Introduction: Navigating the Global Market for pvc trench coat

Navigating the global market for PVC trench coats presents a unique set of challenges for international B2B buyers, particularly when sourcing durable and stylish outerwear that meets diverse regional demands. As the fashion and safety industries increasingly converge, the need for high-quality PVC trench coats—offering both protection from the elements and contemporary aesthetics—has surged. This guide aims to provide a comprehensive overview of the various types of PVC trench coats available, their applications across different sectors, and essential considerations for supplier vetting.

By delving into the specifics of material quality, design features, and market trends, this resource equips buyers from Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Vietnam—with the insights needed to make informed purchasing decisions. We will explore factors such as cost analysis, warranty offerings, and compliance with regional safety standards, enabling businesses to align their purchases with both budgetary constraints and brand values.

In a marketplace where the demand for fashionable yet functional outerwear is growing, understanding these elements is crucial. This guide not only highlights the advantages of investing in PVC trench coats but also assists in establishing reliable supplier relationships that can enhance your product offerings and meet consumer expectations.

記事ナビゲーション

- Top 7 Pvc Trench Coat Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for pvc trench coat

- Understanding pvc trench coat Types and Variations

- Key Industrial Applications of pvc trench coat

- 3 Common User Pain Points for ‘pvc trench coat’ & Their Solutions

- Strategic Material Selection Guide for pvc trench coat

- In-depth Look: Manufacturing Processes and Quality Assurance for pvc trench coat

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘pvc trench coat’

- Comprehensive Cost and Pricing Analysis for pvc trench coat Sourcing

- Alternatives Analysis: Comparing pvc trench coat With Other Solutions

- Essential Technical Properties and Trade Terminology for pvc trench coat

- Navigating Market Dynamics and Sourcing Trends in the pvc trench coat Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of pvc trench coat

- 重要な免責事項および利用規約

- Strategic Sourcing Conclusion and Outlook for pvc trench coat

Understanding pvc trench coat Types and Variations

| タイプ名 | 主な特徴 | 主なB2Bアプリケーション | バイヤーのための簡単な長所と短所 |

|---|---|---|---|

| Heavyweight PVC Trench Coat | Durable 0.35mm PVC, detachable hood, storm front | Construction, outdoor work, safety | 長所だ: Highly durable, protective against elements. 短所だ: Bulkier, may limit mobility. |

| Lightweight PVC Raincoat | Thin PVC material, foldable, lightweight design | Hospitality, event management | 長所だ: Portable, easy to store. 短所だ: Less protective in extreme conditions. |

| Reflective PVC Trench Coat | Reflective strips for visibility, adjustable hood | Emergency services, outdoor events | 長所だ: Enhanced visibility, safety-focused. 短所だ: May be less stylish for casual wear. |

| Fashion PVC Trench Coat | Trendy designs, vibrant colors, high-fashion appeal | Retail, fashion industry | 長所だ: Attractive, brand differentiation. 短所だ: Higher price point, less functional. |

| Multi-Purpose PVC Trench Coat | Multiple pockets, adjustable features, versatile use | General outdoor, recreational activities | 長所だ: Functional, adaptable for various uses. 短所だ: May lack specialized features. |

What Are the Characteristics of Heavyweight PVC Trench Coats?

Heavyweight PVC trench coats are designed for rigorous use in demanding environments. Constructed with 0.35mm PVC and polyester backing, these coats offer superior durability and protection against harsh weather conditions. They often feature a storm front and a detachable hood, making them suitable for construction sites and outdoor work where safety and comfort are paramount. When considering a purchase, B2B buyers should evaluate the coat’s sizing options and warranty terms to ensure they meet workforce needs.

How Do Lightweight PVC Raincoats Differ from Other Types?

Lightweight PVC raincoats are crafted from thinner materials, making them easy to transport and store. They are ideal for industries such as hospitality and event management, where staff may need to quickly adapt to weather changes. While these coats provide basic protection against rain, their lightweight nature means they may not hold up in extreme conditions. B2B buyers should consider the trade-off between portability and durability when selecting these products for their teams.

What Are the Benefits of Reflective PVC Trench Coats?

Reflective PVC trench coats are specifically designed to enhance visibility in low-light conditions. Featuring reflective strips and adjustable hoods, these coats are essential for emergency services and outdoor events where safety is critical. The visibility they provide can prevent accidents and improve overall safety for workers. Buyers should assess the quality of the reflective material and the coat’s fit to ensure optimal performance in their intended applications.

