Introduction: Navigating the Global Market for sublimated rain jacket

Navigating the complexities of sourcing high-quality sublimated rain jackets can be a daunting challenge for international B2B buyers. With diverse markets across Africa, South America, the Middle East, and Europe, understanding regional preferences, material quality, and customization options is essential to meet customer demands. This guide is designed to empower you with the knowledge needed to make informed purchasing decisions. We will explore the various types of sublimated rain jackets available, their applications in different industries, and essential factors to consider when vetting suppliers.

Moreover, we will delve into pricing structures and lead times, ensuring you are equipped to negotiate effectively and manage expectations. By focusing on the unique needs of each market—whether it’s the vibrant colors favored in South America or the functional designs sought in Europe—this guide aims to enhance your sourcing strategy.

With insights into the sublimation process and the latest trends in rain jacket customization, you will gain a competitive edge in delivering stylish and functional products to your clientele. Whether you are looking to cater to the outdoor adventure segment or corporate branding opportunities, understanding the nuances of the sublimated rain jacket market will position your business for success in a global landscape.

Article Navigation

- Top 6 Sublimated Rain Jacket Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for sublimated rain jacket

- Understanding sublimated rain jacket Types and Variations

- Key Industrial Applications of sublimated rain jacket

- 3 Common User Pain Points for ‘sublimated rain jacket’ & Their Solutions

- Strategic Material Selection Guide for sublimated rain jacket

- In-depth Look: Manufacturing Processes and Quality Assurance for sublimated rain jacket

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘sublimated rain jacket’

- Comprehensive Cost and Pricing Analysis for sublimated rain jacket Sourcing

- Alternatives Analysis: Comparing sublimated rain jacket With Other Solutions

- Essential Technical Properties and Trade Terminology for sublimated rain jacket

- Navigating Market Dynamics and Sourcing Trends in the sublimated rain jacket Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of sublimated rain jacket

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for sublimated rain jacket

Understanding sublimated rain jacket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fully Customizable Jacket | Any color, print, and design; mesh lining | Corporate branding, promotional events | Pros: Complete design freedom; unique branding. Cons: Longer lead times, typically 30 days. |

| Lightweight Waterproof Jacket | Lightweight materials; breathable; often compact | Outdoor events, sports teams | Pros: Easy to carry; ideal for active use. Cons: May lack insulation for colder climates. |

| Anorak Style Rain Jacket | Half-zip design; hidden pockets; casual fit | Casual wear, team uniforms | Pros: Stylish; versatile for various activities. Cons: Limited size options; may not suit all professional settings. |

| Performance Layered Jacket | Multi-layer construction; enhanced insulation and breathability | Extreme weather conditions, outdoor adventures | Pros: Excellent protection; durable. Cons: Higher cost; may be overbuilt for mild weather. |

| Sublimated Warmup Jacket | Soft interior; customizable with team logos; relaxed fit | Sports teams, cheerleading, promotional events | Pros: Comfortable; stylish for team representation. Cons: May require minimum order quantities. |

What Are the Characteristics of Fully Customizable Sublimated Rain Jackets?

Fully customizable sublimated rain jackets offer businesses the flexibility to incorporate any color, print, or design, making them ideal for corporate branding and promotional events. These jackets typically feature a mesh lining for comfort and breathability. B2B buyers should consider the longer lead time of approximately 30 days from proof approval when planning orders, as this can impact event timelines. The ability to create a unique product aligns well with brand identity, but the custom nature can also lead to higher costs.

How Do Lightweight Waterproof Jackets Benefit B2B Buyers?

Lightweight waterproof jackets are designed for breathability and ease of movement, making them suitable for outdoor events and sports teams. They are compact and easy to carry, which is advantageous for businesses needing to transport gear frequently. However, buyers should note that while these jackets excel in portability, they may lack insulation, making them less suitable for colder environments. The lightweight fabric can also affect durability, so businesses should evaluate their specific needs against the expected usage.

What Makes Anorak Style Rain Jackets a Good Choice for Casual Wear?

Anorak style rain jackets feature a half-zip design and hidden pockets, providing a casual yet functional option for team uniforms and casual wear. Their stylish appearance makes them appealing for a variety of settings, from outdoor activities to promotional events. However, B2B buyers should be aware of potential limitations in size options and consider whether the design aligns with their brand image. This style is versatile, but it may not fit all professional environments.

Why Choose Performance Layered Jackets for Extreme Conditions?

Performance layered jackets are constructed with multiple layers to enhance insulation and breathability, making them ideal for extreme weather conditions and outdoor adventures. Businesses in sectors like construction, outdoor recreation, or emergency services may find these jackets particularly beneficial. Although they provide excellent protection and durability, the higher cost and potential bulkiness may deter some buyers. Understanding the specific environmental challenges faced by employees can help in making informed purchasing decisions.

How Can Sublimated Warmup Jackets Enhance Team Representation?

Sublimated warmup jackets are designed with a soft interior and can be customized with team logos, making them perfect for sports teams and promotional events. Their relaxed fit ensures comfort, allowing athletes to move freely while representing their team. However, buyers should consider minimum order quantities, which can affect budget and inventory management. The stylish design not only boosts team morale but also serves as a valuable marketing tool when worn in public settings.

