Introduction: Navigating the Global Market for sublimated rain jacket

In an increasingly competitive global market, sourcing high-quality sublimated rain jackets can pose a significant challenge for B2B buyers, particularly those operating in diverse climates and regions such as Africa, South America, the Middle East, and Europe. These jackets not only serve as functional apparel but also as a canvas for branding and team identity, making it essential to find suppliers that offer customization options while maintaining durability and comfort. This guide aims to equip international buyers with the knowledge needed to navigate the complexities of the sublimated rain jacket market, covering key aspects such as types of jackets available, applications across various industries, effective supplier vetting processes, and cost considerations.

As you explore the comprehensive insights provided in this guide, you will gain a deeper understanding of the factors that influence purchasing decisions in different regions. From assessing material quality to evaluating lead times and shipping logistics, each section is designed to empower you to make informed choices that align with your business needs. By focusing on the specific requirements of markets like Brazil and Germany, this guide ensures that you can effectively address the unique demands of your target audience, enhancing your product offerings and competitive edge in the global apparel landscape. Whether you are a retailer, event organizer, or corporate buyer, mastering the art of sourcing sublimated rain jackets can significantly enhance your brand’s visibility and customer satisfaction.

Article Navigation

- Top 5 Sublimated Rain Jacket Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for sublimated rain jacket

- Understanding sublimated rain jacket Types and Variations

- Key Industrial Applications of sublimated rain jacket

- 3 Common User Pain Points for ‘sublimated rain jacket’ & Their Solutions

- Strategic Material Selection Guide for sublimated rain jacket

- In-depth Look: Manufacturing Processes and Quality Assurance for sublimated rain jacket

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘sublimated rain jacket’

- Comprehensive Cost and Pricing Analysis for sublimated rain jacket Sourcing

- Alternatives Analysis: Comparing sublimated rain jacket With Other Solutions

- Essential Technical Properties and Trade Terminology for sublimated rain jacket

- Navigating Market Dynamics and Sourcing Trends in the sublimated rain jacket Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of sublimated rain jacket

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for sublimated rain jacket

Understanding sublimated rain jacket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fully Sublimated Jacket | Custom designs, vibrant colors, and patterns | Sports teams, corporate events | Pros: High customization; Cons: Longer lead times |

| Lightweight Rainbreaker | Lightweight, breathable fabric with water resistance | Outdoor events, travel wear | Pros: Comfort; Cons: May lack full waterproofing |

| Insulated Rain Jacket | Added insulation for warmth in cold weather | Winter sports, outdoor workwear | Pros: Warmth; Cons: Heavier and bulkier |

| Packable Rain Jacket | Compact design that can be folded into a small pouch | Hiking, travel, emergency kits | Pros: Portability; Cons: Limited durability |

| Performance Windbreaker | Versatile for rain and wind, often with a sporty fit | Athletic teams, promotional giveaways | Pros: Multi-functional; Cons: Typically less formal |

What Are the Characteristics of Fully Sublimated Jackets?

Fully sublimated jackets are characterized by their ability to feature vivid, custom designs that are integrated into the fabric itself. This process allows for limitless color combinations and patterns, making them particularly popular among sports teams and corporate events seeking to enhance brand visibility. When purchasing, B2B buyers should consider the lead time for production, as these jackets often require a longer turnaround due to the customization process. Additionally, the ability to create unique designs can significantly enhance team spirit and brand identity.

How Do Lightweight Rainbreakers Differ in Use?

Lightweight rainbreakers are designed for comfort and breathability, making them ideal for outdoor events and travel. They offer water resistance without the bulk of traditional rain jackets, which appeals to buyers in sectors like tourism and outdoor recreation. When sourcing these jackets, B2B buyers should assess the fabric’s water resistance and breathability to ensure it meets the specific needs of their clientele. The trade-off for comfort is that these jackets may not provide full waterproof protection, which is an important consideration for heavy rain conditions.

Why Choose Insulated Rain Jackets for Cold Weather?

Insulated rain jackets combine waterproof materials with thermal insulation, making them suitable for winter sports and outdoor workwear. These jackets are essential for industries where employees are exposed to cold and wet conditions, such as construction or outdoor events in colder climates. Buyers should evaluate the insulation type and jacket weight to ensure warmth without compromising mobility. While they offer significant protection against cold weather, they can be bulkier and heavier, which may deter some users seeking lightweight options.

What Are the Benefits of Packable Rain Jackets?

Packable rain jackets are designed for convenience, folding into a compact size for easy transport. They are especially useful for hiking, travel, and emergency preparedness. B2B buyers should focus on the durability of the material and the jacket’s waterproof capabilities, as these factors will influence customer satisfaction. While these jackets excel in portability, their lightweight design may compromise long-term durability, making them less suitable for heavy-use scenarios.

How Do Performance Windbreakers Serve Different Needs?

Performance windbreakers are versatile garments that protect against both rain and wind, often featuring a sporty fit. They are popular among athletic teams and as promotional giveaways, appealing to buyers in the sports and fitness industries. When considering these jackets, B2B purchasers should assess the design features, such as pocket placement and ventilation, to ensure they meet the functional needs of the target audience. While they provide excellent multi-functionality, they may not be appropriate for more formal settings, which could limit their appeal in certain markets.