Why Should Retailers Consider Fashion PVC Trench Coats?

Fashion PVC trench coats combine functionality with aesthetics, appealing to the retail and fashion industries. These coats often come in trendy designs and vibrant colors, allowing brands to differentiate themselves in a competitive market. However, their higher price point may limit accessibility for some buyers. Retailers should focus on aligning their product offerings with current fashion trends while ensuring that the quality meets customer expectations.

What Makes Multi-Purpose PVC Trench Coats Versatile?

Multi-purpose PVC trench coats are designed with versatility in mind, featuring multiple pockets and adjustable elements to cater to various activities. This adaptability makes them suitable for general outdoor use and recreational activities. Buyers should evaluate the specific features that align with their operational needs, as these coats can serve multiple roles, potentially reducing the need for specialized outerwear.

Key Industrial Applications of pvc trench coat

| 業界/セクター | Specific Application of PVC Trench Coat | ビジネスにとっての価値/利益 | このアプリケーションにおける主な調達先 |

|---|---|---|---|

| 農業 | Protective wear for agricultural workers during wet seasons | Enhances worker safety and productivity | Durability, resistance to chemicals, and size availability |

| 建設 | Rain protection for construction workers on-site | Minimizes downtime due to weather disruptions | Weight, breathability, and compliance with safety standards |

| Oil & Gas | Protective gear for workers in harsh weather conditions | Reduces risk of accidents and enhances visibility | Thickness, reflective features, and flame resistance |

| Food Processing | Hygiene protection for workers in wet environments | Ensures compliance with health regulations | Material safety, ease of cleaning, and waterproof features |

| 運輸・物流 | Rain protection for delivery personnel and drivers | Increases efficiency and reduces weather-related delays | Lightweight design, portability, and visibility features |

How is PVC Trench Coat Utilized in Agriculture?

In the agricultural sector, PVC trench coats are essential for protecting workers from rain and muddy conditions during planting and harvesting. These coats are designed to be durable and waterproof, ensuring that employees remain dry and comfortable while working in adverse weather. This protection not only enhances safety but also boosts productivity by minimizing disruptions caused by inclement weather. International buyers should consider sourcing trench coats that offer chemical resistance and are available in various sizes to fit over work clothing.

What Role Does PVC Trench Coat Play in Construction?

In construction, PVC trench coats serve as vital protective wear for workers exposed to rain and wet conditions on job sites. These coats help minimize downtime caused by weather, allowing projects to stay on schedule. The trench coats typically feature breathable materials and storm fronts to provide comfort while maintaining functionality. Buyers in this sector should prioritize sourcing options that comply with local safety regulations, offer a range of sizes, and include features like reinforced seams for added durability.

How is PVC Trench Coat Beneficial in Oil & Gas?

The oil and gas industry often requires workers to operate in harsh weather conditions, making PVC trench coats a critical part of their protective gear. These coats provide essential protection against rain and wind, while reflective strips enhance visibility in low-light conditions, reducing the risk of accidents. Businesses in this sector should focus on sourcing trench coats with flame-resistant properties and high durability to withstand the rigors of the job, especially in remote locations.

Why are PVC Trench Coats Important in Food Processing?

In food processing environments, PVC trench coats are used to maintain hygiene and protect workers from wet conditions. These coats prevent contamination and ensure compliance with health and safety regulations. Sourcing trench coats made from materials that are easy to clean and resistant to stains is crucial for businesses in this industry. Additionally, the waterproof feature helps maintain a dry working environment, which is vital for food safety standards.

How Can Transportation & Logistics Benefit from PVC Trench Coats?

In the transportation and logistics sector, PVC trench coats are used by delivery personnel and drivers to protect against rain and adverse weather while on the job. These coats enhance efficiency by allowing workers to remain dry and comfortable, reducing the likelihood of weather-related delays. When sourcing trench coats for this application, businesses should look for lightweight designs that are easy to store and transport, as well as features that improve visibility, such as reflective strips, to ensure safety on the road.

3 Common User Pain Points for ‘pvc trench coat’ & Their Solutions

Scenario 1: Sizing and Fit Challenges in PVC Trench Coats

問題だ: B2B buyers often face difficulties when it comes to sizing and fit for PVC trench coats, especially when catering to a diverse workforce. Different regions have varying body types and preferences, which complicates bulk purchasing decisions. A wrong size can lead to employee dissatisfaction and wasted resources, as returning items can be costly and time-consuming.