Key Industrial Applications of sublimated rain jacket

| Industry/Sector | Specific Application of Sublimated Rain Jacket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports & Recreation | Team uniforms for outdoor sports events | Enhances team branding and visibility during competitions | Minimum order quantities, customization options, and fabric durability |

| Corporate Branding | Promotional gifts for corporate events and outdoor activities | Strengthens brand identity and employee morale | Customization capabilities, fabric quality, and lead times |

| Outdoor Adventure Tourism | Uniforms for guides and staff in adventure tourism | Provides protection from weather while promoting the brand | Water resistance, breathability, and custom design options |

| Emergency Services | Rain gear for first responders in adverse weather conditions | Ensures safety and visibility during emergencies | Compliance with safety standards, reflective materials, and fit |

| Fashion & Retail | Custom apparel for fashion brands and retail stores | Unique designs that stand out in a competitive market | Trend awareness, fabric choice, and production timelines |

How Are Sublimated Rain Jackets Used in Sports & Recreation?

In the sports and recreation industry, sublimated rain jackets serve as essential team uniforms for outdoor events. They allow teams to showcase their branding prominently while providing protection against the elements. These jackets can be fully customized with team colors, logos, and designs, enhancing team identity and cohesion. For international buyers, considerations include the minimum order quantities and the durability of fabrics, particularly for regions with varying climates.

What Role Do Sublimated Rain Jackets Play in Corporate Branding?

Corporate branding often utilizes sublimated rain jackets as promotional gifts during events or outdoor activities. These jackets not only offer practical weather protection but also serve as a canvas for company logos and branding messages. This dual functionality strengthens brand identity and boosts employee morale. Buyers should evaluate customization options and fabric quality to ensure the jackets are suitable for long-term use, especially in diverse climates across Africa and South America.

How Are Sublimated Rain Jackets Beneficial in Outdoor Adventure Tourism?

In outdoor adventure tourism, sublimated rain jackets are crucial for staff and guides who face unpredictable weather conditions. These jackets are designed to be lightweight, water-resistant, and visually appealing, promoting the brand while ensuring the safety and comfort of employees. International buyers should focus on sourcing jackets that offer breathability and customization options to reflect their unique brand identity, which is vital in competitive tourist markets.

Why Are Sublimated Rain Jackets Important for Emergency Services?

Emergency services rely on sublimated rain jackets to provide first responders with essential weather protection during adverse conditions. These jackets often incorporate reflective materials for enhanced visibility, ensuring that personnel remain safe while performing their duties. Buyers in this sector must prioritize compliance with safety standards, fit, and durability, particularly in regions prone to severe weather, such as the Middle East and parts of Europe.

How Do Fashion Brands Utilize Sublimated Rain Jackets?

Fashion brands leverage sublimated rain jackets to create unique apparel that stands out in a crowded retail market. These jackets allow for vibrant designs and patterns, appealing to consumers looking for stylish yet functional outerwear. For B2B buyers in the fashion sector, it’s crucial to stay updated on current trends, choose high-quality fabrics, and understand production timelines to meet market demands effectively.

3 Common User Pain Points for ‘sublimated rain jacket’ & Their Solutions

Scenario 1: Customization Challenges in Order Fulfillment

The Problem: Many B2B buyers face significant challenges when it comes to customizing sublimated rain jackets for their brands. With a plethora of options available, from colors to designs, the task of selecting the right combination can be overwhelming. Furthermore, the risk of miscommunication regarding specifications can lead to delays in order fulfillment or receiving products that do not meet expectations. This is particularly concerning in regions where tight timelines are common, such as during the rainy season or for upcoming events.

The Solution: To mitigate these issues, it is crucial for buyers to establish clear communication channels with suppliers. Begin by creating a comprehensive design brief that outlines every detail, including color schemes, logos, and specific design elements. Utilize digital mockups or prototypes to visualize the final product before approval. Additionally, consider implementing a minimum order quantity (MOQ) strategy to ensure that your orders are economically viable while minimizing excess inventory. Suppliers who offer interactive design studios can also help streamline this process by allowing buyers to visualize their designs in real-time.

Scenario 2: Quality Assurance and Material Selection

The Problem: A common pain point for B2B buyers is ensuring that the materials used in sublimated rain jackets meet quality standards, especially in diverse climates such as those found in Africa and South America. Poor-quality fabrics can lead to issues such as inadequate water resistance, discomfort, and rapid wear and tear, resulting in dissatisfied customers and potential loss of business.

The Solution: To address quality concerns, buyers should prioritize suppliers who provide detailed specifications about fabric composition and performance characteristics. Request samples of the materials before placing a bulk order to evaluate their breathability, durability, and water resistance firsthand. In addition, engaging suppliers who are knowledgeable about regional weather conditions can provide insights into the most suitable materials. Look for certifications or third-party testing results that confirm the fabric’s performance, ensuring that your rain jackets will withstand the intended environmental conditions.

Scenario 3: Complications with Shipping and Logistics

The Problem: International shipping can often complicate the procurement process for sublimated rain jackets. Delays in shipping can disrupt supply chains, especially when orders are needed for specific events or promotional campaigns. Furthermore, navigating customs regulations and tariffs can add unexpected costs and challenges, particularly for businesses operating across multiple countries.