Key Industrial Applications of sublimated rain jacket

| Industry/Sector | Specific Application of Sublimated Rain Jacket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports and Recreation | Team uniforms for outdoor sports events | Enhances team visibility and brand identity, while providing weather protection | Customization options, bulk order discounts, lead time for production |

| Outdoor Tourism | Merchandise for adventure tours | Offers tourists a memorable keepsake while ensuring comfort and protection from the elements | Durability for diverse climates, lightweight materials, and design flexibility |

| Corporate Branding | Employee uniforms for outdoor events | Strengthens brand presence, promotes team spirit, and provides functional benefits | Quality of sublimation printing, fabric quality, and compliance with corporate branding guidelines |

| Education and Institutions | School uniforms for outdoor activities | Fosters school pride and identity, while providing weather protection for students | Size range availability, customization options for logos, and budget considerations |

| Event Management | Staff uniforms for festivals and outdoor events | Ensures staff are easily identifiable and comfortable, enhancing overall event experience | Quick turnaround times, minimum order quantities, and adaptability to various weather conditions |

How Are Sublimated Rain Jackets Used in Sports and Recreation?

In the sports industry, sublimated rain jackets are often utilized as team uniforms for outdoor events. These jackets not only provide essential weather protection but also enhance team visibility with vibrant, customized designs that display team logos and colors. For international buyers, particularly in regions with unpredictable weather, it’s crucial to source jackets that are lightweight, breathable, and durable to withstand various conditions. Buyers should consider customization options and bulk order discounts to maximize their investment.

What Role Do Sublimated Rain Jackets Play in Outdoor Tourism?

For outdoor tourism businesses, sublimated rain jackets serve as functional merchandise for adventure tours, offering tourists a practical keepsake that enhances their experience. These jackets protect against rain and wind while being stylish enough to encourage purchases. When sourcing, international buyers should focus on jackets that are made from durable, lightweight materials suitable for diverse climates, ensuring that they can withstand rigorous outdoor activities while remaining comfortable.

How Can Corporations Benefit from Sublimated Rain Jackets for Branding?

In the corporate sector, sublimated rain jackets are increasingly being used for employee uniforms at outdoor events. These jackets not only provide comfort and protection but also reinforce brand identity through customized designs. For B2B buyers, it is essential to consider the quality of the sublimation printing and fabric to ensure a professional appearance. Adhering to corporate branding guidelines while allowing for customization options can significantly enhance employee morale and brand visibility at events.

Why Are Sublimated Rain Jackets Important for Educational Institutions?

Educational institutions often use sublimated rain jackets as uniforms for outdoor activities, promoting school pride among students. These jackets protect students from inclement weather during events like field trips or outdoor sports. Buyers from schools and universities should prioritize options that offer a wide range of sizes and customization capabilities for school logos. Budget considerations are also vital, as institutions often seek cost-effective solutions without compromising on quality.

How Do Event Management Companies Utilize Sublimated Rain Jackets?

Event management companies frequently employ sublimated rain jackets as staff uniforms for festivals and outdoor events. These jackets ensure that staff members are easily identifiable, which enhances the overall experience for attendees. For international buyers in this sector, sourcing jackets with quick turnaround times and adaptability to various weather conditions is key. Additionally, understanding minimum order quantities and customization options can help streamline the procurement process, ensuring that staff are well-prepared for the event.

3 Common User Pain Points for ‘sublimated rain jacket’ & Their Solutions

Scenario 1: Delays in Custom Orders Affecting Timelines

The Problem: Many B2B buyers face the challenge of long lead times when ordering custom sublimated rain jackets. With typical production timelines stretching from three to five weeks, businesses that require these jackets for events, team uniforms, or promotional purposes often find themselves in a tight spot. This delay can impact marketing efforts, team cohesion, and overall brand representation, especially if the jackets are intended for a specific launch date or event.

The Solution: To mitigate delays, B2B buyers should prioritize suppliers that offer clear timelines and transparent communication throughout the ordering process. When sourcing sublimated rain jackets, it’s crucial to ask for a detailed production schedule upfront, including proof approval times and estimated shipping dates. Buyers can also consider placing orders well in advance, especially during peak seasons or before major events. Establishing a solid relationship with a reliable supplier can also lead to improved turnaround times and priority status for future orders. Additionally, opting for suppliers who provide pre-designed templates can speed up the approval process, as these designs often require less back-and-forth communication.

Scenario 2: Quality Assurance and Fabric Concerns

The Problem: Another prevalent issue faced by B2B buyers is the inconsistency in fabric quality and printing during the sublimation process. Buyers may receive jackets that do not match the agreed-upon specifications in terms of color vibrancy, fabric feel, or durability. This discrepancy can lead to dissatisfaction among teams or clients, resulting in potential financial losses and damage to the buyer’s reputation.

