site inspections of manufacturing facilities and processes.

-

Request Quality Reports: Buyers should ask suppliers for detailed quality assurance reports that outline testing results, compliance with international standards, and any corrective actions taken for non-conformance.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can occur at various stages of production, offering an additional layer of assurance.

-

Certification Verification: Buyers should verify any certifications claimed by suppliers to ensure they are current and relevant. This may involve checking with certifying bodies or industry associations.

What Are the QC and Certification Nuances for International B2B Buyers?

Navigating the complexities of quality control and certification can be challenging for international buyers, especially in regions such as Africa, South America, the Middle East, and Europe. Each market may have different requirements and standards, so it is essential for buyers to be informed about:

-

Regional Standards: Understand the specific standards applicable to your target market. For example, certain countries may have stricter chemical safety regulations that affect material choice.

-

Import Regulations: Familiarize yourself with import regulations in your region, which may require specific documentation or certifications for compliance.

-

Cultural Considerations: Be aware of cultural differences that may influence business practices and expectations regarding quality. Building strong relationships with suppliers can facilitate better communication and compliance.

In summary, understanding the manufacturing processes and quality assurance practices for PVC coated raincoats is essential for B2B buyers. By prioritizing quality and compliance, businesses can ensure they source reliable, durable products that meet the demands of their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pvc coated raincoat’

The following guide provides a structured approach for B2B buyers seeking to procure PVC-coated raincoats. This checklist will help ensure that you make informed decisions, secure quality products, and establish reliable supplier relationships.

Step 1: Define Your Technical Specifications

Start by determining the specific requirements for the PVC-coated raincoats you need. Consider factors such as material thickness (e.g., 0.35mm or thicker for durability), waterproofing capabilities, and any additional features like detachable hoods or chemical resistance. Clearly outlined specifications will help streamline the sourcing process and ensure that the products meet your operational needs.

Step 2: Identify Your Target Market and Use Cases

Understanding the target market and intended use of the raincoats is essential. Are they for industrial use, outdoor recreation, or emergency services? Different applications may require varying levels of durability, visibility (e.g., high-visibility colors for safety), and comfort. This insight will guide you in selecting the right features and styles that align with your buyers’ needs.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure they can meet your quality and delivery expectations. Request company profiles, product samples, and references from other clients in similar industries. Look for suppliers with a proven track record in producing PVC-coated rainwear, especially those who can provide certifications related to material quality and safety standards.

- Check for certifications: Verify that the supplier meets international standards (e.g., ISO, ASTM) for rainwear.

- Assess production capacity: Ensure they can handle your order volume and timelines.

Step 4: Request and Analyze Samples

Before placing a bulk order, request samples of the raincoats to evaluate their quality firsthand. Assess factors such as waterproofing effectiveness, comfort, and overall construction quality. This step is vital for confirming that the products align with your specifications and expectations.

- Conduct stress tests: Check for durability under various conditions to ensure the raincoats will withstand intended use.

- Gather feedback: If possible, involve end-users in the evaluation process to get practical insights.

Step 5: Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations to establish favorable terms. Discuss pricing, payment terms, lead times, and return policies. Clear agreements help prevent misunderstandings and ensure a smooth procurement process.

- Consider volume discounts: Inquire about pricing structures based on order size to optimize your budget.

- Clarify shipping terms: Understand who bears shipping costs and how delays will be managed.

Step 6: Ensure Compliance with Local Regulations

Different regions may have specific regulations regarding safety and quality standards for protective clothing. Ensure that the raincoats comply with local laws in your target markets, especially if you are sourcing from international suppliers. This step is crucial to avoid legal issues and ensure product acceptance.

- Research import regulations: Understand any tariffs or import duties that may apply to your order.

- Confirm documentation: Ensure the supplier provides necessary compliance documents for customs clearance.

Step 7: Establish a Quality Control Process

Implement a quality control process to monitor the products during production and upon delivery. This can include regular inspections, testing of random samples, and establishing key performance indicators (KPIs) for quality assurance. A solid QC process helps maintain product consistency and reduces the risk of defects.

- Schedule inspections: Consider third-party inspections for larger orders to ensure compliance with your quality standards.

- Document findings: Keep records of inspections and any issues encountered for future reference.

Following this checklist will enhance your procurement strategy for PVC-coated raincoats, ensuring you secure high-quality products that meet your business needs while establishing strong supplier relationships.

Comprehensive Cost and Pricing Analysis for pvc coated raincoat Sourcing

What Are the Key Cost Components for PVC Coated Raincoat Sourcing?