The Solution: To streamline logistics, establish a strong relationship with a supplier who has experience in international shipping. Inquire about their shipping practices and timelines to understand how they handle customs and tariffs. Consider utilizing a freight forwarder who specializes in B2B transactions to navigate potential pitfalls in the shipping process. Additionally, plan your orders well in advance, accounting for potential delays in production and shipping. Setting realistic lead times—ideally at least 30 days from order placement to delivery—will help ensure that your rain jackets arrive on time and in good condition, allowing you to meet your business needs effectively.

Strategic Material Selection Guide for sublimated rain jacket

What Are the Key Materials for Sublimated Rain Jackets?

When selecting materials for sublimated rain jackets, it is crucial to consider properties that enhance performance, durability, and suitability for various climates. Below, we analyze four common materials used in the production of sublimated rain jackets, focusing on their characteristics, advantages, disadvantages, and considerations for international B2B buyers.

How Does Polyester Perform in Sublimated Rain Jackets?

Key Properties: Polyester is a synthetic fabric known for its excellent moisture-wicking capabilities and resistance to shrinking and stretching. It maintains its shape well and is quick-drying, making it ideal for rain jackets.

Pros & Cons: The durability of polyester is a significant advantage, as it can withstand wear and tear over time. It is also relatively cost-effective, which appeals to manufacturers and buyers alike. However, polyester has a lower breathability compared to natural fibers, which may affect comfort in humid conditions.

Impact on Application: Polyester is compatible with sublimation printing, allowing for vibrant designs that are embedded into the fabric. This feature is essential for brands looking to create visually appealing products.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is vital. Buyers from regions like Europe may prefer eco-friendly polyester options, while those in warmer climates might prioritize breathability.

What Role Does Nylon Play in Sublimated Rain Jackets?

Key Properties: Nylon is another synthetic material known for its strength and elasticity. It is lightweight and has excellent abrasion resistance, making it suitable for outdoor wear.

Pros & Cons: The key advantage of nylon is its durability and resistance to water, which is essential for rain jackets. However, nylon can be more expensive than polyester, which may be a consideration for budget-conscious buyers. Additionally, it may not hold sublimated prints as well as polyester.

Impact on Application: Nylon’s water-resistant properties make it ideal for wet conditions, but its compatibility with sublimation printing can vary based on the specific blend used.

Considerations for International Buyers: Buyers from Africa and South America may prioritize cost-effectiveness and durability, while European buyers might focus on compliance with environmental regulations.

Why Is Ripstop Fabric Important for Rain Jackets?

Key Properties: Ripstop fabric, typically made from nylon or polyester, features a grid pattern that enhances its tear resistance. This makes it particularly useful in rugged environments.

Pros & Cons: The main advantage of ripstop fabric is its strength, which significantly reduces the likelihood of rips and tears. However, it can be more expensive to manufacture due to the specialized weaving process.

Impact on Application: Ripstop fabric is particularly suitable for outdoor activities and extreme weather conditions, providing additional safety for users.

Considerations for International Buyers: Buyers should consider the specific climate conditions of their regions. For example, buyers in the Middle East may require lightweight ripstop options for high temperatures.

How Does Waterproof Breathable Fabric Enhance Performance?

Key Properties: Waterproof breathable fabrics, often made from a combination of synthetic materials, are designed to keep water out while allowing moisture vapor to escape.

Pros & Cons: These fabrics provide excellent protection against the elements, making them ideal for rain jackets. However, they can be more complex to manufacture and may come at a higher cost.

Impact on Application: The combination of waterproofing and breathability is critical for active users who require comfort during physical activities in wet conditions.

Considerations for International Buyers: Compliance with international standards for waterproofing (such as JIS) is essential, especially for buyers in Europe, where performance testing is rigorous.

Summary Table of Material Selection for Sublimated Rain Jackets

| Material | Typical Use Case for sublimated rain jacket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | General outdoor wear | Excellent moisture-wicking and durability | Lower breathability | Medium |

| Nylon | Rugged outdoor activities | High strength and abrasion resistance | Higher cost compared to polyester | High |

| Ripstop Fabric | Extreme weather conditions | Tear-resistant and durable | More complex and expensive to manufacture | High |

| Waterproof Breathable Fabric | Active outdoor use in wet conditions | Superior protection and comfort | Higher manufacturing complexity and cost | High |

This strategic material selection guide provides B2B buyers with valuable insights into the various materials available for sublimated rain jackets, helping them make informed purchasing decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for sublimated rain jacket

What are the Key Stages in the Manufacturing Process of Sublimated Rain Jackets?

The manufacturing of sublimated rain jackets involves several critical stages that ensure both functionality and aesthetic appeal. Understanding these stages can help B2B buyers evaluate potential suppliers more effectively.

Material Preparation: What Materials Are Used?

The first step in the manufacturing process is the selection and preparation of materials. Commonly used fabrics for sublimated rain jackets include 100% polyester and polyester blends, known for their durability and moisture-wicking properties. The fabric undergoes a pre-treatment process to enhance its ability to absorb sublimation inks, ensuring vibrant and long-lasting prints. Buyers should ensure that suppliers source high-quality materials that meet international standards for wearability and environmental sustainability.

How Are Sublimated Rain Jackets Formed?