The Solution: To ensure high-quality sublimated rain jackets, buyers should conduct thorough research on potential suppliers, seeking those with established reputations for quality control. Requesting samples before placing bulk orders is essential, as this allows buyers to evaluate the fabric quality and printing accuracy firsthand. Additionally, it’s beneficial to inquire about the supplier’s production process and quality assurance protocols. Establishing clear specifications, including color codes and fabric types, in the order agreement can help hold suppliers accountable. Buyers should also consider reading reviews and case studies from other businesses to gauge the supplier’s reliability.

Scenario 3: Limited Customization Options

The Problem: B2B buyers often encounter limitations regarding customization options for sublimated rain jackets, which can be particularly frustrating when trying to match branding or design requirements. A lack of flexibility in color schemes, patterns, or sizes can hinder brand representation and make it difficult to cater to diverse team needs.

The Solution: To navigate this challenge, buyers should seek suppliers known for their extensive customization capabilities. Before committing to an order, buyers should engage in a discussion about available design options, including the ability to adjust colors, add logos, or create unique patterns. Utilizing online design tools provided by suppliers can streamline this process, allowing buyers to visualize their customizations before finalizing the order. Additionally, exploring suppliers that specialize in small batch orders can provide greater flexibility for unique or niche design requests. It’s also advisable to keep an open line of communication with the supplier during the design phase to ensure that all specifications are met and to discuss any potential limitations or creative solutions that may be available.

By proactively addressing these common pain points, B2B buyers can enhance their sourcing experience for sublimated rain jackets, ensuring timely delivery, quality assurance, and full customization that meets their business needs.

Strategic Material Selection Guide for sublimated rain jacket

When selecting materials for sublimated rain jackets, understanding the properties, advantages, and limitations of each material is crucial for B2B buyers. This guide analyzes four common materials used in sublimated rain jackets, focusing on their performance characteristics and implications for international markets, particularly in regions like Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Polyester for Sublimated Rain Jackets?

Polyester is one of the most commonly used materials for sublimated rain jackets due to its excellent moisture-wicking properties and resistance to shrinking and stretching. It can withstand a wide range of temperatures and is resistant to mildew and mold, making it suitable for humid climates. Polyester’s compatibility with sublimation printing allows for vibrant colors and intricate designs, enhancing the aesthetic appeal of the jackets.

Pros: Polyester is durable, lightweight, and cost-effective, making it an ideal choice for bulk orders. Its resistance to fading and easy care requirements add to its appeal for manufacturers and buyers alike.

Cons: While polyester is generally robust, it can be less breathable than other materials, which may affect comfort during extended wear. Additionally, lower-quality polyester can be prone to pilling.

Impact on Application: Polyester jackets are well-suited for promotional events, sports teams, and outdoor activities. They are compatible with sublimation printing, allowing for high-quality, full-color designs.

How Does Nylon Compare as a Material for Sublimated Rain Jackets?

Nylon is another popular choice for rain jackets, known for its exceptional strength and elasticity. It offers excellent resistance to abrasion and is lightweight, making it suitable for active use. Nylon also has a higher water resistance compared to polyester, which can be a key factor in rain-prone regions.

Pros: The durability and strength of nylon make it ideal for high-performance applications. Its lightweight nature enhances comfort, especially for sports and outdoor activities.

Cons: Nylon can be more expensive than polyester, which may deter some buyers, particularly in cost-sensitive markets. It also tends to absorb moisture, which can lead to longer drying times.

Impact on Application: Nylon jackets are ideal for outdoor sports teams and adventure gear, especially in regions with unpredictable weather patterns. They are compatible with sublimation printing, but care must be taken to ensure the printing process does not affect the material’s water resistance.

What Are the Advantages of Using Microfiber in Sublimated Rain Jackets?

Microfiber, a blend of polyester and polyamide, is increasingly popular for rain jackets due to its ultra-soft texture and lightweight properties. This material provides excellent water repellency and breathability, making it comfortable for wearers in various climates.

Pros: Microfiber’s softness enhances comfort, and its lightweight nature makes it easy to pack and carry. The material is highly effective in moisture management, keeping the wearer dry and comfortable.

Cons: While microfiber is durable, it may not be as robust as pure polyester or nylon, which could affect its lifespan in rugged conditions. Additionally, it can be more expensive due to its specialized manufacturing process.

Impact on Application: Microfiber jackets are suitable for casual wear and fashion-oriented applications, appealing to brands that prioritize comfort and style. They are also compatible with sublimation printing, allowing for vibrant designs.

What Should International Buyers Consider When Choosing Fabric for Sublimated Rain Jackets?

When selecting materials for sublimated rain jackets, international buyers must consider regional compliance and standards. For instance, European buyers may look for materials that meet DIN standards, while buyers in Brazil may prefer compliance with local regulations. Understanding the target market’s preferences for durability, comfort, and style is crucial, as is ensuring that the manufacturing processes align with sustainability practices, which are increasingly important in global markets.

Summary Table of Material Selection for Sublimated Rain Jackets

| Material | Typical Use Case for sublimated rain jacket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Sports teams, promotional events | Cost-effective and durable | Less breathable than other options | Medium |

| Nylon | High-performance outdoor gear | Strong and abrasion-resistant | Higher cost compared to polyester | High |

| Microfiber | Casual wear, fashion-oriented applications | Soft and lightweight | Less robust than nylon/polyester | Medium |

| Blended Fabrics | Versatile applications, fashion | Combines benefits of multiple materials | May vary in quality and performance | Medium |

This strategic material selection guide provides B2B buyers with actionable insights to make informed decisions when sourcing sublimated rain jackets, ensuring that they meet both performance and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for sublimated rain jacket

What are the Main Stages in the Manufacturing Process of Sublimated Rain Jackets?