When sourcing PVC coated raincoats, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The principal material used in PVC raincoats is PVC itself, which varies in thickness and quality. High-quality PVC can significantly increase production costs but offers better durability and waterproof capabilities. Additionally, some raincoats incorporate polyester blends, which can enhance comfort and breathability, impacting the overall price.

-

Labor: Labor costs are influenced by the manufacturing location. Regions with lower wage standards, such as parts of Southeast Asia, may offer cheaper labor, which can reduce the overall cost. However, countries with stringent labor laws and higher wages may reflect this in higher product prices.

-

Manufacturing Overhead: This includes costs related to the operation of production facilities, utilities, and maintenance. Efficient manufacturing processes can mitigate these costs, making it vital for suppliers to demonstrate their operational efficiencies.

-

Tooling: Custom designs or specifications may require specialized tooling, which can lead to increased initial costs. Buyers should consider whether they require customization, as this can significantly affect the price.

-

Quality Control (QC): Ensuring that raincoats meet specific quality standards involves costs associated with testing and inspections. Certifications for quality and safety can also add to the pricing, especially if the product is intended for markets with strict compliance regulations.

-

Logistics: Transportation and shipping costs can vary widely based on the origin of the goods and the chosen Incoterms. For international buyers, understanding these logistics costs is essential, as they can significantly impact the total cost.

-

Margin: Supplier margins will vary based on the competitive landscape and the perceived value of the raincoats. Buyers should be aware that higher margins might correlate with higher-quality products or brands with established reputations.

How Do Price Influencers Affect PVC Coated Raincoat Costs?

Several factors influence the pricing of PVC coated raincoats, which can vary significantly based on the buyer’s requirements and market conditions.

-

Volume and Minimum Order Quantities (MOQ): Larger orders often lead to lower per-unit prices. Suppliers may offer discounts for bulk purchases, which can be an essential consideration for businesses looking to maximize cost efficiency.

-

Specifications and Customization: Custom features, such as additional pockets, detachable hoods, or specific color requirements, will increase costs. Buyers should assess whether these customizations are necessary for their target market.

-

Quality and Certifications: Products with certifications for safety and environmental compliance often come at a premium. Buyers should evaluate the necessity of these certifications based on their market requirements.

-

Supplier Factors: The reputation, location, and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record and quality assurance processes.

-

Incoterms: The chosen Incoterms can influence the total landed cost of the product. Buyers should clarify responsibilities for shipping and duties to avoid unexpected expenses.

What Are the Best Buyer Tips for Sourcing PVC Coated Raincoats?

For international B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe, several strategies can enhance procurement efficiency.

-

Negotiation: Engage in negotiations with suppliers to secure better pricing, especially for larger orders. Understanding the cost components can provide leverage during discussions.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, shipping, and potential warranty claims. A lower purchase price does not always equate to lower overall costs.

-

International Pricing Nuances: Be aware of currency fluctuations and their impact on pricing. Establishing contracts in stable currencies can mitigate risks associated with exchange rates.

-

Supplier Evaluation: Conduct thorough evaluations of potential suppliers, including their production capabilities, past performance, and reliability. This due diligence can prevent costly mistakes.

-

Market Trends: Stay informed about market trends and technological advancements in raincoat materials. Innovations may lead to better pricing or features that can be advantageous in competitive markets.

By understanding these cost structures and pricing influencers, B2B buyers can make informed decisions that align with their operational needs and market demands.

Alternatives Analysis: Comparing pvc coated raincoat With Other Solutions

Exploring Alternative Solutions to PVC Coated Raincoats

When it comes to protective rainwear, businesses often seek the most effective and economical solutions to meet their specific needs. PVC coated raincoats are popular due to their durability and waterproof capabilities, but several alternative solutions can also provide effective protection against the elements. This section compares PVC coated raincoats with two viable alternatives: polyurethane rainwear and breathable waterproof jackets.

| Comparison Aspect | PVC Coated Raincoat | Polyurethane Rainwear | Breathable Waterproof Jacket |

|---|---|---|---|

| Performance | Excellent waterproofing; less breathable | Good waterproofing; moderate breathability | Superior breathability; good waterproofing |

| Cost | Generally low-cost ($12 – $165) | Moderate cost ($30 – $150) | Higher cost ($50 – $300) |

| Ease of Implementation | Ready-to-wear; minimal setup required | Ready-to-wear; minimal setup required | Requires proper sizing and layering |

| Maintenance | Easy to clean; limited longevity | Easy to clean; moderate longevity | Requires careful washing; can be damaged by harsh detergents |

| Best Use Case | Heavy-duty work environments; construction, fishing | General outdoor activities; light industrial use | Active outdoor sports; hiking, camping |

What Are the Pros and Cons of Polyurethane Rainwear?