Once the materials are prepared, the next stage is forming the jacket. This involves cutting the fabric into specific patterns that correspond to the jacket design. Advanced cutting technologies, such as laser cutting, can be employed for precision and efficiency. This stage may also involve the sublimation process, where designs are printed onto transfer paper using sublimation inks. The paper is then placed on the fabric, and heat is applied, causing the ink to bond with the fabric fibers. This technique creates a seamless design that is resistant to fading, cracking, or peeling.

What Does the Assembly Process Entail?

After the fabric is cut and sublimated, the assembly stage begins. This includes stitching together various components such as sleeves, zippers, and linings. Many manufacturers use automated sewing machines for consistency and speed, but skilled labor is still crucial for detailing and quality control. During assembly, features like pockets, ventilation openings, and waterproof zippers are integrated to enhance functionality. Buyers should inquire about the assembly methods employed by suppliers to ensure they align with quality standards.

How is the Finishing Stage Conducted?

The final stage of manufacturing is finishing, where jackets are inspected for defects, cleaned, and prepared for packaging. This stage may also involve applying additional treatments, such as water repellents or anti-UV coatings, to enhance the jacket’s performance. Proper finishing ensures that the product not only looks appealing but also meets the functional expectations of end-users.

What Quality Assurance Measures Should B2B Buyers Expect?

Quality assurance (QA) is critical in ensuring that sublimated rain jackets meet international standards and customer expectations. Buyers should be aware of the QA measures that reputable suppliers implement.

Which International Standards Are Relevant for Quality Assurance?

Manufacturers of sublimated rain jackets often adhere to international quality standards such as ISO 9001, which sets criteria for a quality management system. Additionally, specific certifications like CE (Conformité Européenne) for products sold in Europe, or industry-specific standards such as API (American Petroleum Institute) for jackets used in certain industries, may also apply. Buyers should request documentation of these certifications to ensure compliance with relevant safety and quality guidelines.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral to the manufacturing process and typically include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials before production begins. Quality checks ensure that fabrics and components meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, random samples are taken to check for defects, stitching quality, and adherence to design specifications. This proactive approach helps catch issues early.

-

Final Quality Control (FQC): After assembly and finishing, each jacket undergoes a final inspection to ensure it meets quality standards. This includes checking for defects, verifying measurements, and ensuring that the sublimation prints are accurate and vibrant.

How Can B2B Buyers Verify Supplier Quality Control Processes?

To ensure that suppliers maintain high-quality standards, B2B buyers can take several steps:

What Are Effective Methods for Supplier Audits?

Conducting supplier audits is a key method for verifying quality control practices. Buyers can perform on-site audits or request third-party audits to assess the manufacturer’s facilities, processes, and compliance with international standards. This process provides insight into the operational practices and quality control measures employed by suppliers.

How Important Are Quality Reports and Testing Methods?

Requesting quality reports from suppliers is another effective way to verify their QC processes. These reports should detail the testing methods used, such as tensile strength tests, colorfastness tests, and waterproof testing, to ensure that the jackets meet specific performance criteria.

Why Should B2B Buyers Consider Third-Party Inspections?

Engaging third-party inspection services can offer an unbiased assessment of the product quality. These services can conduct inspections at various stages of production, providing comprehensive reports that highlight any issues or concerns. This additional layer of verification is particularly beneficial for international buyers from regions such as Africa, South America, the Middle East, and Europe, where communication barriers may exist.

What Nuances Should International Buyers Be Aware Of?

B2B buyers from different regions should be aware of specific nuances related to quality control. For instance, suppliers in Asia, such as Vietnam, may have different practices and standards compared to those in Europe, like Germany. Understanding these regional differences can help buyers make more informed decisions.

How Do Cultural and Regulatory Differences Affect Quality Assurance?

Cultural attitudes towards quality and regulatory requirements can vary significantly by region. Buyers should familiarize themselves with local regulations, consumer expectations, and industry standards to ensure that the products they source will meet their market’s needs. For example, European buyers may have stricter environmental regulations compared to those in South America.

Conclusion: Ensuring Quality in Sublimated Rain Jacket Manufacturing

In summary, understanding the manufacturing processes and quality assurance measures for sublimated rain jackets is crucial for B2B buyers. By focusing on key manufacturing stages, relevant quality standards, and verification methods, buyers can ensure they partner with reliable suppliers who deliver high-quality products that meet both functional and aesthetic requirements. This diligence not only enhances the buyer’s brand reputation but also contributes to customer satisfaction in a competitive marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sublimated rain jacket’

To successfully procure sublimated rain jackets, B2B buyers must navigate a series of critical steps to ensure quality, customization, and supplier reliability. This guide serves as a comprehensive checklist for sourcing sublimated rain jackets tailored to your business needs.

1. Define Your Technical Specifications

Establishing clear technical specifications is the first step in your sourcing journey. This includes deciding on materials, sizes, colors, and any additional features such as waterproofing or breathability. Clearly defined specifications help suppliers understand your exact needs and reduce the risk of miscommunication.

- Material Choice: Look for fabrics that offer durability and comfort, such as polyester blends.

- Customization Needs: Specify whether you need full sublimation or partial designs.

2. Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in sublimated rain jackets. Utilize online platforms, trade shows, and industry referrals to create a list of qualified candidates. A well-researched supplier base can significantly enhance your chances of finding the right partner.

- Supplier Reputation: Check for reviews and testimonials from other B2B buyers.