The manufacturing process of sublimated rain jackets involves several critical stages, each designed to ensure the final product meets the highest quality standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step involves sourcing high-quality, lightweight, and water-resistant fabrics, commonly made from polyester or nylon. These materials are treated to enhance their water-repellent properties. Additionally, dyes and inks used in sublimation printing are selected for their vibrancy and adherence to fabric. This stage may also involve pre-washing fabrics to remove any impurities that could affect the dyeing process.

-

Forming: During this stage, the prepared fabrics are cut into specific patterns based on the design specifications. This cutting is often done using automated machines for precision. Some manufacturers employ laser cutting technology to ensure clean edges and reduce fabric waste. After cutting, the pieces are laid out for sublimation printing, where high-resolution designs are transferred onto the fabric using heat and pressure.

-

Assembly: Once printed, the fabric pieces are sewn together. This process requires skilled labor to ensure that seams are durable and aesthetically pleasing. Advanced sewing techniques, such as flat-lock stitching, are used to minimize bulk and enhance comfort. This stage may also include adding features like zippers, pockets, and adjustable hoods.

-

Finishing: The final stage involves quality checks and finishing touches. This includes ironing, trimming excess threads, and applying any final treatments, such as water repellents or UV coatings. The jackets are then folded, packed, and prepared for shipping.

What Quality Control Measures are Essential for Sublimated Rain Jackets?

Quality control (QC) is paramount in ensuring that sublimated rain jackets meet international standards and customer expectations. Effective QC measures encompass various checkpoints and testing methods throughout the manufacturing process.

-

International Standards Compliance: B2B buyers should be aware of relevant international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards indicates that the manufacturer has established processes to ensure quality and consistency. Additionally, industry-specific certifications like CE mark for safety or API standards for performance may apply, depending on the intended use of the jackets.

-

Quality Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. Fabrics and dyes are tested for quality, colorfastness, and any defects.

– In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are conducted to ensure that the assembly and sublimation processes are carried out correctly. This may include monitoring sewing techniques and printing accuracy.

– Final Quality Control (FQC): After assembly, finished products undergo thorough inspections. This includes checking for seam integrity, print quality, and overall aesthetics. Any defective items are either repaired or discarded. -

Common Testing Methods: Various tests are employed to ensure the jackets perform as expected. These include water resistance tests, colorfastness tests, and durability assessments. Some manufacturers may also conduct wear tests to evaluate comfort and functionality.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are actionable steps buyers can take:

-

Supplier Audits: Conducting audits of potential suppliers is an effective way to assess their manufacturing capabilities and quality control processes. This can be done in person or through third-party auditing firms that specialize in textile manufacturing.

-

Requesting Documentation: Buyers should request quality assurance documentation, including ISO certifications, QC reports, and testing results. This documentation provides insights into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can add an additional layer of assurance. These services conduct independent assessments at various stages of the manufacturing process, ensuring compliance with agreed-upon specifications.

-

Building Relationships with Local Agents: In regions such as Africa or South America, working with local agents familiar with the textile industry can facilitate better communication and understanding of supplier capabilities. They can provide valuable insights and help navigate potential cultural or logistical challenges.

What Are the QC and Certification Nuances for International B2B Buyers?

B2B buyers must navigate various nuances when it comes to quality control and certifications, especially when sourcing from international suppliers. Understanding these nuances can help mitigate risks and ensure product quality.

-

Regional Standards Variation: Different countries may have unique standards and regulations regarding textile manufacturing. For example, while European buyers may prioritize CE marking for safety, buyers from other regions may focus on different criteria. Understanding these variations can help buyers set appropriate expectations.

-

Cultural Considerations in Quality Perception: Cultural differences may influence perceptions of quality and acceptable standards. Buyers should be aware of these differences and communicate their quality requirements clearly to avoid misunderstandings.

-

Supply Chain Transparency: Ensuring transparency throughout the supply chain is essential for maintaining quality. Buyers should inquire about the sourcing of raw materials, production processes, and any subcontracting arrangements that may affect quality.

-

Sustainability and Ethical Practices: Increasingly, buyers are prioritizing suppliers that adhere to sustainable and ethical practices. Certifications related to environmental management (such as ISO 14001) or fair labor practices can enhance a supplier’s credibility.

By focusing on these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions, ensuring that the sublimated rain jackets they procure meet their specifications and uphold their brand standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sublimated rain jacket’

To assist B2B buyers in sourcing high-quality sublimated rain jackets, this guide provides a structured checklist. Each step is designed to ensure that your procurement process is efficient, cost-effective, and aligned with your business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to outline your specific requirements for sublimated rain jackets. This includes the desired materials, design specifications, sizes, and any unique features such as waterproofing or breathability.