Polyurethane (PU) rainwear is an alternative that offers good waterproofing along with improved breathability compared to PVC. This material is lighter and more flexible, making it suitable for a range of outdoor activities. However, PU rainwear can be more expensive and may not provide the same level of durability in extreme conditions as PVC. Businesses looking for a balance between comfort and protection during moderate weather conditions may find PU rainwear a favorable option.

What Are the Advantages and Disadvantages of Breathable Waterproof Jackets?

Breathable waterproof jackets, often made from advanced synthetic materials, provide excellent moisture management and comfort for the wearer. They are designed for active use, allowing sweat to escape while keeping rain out. However, they tend to come at a higher price point and may require more careful maintenance to preserve their waterproof qualities. For businesses focused on outdoor activities that demand high mobility and comfort, breathable jackets are an ideal choice, although they may not be as rugged as PVC options.

How to Choose the Right Solution for Your Needs

Selecting the appropriate rainwear solution hinges on understanding the specific requirements of your business and the conditions in which the gear will be used. For industries like construction and fishing, where heavy-duty protection is paramount, PVC coated raincoats provide unmatched durability and affordability. On the other hand, for outdoor enthusiasts engaged in activities that require high mobility and comfort, breathable waterproof jackets might be the better choice despite their higher cost. Polyurethane rainwear serves as a middle ground, offering a balance of features that may suit various applications. By assessing the performance, cost, and maintenance needs of each option, B2B buyers can make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for pvc coated raincoat

What Are the Key Technical Properties of PVC Coated Raincoats?

When sourcing PVC coated raincoats for commercial purposes, understanding their technical properties is essential for ensuring quality and suitability for specific applications. Here are critical specifications to consider:

-

Material Composition

PVC (Polyvinyl Chloride) is the primary material used in these raincoats, known for its waterproof properties and durability. Many raincoats incorporate a polyester backing, enhancing strength and comfort. This combination provides resistance against wear and tear, making it ideal for industries such as construction and agriculture where exposure to harsh weather is common. -

Thickness

The thickness of the PVC layer, typically measured in millimeters (mm), is crucial for defining the coat’s durability and waterproof effectiveness. For instance, a thickness of 0.35 mm is standard for many commercial-grade raincoats, offering a balance between flexibility and sturdiness. A thicker material may be more durable but can also be less comfortable in warmer conditions. -

Waterproof Rating

This specification indicates the level of water resistance the raincoat offers. A higher waterproof rating means the raincoat can withstand heavier rainfall without leaking. For B2B buyers, this rating is vital as it directly affects the performance of the garment in critical environments, ensuring that workers remain dry and protected. -

Chemical Resistance

Many PVC coated raincoats are designed to be chemically resistant, making them suitable for environments where exposure to hazardous substances is a concern. This property is particularly relevant for industries such as oil and gas or chemical manufacturing, where personal protective equipment (PPE) must withstand corrosive materials. -

Breathability

While PVC is inherently waterproof, it can be less breathable compared to other materials. Some advanced PVC raincoats are designed with ventilation features to allow moisture vapor to escape, enhancing wearer comfort in hot, humid conditions. This is essential for B2B buyers looking for rainwear that balances protection with comfort. -

Size and Fit

Sizing options can range from small to 5XL or more, with features like adjustable cuffs and hoods for a customizable fit. Ensuring the right fit is critical for maximizing protection and comfort, especially in a work setting where mobility is necessary.

Which Trade Terms Are Commonly Used in the PVC Raincoat Industry?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several commonly used terms:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of PVC raincoats, OEMs often provide custom-branded products for larger retailers, allowing businesses to offer unique rainwear without manufacturing it themselves. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. For PVC coated raincoats, suppliers may set an MOQ to ensure production efficiency. Understanding MOQ is essential for B2B buyers to manage inventory costs effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and availability for specific products. B2B buyers should prepare detailed RFQs that include specifications, quantities, and delivery timelines to receive accurate quotes for PVC raincoats. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international contracts to define the responsibilities of buyers and sellers. Understanding Incoterms is crucial for B2B transactions involving PVC raincoats, as they determine who is responsible for shipping, insurance, and tariffs. -

Lead Time

Lead time refers to the time it takes from placing an order until it is received. This is particularly important in the raincoat industry, where seasonal demands may require timely deliveries to ensure stock levels meet customer needs. -

Customs Duties

These are tariffs imposed on imported goods, which can significantly affect the overall cost of PVC raincoats. B2B buyers must be aware of potential customs duties when sourcing products internationally to accurately calculate total expenses.