- Geographical Considerations: Focus on suppliers who understand your regional market dynamics, especially if sourcing from Africa, South America, the Middle East, or Europe.

3. Evaluate Supplier Capabilities

It’s essential to assess the capabilities of your shortlisted suppliers. This includes their production capacity, technology for sublimation, and customization options. A supplier’s ability to meet your requirements efficiently will impact your lead times and overall satisfaction.

- Production Capacity: Ask about minimum order quantities (MOQs) and turnaround times.

- Customization Technology: Verify if they use advanced techniques for sublimation printing that ensure high-quality designs.

4. Request Samples

Before finalizing any order, request samples of the sublimated rain jackets. This step allows you to evaluate the quality of materials, craftsmanship, and the accuracy of the sublimation process. Samples also provide an opportunity to assess fit and comfort.

- Quality Check: Inspect for color fidelity and fabric feel.

- Fit Testing: Ensure the samples align with your sizing specifications.

5. Discuss Pricing and Payment Terms

Engage in discussions about pricing structures and payment terms. Understanding the full cost of the jackets, including shipping and taxes, is crucial for budgeting. Ensure that the payment terms are favorable and align with your financial policies.

- Transparent Pricing: Request a detailed quote including all potential costs.

- Payment Flexibility: Discuss options such as deposits or payment upon delivery.

6. Verify Certifications and Compliance

Confirm that your chosen supplier complies with relevant certifications and quality standards. This is particularly important for international transactions where regulations may vary by region. Compliance ensures that the products meet safety and quality benchmarks.

- Certification Checks: Look for certifications related to quality management, such as ISO.

- Sustainability Practices: Inquire about eco-friendly practices, especially if your brand values sustainability.

7. Establish Communication Channels

Finally, set up clear communication channels with your supplier. Regular updates and open lines of communication can prevent misunderstandings and keep your project on track. Designate a point of contact on both sides for smoother interactions.

- Regular Updates: Schedule check-ins to monitor progress and address any issues.

- Crisis Management: Discuss how to handle potential delays or quality concerns proactively.

By following this step-by-step checklist, B2B buyers can effectively navigate the sourcing process for sublimated rain jackets, ensuring that they find a reliable supplier that meets their specific needs.

Comprehensive Cost and Pricing Analysis for sublimated rain jacket Sourcing

What Are the Key Cost Components in Sublimated Rain Jacket Production?

When sourcing sublimated rain jackets, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The fabric quality significantly impacts the price. Options like 100% nylon or polyester, known for their durability and water resistance, are common. Custom sublimation inks and coatings also add to material costs.

-

Labor: Labor costs vary by region and complexity of customization. Skilled workers are needed for intricate designs, which can increase labor expenses.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient production practices can help minimize overhead costs.

-

Tooling: Custom designs may require specialized tooling, which can be a one-time expense but must be considered for accurate pricing.

-

Quality Control (QC): Implementing stringent QC processes ensures product quality, which may incur additional costs but is essential for maintaining customer satisfaction.

-

Logistics: Shipping costs can vary based on location and order size. International shipping may involve tariffs and customs fees, adding to overall expenses.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding typical margins in your supplier’s market can aid in negotiation.

How Do Price Influencers Affect the Cost of Sublimated Rain Jackets?

Several factors influence the pricing of sublimated rain jackets:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often attract discounts. Suppliers may have different pricing tiers based on order size, making it beneficial to consolidate orders when possible.

-

Specifications and Customization: Custom designs, including unique patterns and logos, can significantly raise prices. Be clear about your requirements to obtain accurate quotes.

-

Materials: The choice of fabric and additional features (like waterproofing or breathability) can alter costs. Higher quality materials typically lead to higher prices but can enhance durability and performance.

-

Quality and Certifications: Jackets with specific certifications (e.g., eco-friendly materials) may command higher prices. Ensure that any certifications align with your brand’s values.

-

Supplier Factors: Supplier reputation, location, and production capacity can impact pricing. Established suppliers with a track record may charge a premium but often provide better quality assurance.

-

Incoterms: Understanding the terms of shipping can affect costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can shift responsibilities and costs between buyer and seller.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing Sublimated Rain Jackets?

To maximize value and minimize costs when sourcing sublimated rain jackets, consider the following tips:

-

Negotiate Prices: Always negotiate with suppliers. Be prepared to discuss your needs and how your order can benefit them, especially if you plan to place repeat orders.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial price. Consider long-term factors like durability, replacement rates, and shipping costs to assess the total cost over time.

-

Understand Pricing Nuances for International Markets: Familiarize yourself with import duties, local market conditions, and currency fluctuations, especially when sourcing from countries like Vietnam or Germany.

-

Leverage Relationships: Build strong relationships with suppliers. A good rapport can lead to better pricing, priority service, and advantageous payment terms.

-

Request Samples: Before placing large orders, request samples to evaluate quality and fit. This can prevent costly mistakes and ensure that the final product meets your expectations.

-

Stay Informed on Trends: Keep abreast of industry trends and innovations in fabrics and printing technologies. This knowledge can help you negotiate better and make informed decisions.