– Consider the end-use: Are these jackets for outdoor sports, corporate events, or casual wear?

– Identify customization needs: Will you require branding options like logos or team colors?

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in sublimated rain jackets. Look for companies that have a strong reputation in the market and offer a range of customizable options.

– Check their portfolio: Review their previous work to assess quality and design capabilities.

– Examine customer reviews: Look for feedback on platforms like industry forums or social media to gauge customer satisfaction.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with industry standards. This is crucial for ensuring product quality and ethical manufacturing practices.

– Look for certifications: Such as ISO, which can indicate adherence to quality management principles.

– Assess sustainability practices: Ensure the supplier follows environmentally friendly practices, which can be a selling point for your customers.

Step 4: Request Samples

Once you have shortlisted potential suppliers, request samples of their sublimated rain jackets. This step is vital to assess the quality of materials, printing, and overall craftsmanship.

– Evaluate fit and comfort: Ensure the jackets meet your sizing requirements and are comfortable for the intended audience.

– Inspect print quality: Check the vibrancy and durability of the sublimated designs to ensure they align with your brand standards.

Step 5: Negotiate Pricing and Terms

Engage in discussions with your selected suppliers to negotiate pricing and terms. It’s important to understand the total cost of ownership, including shipping and customs if applicable.

– Inquire about bulk discounts: Many suppliers offer pricing benefits for larger orders.

– Clarify lead times: Ensure you understand the timeline for production and delivery, as this can impact your inventory planning.

Step 6: Review Shipping and Return Policies

Before finalizing your order, thoroughly review the supplier’s shipping and return policies. This can save you from unforeseen complications later on.

– Check shipping costs: Ensure you have a clear understanding of shipping fees and delivery timelines.

– Understand return policies: Inquire about the process for handling defective or unsatisfactory products, especially for custom orders.

Step 7: Place Your Order and Monitor Production

After completing the above steps, place your order and maintain communication with the supplier throughout the production process.

– Set up regular check-ins: This ensures you stay updated on the progress and can address any issues promptly.

– Establish quality checkpoints: If possible, arrange for inspections at various stages of production to ensure adherence to your specifications.

By following this comprehensive checklist, B2B buyers can streamline the sourcing process for sublimated rain jackets, ensuring they select the best supplier to meet their needs.

Comprehensive Cost and Pricing Analysis for sublimated rain jacket Sourcing

What Are the Key Cost Components for Sublimated Rain Jackets?

When sourcing sublimated rain jackets, understanding the cost structure is crucial for effective budget management and pricing negotiations. The primary cost components include:

-

Materials: The choice of fabric significantly impacts cost. High-quality, lightweight, water-resistant materials typically command higher prices but offer better durability and performance. Additionally, the availability of eco-friendly materials may influence sourcing decisions, especially in markets with growing sustainability concerns.

-

Labor: Labor costs vary widely depending on the manufacturing region. Countries with lower labor costs may provide initial savings, but this can be offset by potential quality control issues or longer lead times.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, equipment maintenance, and administrative expenses. In regions with high operational costs, such as Western Europe, these expenses can inflate the overall price of the jackets.

-

Tooling: Custom designs often require specialized tooling, which can add to upfront costs. It’s essential to consider these costs when evaluating suppliers, especially for custom orders that may require unique design setups.

-

Quality Control (QC): Implementing a robust QC process is vital to ensure that products meet the required specifications. However, this adds to the overall manufacturing cost. Buyers should verify the QC practices of potential suppliers to mitigate risks.

-

Logistics: Transportation costs can vary significantly based on distance, shipping method, and Incoterms. Import duties and tariffs, especially for international shipments, can further affect the total landed cost of the jackets.

-

Margin: Suppliers typically build in a profit margin that reflects their operational costs and market conditions. Understanding this margin can help buyers negotiate better pricing.

How Do Price Influencers Affect the Cost of Sublimated Rain Jackets?

Several factors can influence the pricing of sublimated rain jackets, particularly for B2B buyers:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQs) that can affect pricing. Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should assess their needs and consider consolidating orders to meet MOQs for better pricing.

-

Specifications and Customization: Highly customized jackets with unique designs or additional features (e.g., reflective materials, specialized pockets) generally incur higher costs. Buyers should clarify their specifications upfront to avoid unexpected expenses.

-

Materials and Quality Certifications: The use of high-quality materials and certifications (like ISO or OEKO-TEX) can elevate costs. However, these investments often yield long-term benefits in terms of product performance and customer satisfaction.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with proven track records may charge premium prices but often provide better quality assurance and service.

-

Incoterms: Understanding Incoterms is essential when negotiating prices. These terms define who is responsible for shipping, insurance, and tariffs, which can significantly impact the total cost.

What Are the Best Negotiation Tips for B2B Buyers?

To achieve cost-efficiency and ensure a favorable deal when sourcing sublimated rain jackets, consider the following tips:

-

Research Market Prices: Gather data on current market prices and trends to inform your negotiation strategy. This knowledge can provide leverage when discussing terms with suppliers.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider logistics, potential repair costs, and the longevity of the jackets to calculate the TCO, which can help justify a higher initial investment for better quality.