By familiarizing themselves with these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing PVC coated raincoats, ensuring they meet both quality standards and market demands.

Navigating Market Dynamics and Sourcing Trends in the pvc coated raincoat Sector

What Are the Key Market Trends Influencing the PVC Coated Raincoat Sector?

The PVC coated raincoat market is currently experiencing robust growth driven by several global factors. Increased awareness of climate change and unpredictable weather patterns has led to a heightened demand for reliable waterproof clothing across various industries, including agriculture, construction, and outdoor recreation. This demand is particularly strong in regions like Africa and South America, where seasonal rains can disrupt daily activities and economic operations.

Emerging B2B technology trends are reshaping sourcing strategies in this sector. Digital platforms and e-commerce solutions are facilitating easier access to suppliers, enabling international buyers to source high-quality PVC raincoats at competitive prices. Additionally, advancements in materials science are leading to the development of lighter, more durable PVC fabrics that offer improved comfort without sacrificing waterproof capabilities. For instance, hybrid materials combining PVC with polyester are becoming increasingly popular, as they provide enhanced breathability and flexibility, addressing the discomfort often associated with traditional PVC garments.

Market dynamics are also shifting towards customization and branding. Buyers are increasingly seeking options that allow for personalized designs and logos, particularly in industries such as hospitality and corporate events where brand visibility is key. As a result, manufacturers are adapting their offerings to include customizable rainwear, which can attract a broader customer base.

How Is Sustainability and Ethical Sourcing Shaping the PVC Coated Raincoat Industry?

Sustainability is becoming a pivotal consideration for B2B buyers in the PVC coated raincoat sector. The environmental impact of PVC production and disposal has prompted many companies to seek greener alternatives. Buyers are now prioritizing suppliers who adopt sustainable practices, such as using recycled PVC or developing biodegradable materials.

Ethical sourcing is equally important, as buyers are increasingly concerned about the labor practices within the supply chain. Companies that can demonstrate compliance with ethical labor standards are likely to gain a competitive edge. Certifications such as OEKO-TEX and GOTS (Global Organic Textile Standard) are becoming vital for suppliers aiming to appeal to environmentally conscious buyers.

Moreover, the integration of sustainability into product development is influencing design choices. Manufacturers are exploring eco-friendly dyes and non-toxic additives to reduce the ecological footprint of their products. By prioritizing these green certifications and sustainable materials, B2B buyers can ensure that their sourcing aligns with corporate social responsibility goals and the growing consumer demand for environmentally friendly products.

What Is the Historical Context Behind PVC Coated Raincoats in B2B Markets?

The evolution of PVC coated raincoats can be traced back to the early 20th century when advancements in synthetic materials began to revolutionize the textile industry. Initially developed for industrial use, PVC rainwear was valued for its durability and waterproof properties, making it an essential garment for workers in agriculture, fishing, and construction.

Over the decades, as technology advanced, the production processes became more refined, leading to the creation of lighter and more comfortable rainwear options. The introduction of PVC blends with other materials, such as polyester, has not only enhanced functionality but has also allowed for greater design versatility. Today, PVC coated raincoats are not just practical tools for weather protection; they have evolved into fashionable and customizable items, catering to diverse market needs across various sectors globally.

This historical perspective highlights the adaptability of PVC raincoat manufacturing in response to changing market demands, setting the stage for future innovations and trends in the industry.

Frequently Asked Questions (FAQs) for B2B Buyers of pvc coated raincoat

-

1. How do I choose the right PVC coated raincoat for my business needs?

Selecting the appropriate PVC coated raincoat involves assessing your specific requirements, such as the intended use, climate conditions, and the level of durability needed. Consider factors like the coat’s thickness, waterproofing capabilities, and additional features like detachable hoods or ventilation systems. For industries like construction or agriculture, look for options that comply with safety standards and provide adequate protection against chemicals or heavy rain. It’s also beneficial to request samples from suppliers to evaluate the quality before placing a bulk order. -