Disclaimer on Indicative Prices

Pricing for sublimated rain jackets can vary widely based on the factors outlined above. The information provided serves as a guideline; actual costs may differ based on specific supplier quotes and market conditions. Always conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing sublimated rain jacket With Other Solutions

When evaluating the best protective outerwear for various business needs, it’s essential to consider alternatives to sublimated rain jackets. These alternatives can offer different benefits and drawbacks, making them suitable for specific applications or preferences. Here, we compare sublimated rain jackets with two other popular options: traditional waterproof jackets and customizable windbreakers.

| Comparison Aspect | Sublimated Rain Jacket | Traditional Waterproof Jacket | Customizable Windbreaker |

|---|---|---|---|

| Performance | High breathability and moisture-wicking; vibrant designs | Excellent waterproofing; often heavier | Lightweight; good for mild rain and wind |

| Cost | Moderate to high (approx. $99+) | Varies widely ($50 to $150) | Generally lower ($30 to $70) |

| Ease of Implementation | Requires design proofs and longer lead times (30 days) | Readily available off-the-shelf | Easy to order with quick turnaround |

| Maintenance | Machine washable; retains colors well | Durable but may require special care | Easy to clean; less durable than jackets |

| Best Use Case | Branding events, team uniforms, sports | Outdoor activities, heavy rain | Casual wear, light outdoor use |

What Are the Key Advantages and Disadvantages of Traditional Waterproof Jackets?

Traditional waterproof jackets are designed to provide maximum protection against heavy rain and harsh weather conditions. They often feature advanced waterproofing technologies such as Gore-Tex or similar membranes, ensuring that the wearer stays dry. However, these jackets can be bulkier and less breathable compared to sublimated options, which may lead to discomfort during extended wear. Additionally, while the upfront cost can vary significantly, they generally have a longer lifespan due to their robust construction.

Why Consider Customizable Windbreakers as an Alternative?

Customizable windbreakers offer a lightweight solution suitable for mild weather conditions. They are often made from breathable materials, making them comfortable for active use. The cost-effectiveness of windbreakers is a significant advantage, especially for businesses looking to equip large teams without breaking the budget. However, windbreakers typically provide limited protection against heavy rain and may not meet the needs of users requiring more substantial weatherproofing.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right outerwear solution, B2B buyers must assess their specific requirements, including the environmental conditions and the intended use of the jackets. For branding opportunities and vibrant designs, sublimated rain jackets are ideal, particularly for teams and events. Conversely, businesses needing robust protection against extreme weather may opt for traditional waterproof jackets. If cost and quick availability are top priorities, customizable windbreakers can be a practical choice for everyday use. Ultimately, understanding these alternatives allows buyers to make informed decisions that align with their operational needs and branding strategies.

Essential Technical Properties and Trade Terminology for sublimated rain jacket

What Are the Key Technical Properties of a Sublimated Rain Jacket?

When sourcing sublimated rain jackets, understanding specific technical properties is crucial for ensuring product quality and meeting customer expectations. Here are some essential specifications to consider:

-

Material Composition

– Definition: The fabric used in sublimated rain jackets typically includes a blend of polyester and nylon. Polyester is favored for its durability and ability to hold vibrant colors, while nylon adds water resistance and breathability.

– B2B Importance: Choosing the right fabric composition affects the jacket’s performance in various weather conditions, influencing customer satisfaction and brand reputation. -

Water Resistance Rating

– Definition: Measured in millimeters, this rating indicates how much water pressure the fabric can withstand before leaking. A higher rating (e.g., 5000 mm) signifies better waterproofing.

– B2B Importance: For B2B buyers, understanding water resistance is critical, especially when catering to markets in regions with heavy rainfall. It ensures that the product meets the functional needs of end-users. -

Breathability

– Definition: This property measures the fabric’s ability to allow moisture vapor to escape while keeping water out. Breathable fabrics typically have a rating expressed in grams per square meter (g/m²).

– B2B Importance: A jacket that is breathable prevents overheating and discomfort during physical activities, making it more appealing to consumers who require performance wear. -

Fit and Sizing Tolerances

– Definition: This refers to the allowable variations in garment measurements to ensure proper fit. Tolerances are often specified in inches or centimeters.

– B2B Importance: Accurate sizing is essential for customer satisfaction and reducing return rates. B2B buyers must ensure that suppliers adhere to consistent sizing standards. -

Customization Options

– Definition: Customization can include color, design, and additional features such as pockets or zippers. The process often involves sublimation printing, where designs are embedded into the fabric.

– B2B Importance: Customization enhances brand visibility and allows companies to differentiate their products in competitive markets, making them more attractive to potential buyers.

What Are the Common Trade Terms Associated with Sublimated Rain Jackets?

Understanding industry terminology is vital for effective communication and negotiation in the B2B landscape. Here are some key terms that buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: B2B buyers often work with OEMs to create custom products, ensuring that specifications and quality standards are met. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their purchases and manage inventory effectively, particularly when dealing with custom sublimated products. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price quotes from suppliers for specific products or services.

– Importance: An RFQ allows buyers to compare costs and negotiate terms, ensuring they receive the best value for their investment. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of sellers and buyers for the delivery of goods.

– Importance: Understanding Incoterms is crucial for B2B transactions, as they outline shipping costs, risk management, and delivery responsibilities, impacting the overall transaction cost. -

Lead Time

– Definition: The time it takes from placing an order to the delivery of the product.