-

Communicate Clearly: Be explicit about your needs, including design preferences, delivery timelines, and quality expectations. Clear communication can prevent misunderstandings and foster a collaborative relationship with suppliers.

-

Request Samples: Before committing to a large order, request samples to assess quality. This can also help in negotiating better terms based on the product’s performance.

Conclusion

While sourcing sublimated rain jackets, understanding the cost structure and pricing influencers is essential for B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. By considering these factors and employing effective negotiation strategies, businesses can secure favorable pricing and ensure product quality that meets their needs. Always remember that the prices mentioned in this analysis are indicative and can vary based on specific circumstances and supplier agreements.

Alternatives Analysis: Comparing sublimated rain jacket With Other Solutions

When evaluating options for rain protection apparel, B2B buyers must consider various solutions that meet their specific needs. Sublimated rain jackets offer a unique blend of customization and performance; however, alternative products might also fulfill the requirements of different markets. This analysis compares sublimated rain jackets to two alternative solutions: standard waterproof jackets and windbreakers, providing insights into their respective strengths and weaknesses.

| Comparison Aspect | Sublimated Rain Jacket | Standard Waterproof Jacket | Windbreaker |

|---|---|---|---|

| Performance | High breathability and water resistance, customizable designs | Excellent water resistance, less breathability | Lightweight, offers limited water resistance |

| Cost | Moderate ($89 – $99) | Varies ($50 – $200) | Typically lower ($40 – $80) |

| Ease of Implementation | Requires design proof and longer lead times (30 days) | Quick production and availability | Readily available in stores |

| Maintenance | Easy care, but custom designs may fade | Durable, often machine washable | Easy care, may require special washing instructions |

| Best Use Case | Ideal for teams or brands needing custom designs | Suitable for outdoor activities or work uniforms | Great for casual wear or mild weather protection |

What are the Benefits and Drawbacks of Standard Waterproof Jackets?

Standard waterproof jackets are designed primarily for performance, often featuring advanced materials that provide excellent water resistance. These jackets are typically less customizable than sublimated options but are readily available and can cater to larger groups with uniform needs. The main drawback lies in their lack of breathability, which can lead to discomfort during intense physical activity. Additionally, while they may offer a lower initial cost, high-quality waterproof jackets can be expensive, especially when purchasing in bulk.

How Do Windbreakers Compare to Sublimated Rain Jackets?

Windbreakers serve as a lightweight alternative to rain jackets, providing some level of protection against wind and light rain. They are often more affordable and readily available, making them a popular choice for casual wear. However, their water resistance is limited compared to sublimated rain jackets, which may not be suitable for heavy rain conditions. Windbreakers excel in warm climates where breathability is key, but they lack the customization options that sublimated jackets provide, which can be a significant factor for brands looking to enhance visibility and identity.

Conclusion: How Should B2B Buyers Choose the Right Rain Jacket Solution?

Selecting the right rain jacket solution involves understanding specific needs and contexts. Buyers should consider the environment in which the jackets will be used, the importance of customization, and budget constraints. For teams or brands looking to make a statement with their apparel, sublimated rain jackets offer a compelling option. In contrast, if immediate availability and cost-effectiveness are paramount, standard waterproof jackets or windbreakers might be more suitable. Ultimately, the decision should align with the intended use and the branding strategy of the organization.

Essential Technical Properties and Trade Terminology for sublimated rain jacket

What Are the Key Technical Properties of a Sublimated Rain Jacket?

When sourcing sublimated rain jackets, understanding their technical specifications is crucial for ensuring product quality and meeting market demands. Here are some essential properties to consider:

-

Material Composition

Sublimated rain jackets are typically made from lightweight, water-resistant microfibers or polyester blends. These materials are designed to repel water while allowing breathability, making them suitable for various climates. For B2B buyers, choosing the right fabric ensures customer satisfaction and durability, which directly impacts brand reputation. -

Water Resistance Rating (WRR)

The water resistance rating indicates how effectively the jacket can withstand moisture. This is often measured in millimeters, with higher numbers indicating greater resistance. A WRR of 1,500 mm or more is generally suitable for moderate rain, while jackets rated above 5,000 mm are ideal for heavy downpours. This property is vital for businesses targeting outdoor enthusiasts or regions with frequent rainfall. -

Breathability (MVTR)

Moisture Vapor Transmission Rate (MVTR) measures how well the fabric allows perspiration to escape. High breathability ratings (measured in g/m²/24h) are essential for maintaining comfort during physical activities. For B2B buyers, selecting jackets with appropriate MVTR levels can enhance customer satisfaction and reduce returns due to discomfort. -

Sublimation Quality

The quality of sublimation printing affects color vibrancy and design longevity. High-quality sublimation ensures that the colors remain bright and do not fade with washing or exposure to sunlight. For businesses, investing in sublimation quality can differentiate their products in a competitive market, appealing to clients looking for custom designs that last. -

Size Tolerance

Size tolerance refers to the allowable deviation in garment dimensions during manufacturing. In sublimated jackets, this can be critical since sublimation often involves a hand-made process. A tolerance of ±1/2 inch is common. Understanding size tolerance helps B2B buyers manage customer expectations and minimize dissatisfaction related to fit. -

Lead Time

The lead time is the period required to produce and ship the jackets after an order is placed. Typically, this can range from 30 to 45 days, depending on customization levels. For B2B buyers, knowing lead times is essential for planning inventory and meeting customer demands, particularly in seasonal markets.