解決策 To effectively address sizing issues, B2B buyers should consider sourcing from manufacturers that provide detailed sizing charts and recommendations based on regional demographics. Prior to placing large orders, it’s advisable to request sample sizes for testing. This allows the workforce to try on the coats and provide feedback on fit and comfort. Additionally, suppliers that offer a range of sizes, including plus sizes and options for layering, can help ensure that the trench coats accommodate all employees. Establishing a clear communication channel with the supplier regarding sizing specifications will also help avoid future complications.

Scenario 2: Durability and Material Quality Concerns

問題だ: Buyers are often concerned about the durability and quality of PVC trench coats, particularly when used in harsh working environments. Many low-cost options may not withstand rigorous use, leading to premature wear and tear, which can affect employee safety and satisfaction.

解決策 To mitigate concerns over material quality, B2B buyers should prioritize sourcing trench coats made from heavyweight PVC with robust backing materials, as these are designed for durability. It’s essential to inquire about the specific thickness and types of materials used, as well as any certifications or standards the product meets for industrial use. Requesting product samples for testing in real-world conditions can also provide insights into longevity and performance. Moreover, establishing a relationship with reputable suppliers who provide warranties can offer additional peace of mind regarding product quality.

Scenario 3: Limited Customization Options for Branding

問題だ: B2B buyers often find that many PVC trench coats lack customization options, which are essential for branding and team identity. This can be especially problematic for companies looking to maintain a professional appearance while ensuring their staff is protected from the elements.

解決策 To overcome the limitation of customization, buyers should seek suppliers that offer a variety of branding options such as screen printing, embroidery, or even reflective strips for visibility. When negotiating with manufacturers, inquire about their capacity to produce customized trench coats in bulk, including color choices and logo placements. It’s also beneficial to collaborate with a supplier that has experience in producing branded workwear, as they can offer insights into the best practices for maintaining the integrity of the coat’s material while applying designs. Establishing a partnership with a vendor that values customization can enhance the professional image of the workforce while providing necessary protection against weather conditions.

By addressing these common pain points with actionable solutions, B2B buyers can make informed decisions that enhance employee satisfaction and operational efficiency.

Strategic Material Selection Guide for pvc trench coat

When selecting materials for PVC trench coats, B2B buyers must consider various factors that influence performance, durability, and compliance with international standards. Below, we analyze four common materials used in the production of PVC trench coats, focusing on their properties, advantages, disadvantages, and specific considerations for international markets.

What are the Key Properties of PVC in Trench Coats?

PVC (Polyvinyl Chloride) is a widely used synthetic plastic polymer known for its versatility and durability. It typically exhibits excellent resistance to water, chemicals, and UV light, making it suitable for outdoor wear. PVC trench coats often feature a thickness ranging from 0.25mm to 0.35mm, which balances flexibility and protection. The material is also relatively lightweight, which enhances wearer comfort during prolonged use.

What are the Advantages and Disadvantages of Using Heavyweight PVC?

Heavyweight PVC, often used in trench coats, provides superior protection against harsh weather conditions. Its thickness contributes to enhanced durability and resistance to tears and abrasions. However, the increased weight can lead to reduced comfort during extended wear, especially in warmer climates. Additionally, heavyweight PVC may have a higher manufacturing complexity due to the need for specialized equipment to handle thicker materials.

How Does Polyester Backing Enhance PVC Trench Coats?

Polyester backing is commonly used with PVC to improve comfort and breathability. This combination allows for moisture-wicking properties, reducing the discomfort associated with sweating. While polyester backing enhances the overall feel of the trench coat, it may increase production costs and complicate the manufacturing process. Moreover, the durability of the polyester can vary, impacting the overall longevity of the trench coat.

What are the Compliance and Standard Considerations for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must consider compliance with various safety and quality standards, such as ASTM (American Society for Testing and Materials) and DIN (Deutsches Institut für Normung). In markets like Saudi Arabia and Vietnam, understanding local regulations regarding chemical safety and environmental impact is crucial. Buyers should also be aware of the potential for warnings related to materials, such as those associated with PVC, which may contain phthalates that require disclosure.