– Importance: Lead time affects inventory management and customer fulfillment. Buyers must communicate their requirements clearly to avoid delays in product availability.

By familiarizing themselves with these properties and terms, B2B buyers can make informed decisions when sourcing sublimated rain jackets, ensuring they meet market demands and customer expectations effectively.

Navigating Market Dynamics and Sourcing Trends in the sublimated rain jacket Sector

What Are the Key Trends Shaping the Global Sublimated Rain Jacket Market?

The sublimated rain jacket market is experiencing robust growth, driven by increasing demand for customizable apparel across various sectors such as sports, outdoor activities, and corporate branding. As consumers become more fashion-conscious, the need for unique and personalized designs has surged. This trend is particularly prevalent among B2B buyers in regions like Africa, South America, the Middle East, and Europe, where local brands are competing to establish a distinctive identity. Moreover, advancements in printing technology, particularly dye-sublimation, allow for high-quality, durable, and intricate designs that resonate with customers.

Emerging technologies such as 3D printing and digital fabric printing are also influencing sourcing strategies, enabling manufacturers to offer rapid prototyping and smaller production runs. This flexibility is appealing to international buyers who are looking to minimize inventory costs while still catering to the latest consumer trends. Additionally, the rise of e-commerce platforms is facilitating easier access to suppliers and manufacturers, creating a more competitive landscape for B2B buyers looking to source sublimated rain jackets.

How Important Is Sustainability and Ethical Sourcing in the Sublimated Rain Jacket Industry?

Sustainability is becoming a critical factor in the sourcing of sublimated rain jackets, as environmental consciousness grows among consumers and businesses alike. The production of synthetic fabrics used in rain jackets has a notable ecological impact, leading many companies to seek alternatives that are less harmful to the environment. Buyers are increasingly prioritizing suppliers that utilize recycled materials and sustainable production processes, recognizing that these practices can enhance brand reputation and customer loyalty.

Ethical sourcing is equally important, as B2B buyers are keen to ensure their supply chains are transparent and socially responsible. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® provide assurance that materials are sourced ethically and sustainably. By partnering with certified manufacturers, businesses can communicate their commitment to sustainability, which is increasingly influencing purchasing decisions across diverse markets.

What Is the Historical Evolution of Sublimated Rain Jackets in the B2B Landscape?

The evolution of sublimated rain jackets can be traced back to the development of dye-sublimation printing technology in the late 20th century. Initially used for promotional items and sportswear, the technique gained traction for its ability to produce vibrant, long-lasting prints. As outdoor activities gained popularity in the 2000s, so did the demand for functional yet stylish rain jackets.

Over the years, the sublimation process has become more sophisticated, allowing for intricate designs that cater to niche markets. This evolution has opened doors for customization in various sectors, including corporate branding and team sports, making sublimated rain jackets a staple in many B2B offerings. Today, the market is characterized by a blend of fashion, functionality, and sustainability, reflecting broader consumer trends and expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of sublimated rain jacket

-

How do I choose the right sublimated rain jacket supplier for my business?

Selecting the right supplier for sublimated rain jackets involves several key considerations. First, assess their experience in the industry, particularly with custom products. Look for reviews or testimonials from previous clients to gauge their reliability. It’s essential to request samples to evaluate the quality of materials and craftsmanship. Additionally, inquire about their production capacity, lead times, and customization options to ensure they can meet your business needs. Lastly, consider their communication style and responsiveness, as this can significantly impact your working relationship. -

What is the minimum order quantity (MOQ) for sublimated rain jackets?

The MOQ for sublimated rain jackets typically varies by supplier, but it often ranges from 6 to 50 pieces. Some manufacturers may have lower MOQs for reorders, while initial orders might require a higher quantity. When discussing MOQs, consider your budget and storage capabilities, as well as the potential for future orders. It’s advisable to negotiate with suppliers for favorable terms, especially if you plan to establish a long-term partnership or if you are ordering multiple styles or designs. -

What payment terms should I expect when sourcing sublimated rain jackets?

Payment terms can differ significantly among suppliers. Common practices include a deposit (usually 30-50%) upfront, with the balance due upon completion of production or before shipment. Some suppliers may offer net payment terms, allowing you to pay within a specified period after receiving the goods. It’s crucial to clarify payment methods accepted (e.g., wire transfer, credit card) and ensure that any terms are documented in the purchase agreement. Establishing trust through transparent payment terms can help foster a strong supplier relationship. -

How can I ensure quality assurance (QA) for my sublimated rain jackets?

To ensure quality assurance for your sublimated rain jackets, implement a multi-step QA process. Start by requesting detailed product specifications and conducting pre-production samples to assess material quality and printing accuracy. Arrange for inspections during production, either through third-party services or by visiting the facility if possible. After receiving the goods, conduct a thorough inspection to check for defects or discrepancies in design and functionality. Building a strong relationship with your supplier can also facilitate better quality control measures. -

What customization options are available for sublimated rain jackets?

Customization options for sublimated rain jackets are extensive and can include fabric choice, color schemes, and unique designs. Most suppliers offer a range of base styles and allow you to incorporate your branding elements, such as logos and graphics. Some manufacturers provide online design tools for easy customization, while others may offer design assistance. Additionally, you can specify features like pocket placement, zippers, and lining materials to tailor the jackets to your specific requirements, enhancing brand identity and functionality. -

What are the shipping options and costs associated with sublimated rain jackets?