Which Trade Terms Are Commonly Used in the Sublimated Rain Jacket Industry?

Familiarity with industry terminology is crucial for effective communication and negotiation in B2B transactions. Here are some key terms to understand:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce products that are then branded and sold by another company. In the context of sublimated rain jackets, an OEM may manufacture the jackets based on a buyer’s specifications and branding requirements. Understanding OEM relationships can help buyers find reliable manufacturers for custom products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell in one order. This term is crucial for B2B buyers to understand as it affects inventory management and cash flow. Suppliers may set MOQs based on production costs and materials availability, impacting purchasing decisions. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. It typically includes detailed specifications, quantities, and delivery timelines. For B2B buyers, issuing RFQs is essential for comparing suppliers and securing the best pricing for sublimated rain jackets. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Understanding these terms helps B2B buyers manage logistics and costs effectively, ensuring smooth transactions when sourcing sublimated jackets from overseas manufacturers. -

Customs Duties

These are tariffs imposed by governments on imported goods. For B2B buyers, being aware of customs duties is vital for calculating total landed costs and ensuring compliance with international trade regulations when importing sublimated rain jackets. -

Lead Time

Beyond its product-specific meaning, lead time in trade refers to the duration from order placement to delivery. Understanding lead times is crucial for inventory planning and meeting customer demands, particularly in fast-moving markets.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing sublimated rain jackets, ensuring quality, compliance, and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the sublimated rain jacket Sector

What Are the Current Market Dynamics and Key Trends in the Sublimated Rain Jacket Sector?

The global market for sublimated rain jackets is witnessing significant growth driven by a combination of fashion trends, technological advancements, and changing consumer preferences. As outdoor activities become increasingly popular, especially in regions like Africa and South America where climate variability affects outdoor events, the demand for high-quality, stylish rainwear is on the rise. B2B buyers are particularly interested in customizable options that allow them to differentiate their offerings. The ability to fully personalize jackets with team logos and vibrant designs has become a key selling point, appealing to sports teams, outdoor retailers, and corporate clients.

Emerging technologies in fabric printing and sublimation are enhancing the quality and durability of these products. Innovations such as moisture-wicking fabrics and lightweight materials are increasingly preferred, especially in Europe and the Middle East, where consumers are looking for performance-oriented apparel. Additionally, the shift towards e-commerce platforms has made it easier for B2B buyers to source these products globally, facilitating faster lead times and improved inventory management.

How is Sustainability and Ethical Sourcing Impacting the Sublimated Rain Jacket Market?

Sustainability has become a crucial consideration for B2B buyers in the sublimated rain jacket sector. As environmental awareness grows, companies are increasingly held accountable for their sourcing practices. The demand for eco-friendly materials, such as recycled polyester and organic cotton, is on the rise, particularly among European buyers who prioritize sustainable fashion. This trend is further fueled by the growing regulatory frameworks in many regions, which encourage businesses to adopt sustainable practices.

Ethical supply chains are essential not only for compliance but also for brand reputation. Buyers are looking for manufacturers who can provide transparency in their sourcing processes, including fair labor practices and reduced environmental impact. Certifications such as Global Recycled Standard (GRS) and OEKO-TEX are becoming key indicators of a supplier’s commitment to sustainability. By prioritizing these factors, B2B buyers can not only meet consumer demands but also enhance their brand loyalty and market positioning.

How Has the Sublimated Rain Jacket Market Evolved Over Time?

The sublimated rain jacket market has evolved significantly over the past few decades. Initially, these jackets were primarily functional, designed to protect against the elements without much emphasis on style. However, as consumer preferences shifted towards fashion-forward activewear, manufacturers began to incorporate vibrant colors and customizable designs. This evolution has been particularly pronounced in regions with a strong sports culture, such as Brazil and Germany, where team spirit and branding play a significant role in consumer choices.

Moreover, advancements in sublimation technology have enabled more intricate designs and better fabric quality, allowing brands to offer products that are not only practical but also visually appealing. This shift has opened new avenues for B2B collaborations, as companies seek to align their offerings with the modern consumer’s desire for both functionality and aesthetics. The ongoing evolution of this market reflects broader trends in the apparel industry, emphasizing the importance of adaptability and innovation in meeting the diverse needs of international buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of sublimated rain jacket

1. How do I choose the right supplier for sublimated rain jackets?

Choosing the right supplier involves assessing their experience, product quality, and customization options. Look for suppliers with a solid reputation, positive customer reviews, and a portfolio showcasing their work. Verify their production capabilities, including lead times and minimum order quantities (MOQs). Additionally, consider their compliance with international trade regulations and their ability to handle logistics efficiently. Request samples to evaluate fabric quality and printing accuracy before making a commitment.