Summary Table of Material Selection for PVC Trench Coats

| 素材 | Typical Use Case for PVC Trench Coat | 主な利点 | 主な欠点/制限 | 相対コスト(低/中/高) |

|---|---|---|---|---|

| Heavyweight PVC | Industrial and outdoor wear | Excellent durability and weather resistance | Heavier weight may reduce comfort | ミディアム |

| Polyester Backing | Enhanced comfort and breathability | Moisture-wicking and soft feel | Increased manufacturing complexity | ミディアム |

| Lightweight PVC | Casual and fashion-oriented trench coats | Flexibility and lightweight | Less durable than heavyweight options | 低い |

| Eco-friendly PVC | Sustainable fashion lines | Reduced environmental impact | 生産コストの上昇 | 高い |

This strategic material selection guide provides essential insights for B2B buyers in the PVC trench coat market. By understanding the properties, advantages, and limitations of each material, businesses can make informed decisions that align with their operational needs and compliance requirements across different international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for pvc trench coat

What are the Key Stages in the Manufacturing Process of PVC Trench Coats?

The manufacturing process of PVC trench coats is multifaceted, comprising several critical stages that ensure the final product meets quality standards and functional requirements.

-

材料の準備: The first step involves sourcing high-quality PVC material, often with a polyester backing for added durability and comfort. Suppliers must ensure that the PVC used complies with international regulations, such as REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) in the EU, which governs the safe use of chemicals.

-

成形: The prepared PVC is then cut into patterns based on the trench coat design. Advanced techniques such as ultrasonic welding or high-frequency welding are employed to bond PVC pieces together without the need for stitching, which can compromise waterproofing. This forming process also includes the creation of features like pockets, hoods, and ventilation openings.

-

組立: During assembly, the various components of the trench coat are joined. This stage may involve attaching zippers, buttons, and other accessories. Quality control measures, such as visual inspections, are crucial at this point to ensure that all parts align correctly and function as intended.

-

仕上げ: The final stage includes applying any necessary treatments, such as water repellents or coatings that enhance durability. The trench coats are also subjected to quality checks to ensure they are free from defects. Any excess material is trimmed, and the products are prepared for packaging.

How is Quality Assurance Implemented in PVC Trench Coat Production?

Quality assurance (QA) is vital in the production of PVC trench coats, ensuring that the end products meet both customer expectations and industry standards.

-

International Standards: Adhering to international quality standards such as ISO 9001 is essential. This standard outlines the requirements for a quality management system (QMS), ensuring that manufacturers consistently produce quality products. Additional certifications like CE marking may be required for products sold in the European market, indicating compliance with health, safety, and environmental protection standards.

-

品質管理のチェックポイント: Effective QA processes incorporate several checkpoints:

– 受入品質管理(IQC): This involves inspecting raw materials upon arrival to ensure they meet specified criteria before production begins.

– インプロセス品質管理(IPQC): During manufacturing, random samples are taken to assess adherence to specifications. This may include checking weld integrity or verifying that features like zippers function correctly.

– 最終品質管理(FQC): Once production is complete, finished trench coats undergo thorough inspections to ensure they are free of defects and meet all design specifications. -

Testing Methods: Common testing methods for PVC trench coats include:

– 防水試験: Assessing the coat’s ability to repel water under various conditions.

– 耐久性試験: Evaluating how the material withstands wear and tear over time.

– Chemical Resistance Testing: Ensuring that the PVC can resist degradation when exposed to various substances.

B2Bバイヤーはサプライヤーの品質管理をどのように検証できるか?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to mitigate risks.

-

サプライヤー監査: Conducting audits of potential suppliers can provide invaluable insights into their manufacturing processes and quality control measures. These audits should assess adherence to international standards and the effectiveness of their QMS.

-

Requesting Quality Reports: Buyers should request detailed quality assurance reports, including results from IQC, IPQC, and FQC inspections. These documents should outline any issues found during testing and the corrective actions taken.

-

第三者検査: Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and the quality of the final product. This is particularly important for buyers who are unable to visit manufacturing sites due to geographical constraints.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

When sourcing PVC trench coats internationally, buyers must navigate several nuances related to quality control:

-

Cultural Differences in Quality Standards: Different regions may have varying interpretations of quality standards. Buyers should ensure that they clearly communicate their expectations and understand the standards that suppliers adhere to.

-

Logistical Challenges: Buyers should be aware of potential logistical issues that may arise during shipping, such as damage or delays. Incorporating quality checks at multiple points in the supply chain can help mitigate these risks.