2. What are the key features to look for in a high-quality PVC coated raincoat?

When sourcing PVC coated raincoats, prioritize features such as waterproofing, durability, and comfort. Look for products made from high-quality PVC with a polyester backing for added strength. Essential features include a detachable hood, adjustable cuffs, and reinforced seams to prevent leaks. Additionally, consider the coat’s weight and breathability if it will be worn for extended periods, especially in warmer climates. Compliance with safety standards is also crucial to ensure worker protection. -

3. What is the minimum order quantity (MOQ) for PVC coated raincoats?

MOQs for PVC coated raincoats vary significantly by supplier and can range from as low as 50 units to several hundred. It is essential to confirm the MOQ with potential suppliers during the negotiation process. Some manufacturers may offer flexibility in MOQs for first-time buyers or bulk orders. Understanding the MOQ can help you plan your inventory and budget effectively, ensuring you meet both your operational needs and cost constraints. -

4. How can I vet suppliers of PVC coated raincoats for quality and reliability?

To vet suppliers, start by researching their reputation through online reviews, industry forums, and trade associations. Request references from other clients and inquire about their manufacturing processes and quality control measures. It’s also advisable to verify their certifications, such as ISO or compliance with local safety regulations. Consider conducting a factory visit or requesting product samples to assess the quality of their raincoats firsthand before making a purchasing decision. -

5. What payment terms should I expect when ordering PVC coated raincoats internationally?

Payment terms for international orders can vary, but common practices include a deposit (typically 30-50%) upfront, with the balance due before shipping. Some suppliers may offer net payment terms, allowing payment within a specified period post-delivery. Always clarify payment methods accepted (e.g., bank transfers, letters of credit) and ensure that the terms are documented in your purchase agreement. Negotiating favorable terms can improve your cash flow and reduce risk in international transactions. -

6. What logistics considerations should I keep in mind when importing PVC coated raincoats?

When importing PVC coated raincoats, consider shipping methods, customs clearance, and associated duties or taxes. Choose between air freight for speed or sea freight for cost-effectiveness, depending on your timeline and budget. Engage a reputable freight forwarder to navigate logistics and ensure compliance with import regulations in your country. It’s also wise to factor in lead times for production and shipping to avoid delays in your supply chain. -

7. Are there customization options available for PVC coated raincoats?

Many manufacturers offer customization options for PVC coated raincoats, allowing you to add features like specific colors, sizes, or branding elements such as logos. Custom orders may require larger MOQs or longer lead times, so it’s essential to discuss these options early in the negotiation process. Ensure that you provide clear specifications and request samples of any customized features to ensure they meet your expectations before finalizing the order. -

8. How can I ensure quality assurance for my bulk order of PVC coated raincoats?

To ensure quality assurance, establish clear specifications and standards with your supplier before production begins. Request regular updates and quality checks during the manufacturing process, and consider hiring a third-party inspection service to evaluate the products before shipment. Additionally, having a clear return policy and warranty terms can protect your investment and ensure you receive raincoats that meet your quality expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 2 Pvc Coated Raincoat Manufacturers & Suppliers List

1. Carhartt – PVC Waterproof Raincoats

2. PVC Raincoats for Women – Various Colors & Sizes

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: PVC Raincoats for Women available in various colors including Blue, Red, Green, Pink, and Purple. Brands include Unbranded, Misty Harbor, and Totes. Sizes range from XS to 3X, with options for hooded designs, lined interiors, and various styles such as long raincoats and slickers. Prices range from approximately $14.99 to $225.00, with shipping costs varying by seller.

Strategic Sourcing Conclusion and Outlook for pvc coated raincoat

The strategic sourcing of PVC-coated raincoats presents a significant opportunity for international buyers looking to enhance their procurement strategies. As demonstrated by leading manufacturers, these raincoats offer unparalleled waterproof protection, essential for various industries including construction, agriculture, and outdoor recreation. The durability and weather-resistant properties of PVC make it a preferred choice, ensuring that your workforce remains protected in challenging conditions.

By leveraging strategic sourcing, businesses can secure high-quality rainwear at competitive prices while also ensuring compliance with safety regulations. This approach not only optimizes supply chains but also fosters long-term relationships with reliable suppliers across Africa, South America, the Middle East, and Europe.

Looking ahead, the demand for PVC-coated raincoats is expected to grow, driven by increasing awareness of worker safety and environmental conditions. We encourage B2B buyers to actively explore partnerships with reputable suppliers to capitalize on this trend. Investing in quality rainwear today will not only safeguard your employees but also enhance operational efficiency in the face of unpredictable weather patterns. Embrace this opportunity to strengthen your sourcing strategy and ensure that your business is equipped to handle the elements with confidence.