2. What customization options are available for sublimated rain jackets?

Most suppliers offer extensive customization options, including color, design, size, and material choices. You can typically select from a range of fabrics, add logos, and choose specific design elements to align with your brand identity. Some suppliers provide online design tools, making the process easier. Be sure to inquire about the artwork submission guidelines and any associated fees for custom designs, as these can vary by supplier.

3. What are the typical minimum order quantities (MOQs) for sublimated rain jackets?

MOQs for sublimated rain jackets can vary widely depending on the supplier and the complexity of the design. Generally, MOQs range from 10 to 50 pieces for custom orders. Some suppliers might impose higher MOQs for certain customization options. It’s essential to clarify these details upfront to ensure they align with your purchasing plans, especially if you are testing a new design or entering a new market.

4. How do I handle international shipping and logistics for bulk orders?

When sourcing sublimated rain jackets internationally, work closely with your supplier to understand their shipping options. Many suppliers have partnerships with logistics companies to facilitate smoother shipping processes. Be aware of potential customs duties, import taxes, and delivery timelines, which can vary by destination. Opt for a supplier that provides tracking information and can accommodate specific shipping requests, such as expedited shipping or preferred carriers.

5. What payment terms should I expect when ordering sublimated rain jackets?

Payment terms for bulk orders of sublimated rain jackets can vary by supplier. Common practices include upfront payment, partial deposits, or payment upon delivery. Ensure you discuss and agree upon payment terms before placing an order. It’s also advisable to confirm the accepted payment methods, which may include bank transfers, credit cards, or payment platforms like PayPal, especially for international transactions.

6. How can I ensure the quality of sublimated rain jackets?

To ensure quality, request samples from potential suppliers before placing a bulk order. Evaluate the fabric’s feel, durability, and print quality. Additionally, inquire about the supplier’s quality assurance processes, such as inspections during production and post-production checks. Look for certifications or adherence to industry standards that can provide further assurance of product quality.

7. What should I do if there is an issue with my order?

If you encounter issues with your sublimated rain jacket order, immediately contact your supplier’s customer service team. Be clear and concise about the problem, whether it’s related to quality, delivery, or incorrect items. Reputable suppliers will typically have a return or resolution policy in place. Ensure you document any discrepancies with photographs and communication for reference.

8. Are there any specific considerations for sourcing from regions like Africa, South America, or the Middle East?

When sourcing sublimated rain jackets from regions like Africa, South America, or the Middle East, consider local manufacturing capabilities and material availability. Cultural preferences may influence design choices, so research regional trends and styles. Additionally, be aware of trade agreements and tariffs that may affect pricing. Engaging with local suppliers can also streamline logistics and enhance communication, fostering better relationships and understanding of market needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Sublimated Rain Jacket Manufacturers & Suppliers List

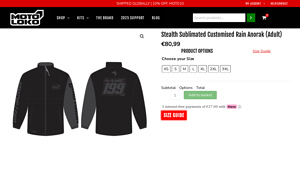

1. Moto Loko – Stealth Sublimated Rain Anorak

Domain: moto-loko.com

Introduction: Stealth Sublimated Customised Rain Anorak for Adults

2. Elevation Sports – Custom Waterproof Jackets

Domain: elevationsports.com

Introduction: Custom waterproof jackets designed to keep you 100% dry in heavy rain. Features include the ability to customize with team logos or names. Utilizes special fabrics to ensure dryness, with a focus on taped seams to prevent water penetration. Available brands include Nike, Under Armour, Marmot, and North Face, with options like Torrent Custom Waterproof Jackets and North Face DryVent Waterproof Jack…

3. USA TEAMWEAR – Custom Rain Jackets

Domain: usateamwear.com

Introduction: Rain Jackets | Custom Rain Jackets | USA TEAMWEAR

– Designed to keep you dry, warm, and protected in tough conditions.

– Suitable for training sessions, game days, or cooler weather.

– Combines water resistance with breathability and durability.

– Made from high-quality, lightweight materials for free movement.

– Price range: $18.00 – $70.00.

– Customization options available including team design…

4. Facebook – Rain Jacket

5. Pinterest – Fully Sublimated Rain Jackets

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Fully sublimated rain jackets in water-resistant fabric, very lightweight. Available for inquiries via DM or WhatsApp.

Strategic Sourcing Conclusion and Outlook for sublimated rain jacket

In the competitive landscape of sublimated rain jackets, strategic sourcing emerges as a critical factor for international B2B buyers. By partnering with reputable suppliers that offer customization options, quick turnaround times, and robust shipping policies, businesses can ensure they meet the diverse needs of their clientele across Africa, South America, the Middle East, and Europe. Key takeaways include the importance of understanding local market trends and preferences, as well as the value of bulk purchasing to secure better pricing and service terms.

Investing in high-quality, sublimated rain jackets not only enhances brand visibility but also fosters customer loyalty through unique and functional apparel. As demand for these products continues to grow, especially in regions experiencing fluctuating weather conditions, now is the time to evaluate your sourcing strategies.

Looking ahead, international buyers should seize the opportunity to leverage innovative design and manufacturing capabilities in sublimated rain jackets. By doing so, you can position your business to thrive in an evolving marketplace. Start exploring potential partnerships today to elevate your product offerings and meet the rising expectations of your customers.