-

規制遵守: International regulations can vary significantly. Buyers need to ensure that the products they import comply with local regulations in their target markets, which may require additional certifications or labeling.

-

Long-term Relationships: Building strong relationships with suppliers can facilitate better communication regarding quality expectations and improvements. Engaging in ongoing dialogue about quality control can lead to enhanced product development and customer satisfaction.

By understanding these manufacturing processes and quality assurance protocols, B2B buyers can make informed decisions when sourcing PVC trench coats, ensuring they receive products that meet their operational needs and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pvc trench coat’

はじめに

This sourcing guide is designed to help international B2B buyers effectively procure PVC trench coats. As demand for protective and stylish outerwear rises across various industries, understanding the key steps in sourcing these garments can significantly impact your purchasing decisions. This checklist outlines essential actions to ensure you select the right suppliers and products for your needs.

1. 技術仕様の定義

Establishing clear technical specifications is the first step in sourcing PVC trench coats. This includes determining the material thickness, waterproofing capabilities, and additional features such as hoods or reflective strips. By defining these criteria upfront, you can streamline your search for suppliers who meet your exact requirements.

- Consider usage: Will these trench coats be used in industrial settings, or are they for fashion purposes?

- Look for certifications: Ensure that the materials meet safety and environmental standards relevant to your market.

2. Research Potential Suppliers

Conduct thorough research to identify potential suppliers capable of delivering high-quality PVC trench coats. Focus on manufacturers with experience in producing similar products and positive reviews from other B2B buyers.

- Check online directories: Utilize platforms like Alibaba, Global Sources, or industry-specific trade shows to find reputable suppliers.

- Evaluate their product range: A diverse product lineup can indicate a supplier’s capability and flexibility in meeting your needs.

3. Verify Supplier Certifications

Before proceeding with any supplier, it’s critical to verify their certifications. Look for compliance with international standards such as ISO, as well as any specific certifications for PVC materials.

- Request documentation: Suppliers should provide certificates that demonstrate their adherence to quality and safety regulations.

- Understand local regulations: Different regions may have unique standards; ensure your suppliers comply with regulations applicable to your target market.

4. サンプル請求

Requesting samples is a vital step to assess the quality of the trench coats. This allows you to evaluate the material, craftsmanship, and overall design before making a bulk order.

- Assess durability: Examine the stitching, weight of the PVC, and functionality of features like zippers and hoods.

- Test functionality: If possible, conduct wear tests to ensure the coat performs well under expected conditions.

5. 価格と条件の交渉

Once you have identified a suitable supplier and evaluated samples, the next step is to negotiate pricing and terms. This includes discussing bulk discounts, payment terms, and delivery timelines.

- Consider total cost of ownership: Look beyond the initial price; factor in shipping, duties, and potential tariffs.

- Discuss warranty and return policies: Ensure that you understand the supplier’s warranty coverage and return process in case of defects or dissatisfaction.

6. Establish a Communication Plan

Effective communication is crucial for a successful sourcing relationship. Establish a clear plan for regular updates and feedback throughout the production and delivery process.

- Set expectations: Determine how often you will communicate and through which channels (email, phone, etc.).

- Document agreements: Keep records of all agreements and discussions to prevent misunderstandings later.

7. Plan for Logistics and Distribution

Finally, consider how you will handle logistics and distribution of the trench coats once they arrive. This includes storage, inventory management, and distribution channels.

- Evaluate local partnerships: Collaborate with local logistics providers to streamline the import process.

- Plan for demand fluctuations: Assess your inventory needs based on seasonal trends or market demands to ensure you have enough stock without overcommitting.

By following this checklist, B2B buyers can navigate the sourcing process for PVC trench coats more effectively, ensuring they select high-quality products that meet their business needs.

Comprehensive Cost and Pricing Analysis for pvc trench coat Sourcing

What Are the Key Cost Components in PVC Trench Coat Production?

When sourcing PVC trench coats, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

材料: The most significant cost driver is the quality of PVC and any additional materials such as polyester backing, zippers, and hoods. Higher quality materials will increase the base cost but can lead to better durability and customer satisfaction.

-

労働: Labor costs can vary significantly based on the region where the coats are manufactured. For instance, labor costs in Southeast Asia may be lower compared to Europe or North America, impacting the overall pricing.

-

製造間接費: This includes costs related to utilities, factory rent, and equipment maintenance. Efficient manufacturing processes can help lower these overheads, which can be passed on as savings to buyers.