Shipping options for sublimated rain jackets will depend on the supplier and your location. Most suppliers offer various carriers, including express and standard shipping, to accommodate different delivery timelines. Costs can vary based on order size, destination, and chosen shipping method. For larger orders, some suppliers may provide free shipping or discounts. It’s advisable to discuss shipping terms upfront, including tracking options and insurance for high-value shipments, to ensure a smooth delivery process. -

How do I handle international trade regulations when sourcing sublimated rain jackets?

When sourcing sublimated rain jackets internationally, it’s essential to understand and comply with trade regulations, tariffs, and import duties specific to your region. Research the regulations in your country and the country of origin to avoid unexpected costs. Ensure that your supplier provides the necessary documentation, such as certificates of origin and compliance with safety standards. Engaging a customs broker can also simplify the process, helping you navigate the complexities of international shipping and ensuring adherence to legal requirements. -

What should I consider regarding lead times for custom sublimated rain jackets?

Lead times for custom sublimated rain jackets generally range from 2 to 6 weeks, depending on the supplier’s capacity and the complexity of your order. Factors influencing lead time include design approval, production schedules, and shipping distances. To avoid delays, provide clear design specifications and approve samples promptly. It’s also wise to plan ahead for peak seasons, as demand can impact production timelines. Establishing a timeline with your supplier can help ensure that your order is fulfilled on schedule, aligning with your business needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Sublimated Rain Jacket Manufacturers & Suppliers List

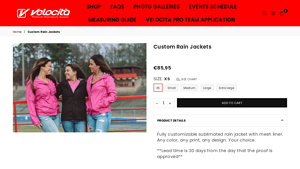

1. Velocita – Custom Rain Jackets

Domain: velocita-usa.com

Registered: 2009 (16 years)

Introduction: Custom Rain Jackets – Regular price $99.00. Fully customizable sublimated rain jacket with mesh liner. Available sizes: XS, Small, Medium, Large, Extra Large. Lead time is 30 days from the day that the proof is approved. Shipping: All orders processed within 3-4 business days after receiving paid order. Returns: No returns on custom products; contact for issues. Stock items can be returned within …

2. Moto Loko – Stealth Sublimated Rain Anorak

Domain: moto-loko.com

Registered: 2018 (7 years)

Introduction: Stealth Sublimated Customised Rain Anorak for Adults

3. Elevation Sports – Custom Waterproof Jackets

Domain: elevationsports.com

Registered: 2009 (16 years)

Introduction: Custom Waterproof Jackets from Elevation Sports keep you 100% dry in heavy rain. Features include custom embroidery for team logos and names. The jackets use special fabrics to ensure dryness, with high-end options featuring taped seams to prevent water penetration. Available brands include Nike, Under Armour, Marmot, and North Face, with various models like Torrent, Cloud Strike, and DryVent. Pro…

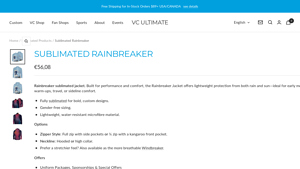

4. VC Ultimate – Sublimated Rainbreaker

Domain: vcultimate.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “Sublimated Rainbreaker”, “sale_price”: “$89.00”, “description”: “Rainbreaker sublimated jacket. Built for performance and comfort, the Rainbreaker Jacket offers lightweight protection from both rain and sun—ideal for early morning warm-ups, travel, or sideline comfort. Fully sublimated for bold, custom designs.”, “features”: {“gender_free_sizing”: true, “material”: “lightweight, …

5. Facebook – Rain Jacket

6. NTZ Sports – Custom Rain Jackets

Domain: ntzsportsonline.com

Registered: 2007 (18 years)

Introduction: Custom Rain Jackets Sublimated are meticulously crafted for optimal performance in rainy weather. They are designed to keep you 100% dry in severe rainstorms. Key features include:

– Fabrics: Taslan, Ripstop, Oxford Parachute, PVC Coated

– Features: Water-Repellent, Flexible, Lightweight

– Construction: Inside polyester mesh lining, hidden hood inside collar, overlapped full zip closure

– Sizes: A…

Strategic Sourcing Conclusion and Outlook for sublimated rain jacket

In the evolving landscape of custom apparel, particularly sublimated rain jackets, strategic sourcing plays a pivotal role in meeting the diverse needs of international markets. Buyers from regions such as Africa, South America, the Middle East, and Europe must focus on partnerships that emphasize customization, quality materials, and efficient lead times. The integration of sublimation technology not only enhances the aesthetic appeal of rain jackets but also ensures durability and comfort, providing a competitive edge in the marketplace.

Additionally, understanding the importance of minimum order quantities and shipping logistics can significantly impact sourcing decisions. By leveraging suppliers that offer flexible customization options and robust customer support, businesses can enhance their brand visibility while ensuring product quality.

Looking ahead, the demand for sublimated rain jackets is expected to grow, driven by consumer preferences for personalized and high-performance outerwear. International B2B buyers are encouraged to explore innovative sourcing strategies and establish strong collaborations with manufacturers. By doing so, they can position themselves to capitalize on emerging trends and drive sustainable growth in their respective markets. Now is the time to invest in quality and creativity—unlock the potential of sublimated rain jackets for your brand today.