-

工具: Investment in tooling for production molds or specialized equipment can be substantial. However, if the production volume is high, these costs can be amortized over a larger number of units, reducing the per-unit cost.

-

品質管理(QC): Implementing robust QC measures ensures product consistency and compliance with safety standards. While this may add to initial costs, it can prevent costly recalls and enhance brand reputation.

-

物流: Shipping costs depend on the distance from the manufacturing site to the buyer’s location, as well as the chosen shipping method. Understanding Incoterms is essential for determining who bears these costs.

-

マージン: Suppliers typically apply a markup to cover their costs and generate profit. This margin can vary based on market demand, competition, and the supplier’s positioning.

How Do Price Influencers Affect the Cost of PVC Trench Coats?

Several factors can influence the final pricing of PVC trench coats:

-

数量/MOQ: Minimum Order Quantities (MOQ) often dictate pricing. Larger orders can lead to discounts, while smaller orders may incur higher per-unit costs.

-

仕様とカスタマイズ: Unique design features or customizations can lead to higher costs. Buyers should weigh the benefits of customization against potential price increases.

-

材料の品質と認証: Coats made from certified materials (like eco-friendly PVC) may carry a premium price but can enhance brand value and appeal, particularly in markets with stringent regulations.

-

サプライヤー要因: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to perceived reliability and quality assurance.

-

インコタームズ: Different Incoterms can significantly affect total costs. For example, CIF (Cost, Insurance, and Freight) means the supplier covers transport, while EXW (Ex Works) requires the buyer to handle all shipping costs, which can lead to significant differences in pricing.

What Are the Best Negotiation Tips for B2B Buyers of PVC Trench Coats?

To achieve cost-efficient procurement, B2B buyers should consider the following strategies:

-

Research and Compare: Gather quotes from multiple suppliers to understand market rates. This will empower you during negotiations.

-

Negotiate Based on Total Cost of Ownership (TCO): Instead of focusing solely on the initial purchase price, consider factors such as durability, maintenance costs, and potential returns. A higher upfront cost may be justified by lower long-term costs.

-

ボリューム・ディスカウントの活用: If your business can commit to larger orders, use this as leverage to negotiate better pricing or terms.

-

地元のサプライヤーを探す: For buyers in regions like Africa or South America, sourcing from local manufacturers can reduce shipping costs and lead times, which may offset higher production costs.

-

価格設定のニュアンスを理解する: Be aware of seasonal pricing fluctuations and market trends that could impact costs. For instance, prices may rise during peak seasons or due to raw material shortages.

Conclusion: Navigating the Complexities of PVC Trench Coat Sourcing

While the pricing landscape for PVC trench coats can be complex, understanding the underlying cost components and price influencers can help B2B buyers make informed decisions. Engaging in strategic negotiations and focusing on the total cost of ownership can yield significant savings and long-term value. It’s crucial to remain adaptable and informed about market conditions, especially in diverse regions such as Africa, South America, the Middle East, and Europe.

Disclaimer: The prices mentioned in the reference materials are indicative and may vary based on market conditions, supplier capabilities, and buyer negotiations. Always verify current pricing and terms directly with suppliers before making procurement decisions.

Alternatives Analysis: Comparing pvc trench coat With Other Solutions

Understanding Alternatives to PVC Trench Coats in B2B Markets

In the competitive landscape of protective outerwear, particularly for international B2B buyers, evaluating alternatives to PVC trench coats is essential. While PVC trench coats offer robust protection against rain and harsh weather conditions, there are other solutions that may better suit specific needs, preferences, or budgets. This analysis will compare PVC trench coats with two viable alternatives: waterproof nylon trench coats and heavy-duty rain suits.

比較表

| 比較の側面 | PVC Trench Coat | Waterproof Nylon Trench Coat | Heavy-Duty Rain Suit |

|---|---|---|---|

| パフォーマンス | Excellent waterproofing; durable | Good waterproofing; lightweight | Superior waterproofing; heavy-duty |

| コスト | Moderate ($22.34 – $3,250) | Lower ($30 – $150) | Moderate ($25 – $75) |

| 実施しやすさ | Easy to wear; available in multiple sizes | Easy to wear; often comes in standard sizes | Requires layering; may need size adjustments |

| メンテナンス | Low maintenance; wipe clean | Moderate; machine washable | Low maintenance; wipe clean |

| ベスト・ユースケース | Industrial applications; fashion-forward | Casual wear; light outdoor activities | Heavy-duty outdoor work; extreme weather |

代替案の詳細な内訳

Waterproof Nylon Trench Coat

Waterproof nylon trench coats are a lightweight alternative that offers decent protection against moisture while being more breathable than PVC. They are typically less expensive, making them an appealing option for budget-conscious buyers. However, their performance may not match that of PVC in extreme conditions. Ideal for casual wear and light outdoor activities, these coats are easy to clean and maintain. The downside is that they may not provide the same level of durability or protection as PVC trench coats, especially in industrial settings.

Heavy-Duty Rain Suit

Heavy-duty rain suits provide superior waterproofing and are designed for extreme weather conditions, making them suitable for industries such as construction and agriculture. These suits often come in two-piece designs, allowing for flexibility and ease of movement. While they can be bulkier than PVC trench coats, their robust construction can withstand harsh environments, making them a reliable choice for outdoor workers. However, they may require more effort to put on and take off, and their thickness can limit breathability. The cost is generally moderate, but it can vary based on the quality of the materials used.

結論ニーズに合ったソリューションの選択

When selecting the right outerwear solution, B2B buyers must consider their specific requirements, including the nature of their work environment, budget constraints, and desired level of protection. PVC trench coats stand out for their durability and fashion appeal, particularly in industrial settings and creative industries. Conversely, waterproof nylon trench coats may suit those seeking lightweight options for less demanding conditions, while heavy-duty rain suits are ideal for extreme weather and high-intensity work. By carefully evaluating these alternatives, businesses can make informed decisions that align with their operational needs and budgetary considerations.

Essential Technical Properties and Trade Terminology for pvc trench coat

When sourcing PVC trench coats for B2B purposes, understanding the essential technical properties and relevant trade terminology is crucial for making informed purchasing decisions. Below, we delve into the key specifications and industry jargon that will aid international buyers in evaluating their options effectively.

What are the Key Technical Properties of PVC Trench Coats?

1. Material Grade

PVC trench coats are typically constructed from different grades of Polyvinyl Chloride (PVC). The material’s thickness is often specified in millimeters (mm), with common weights ranging from 0.25mm to 0.5mm. Heavier grades, like 0.35mm, offer enhanced durability and resistance to wear, making them suitable for harsher environments. Understanding the material grade helps buyers assess the coat’s longevity and suitability for specific applications.

2. Waterproof Rating

A critical property for trench coats is their waterproof rating, often measured in millimeters of water resistance. A higher rating (e.g., 5000mm) indicates better protection against heavy rain and wet conditions. This specification is vital for industries such as agriculture and construction, where workers are frequently exposed to rain and need reliable protection.

3. Breathability

Breathability refers to the coat’s ability to allow moisture vapor to escape while preventing water from entering. Features like mesh vents can enhance breathability. For B2B buyers, selecting breathable materials is important to ensure comfort for wearers engaged in high-activity tasks, reducing sweat accumulation and maintaining productivity.

4. Size and Fit

PVC trench coats are available in various sizes, often ranging from Medium (M) to 4X Large (4XL). A full-cut design allows for layering over other clothing, which is critical for colder climates. Understanding sizing specifications ensures that companies can provide adequate options for all employees, promoting safety and comfort on the job.

5. Closure Type

The closure mechanism, such as snap or zip, plays a significant role in the coat’s functionality. Snap closures may provide easier access and adjustment, while zippers can offer a more secure fit against wind and rain. Buyers should consider the closure type based on the operational environment and user preferences.

Which Trade Terminology Should B2B Buyers Be Familiar With?

1.OEM(相手先ブランド製造)

This term refers to companies that manufacture products that may be branded and sold by another company. Understanding OEM relationships can help buyers find reliable suppliers that can meet specific design and quality standards.

2.MOQ(最小注文数量)

MOQ indicates the smallest number of units that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, especially for businesses looking to minimize upfront costs while ensuring a steady supply.

3.RFQ (見積依頼書)

An RFQ is a document that a buyer sends to suppliers requesting pricing and terms for specific products. This process is crucial for comparing offers and negotiating better deals, allowing buyers to make cost-effective decisions.

4.インコタームズ(国際商業条件)

These terms define the responsibilities of buyers and sellers in international shipping. Understanding Incoterms helps businesses clarify shipping costs, risks, and responsibilities, which is particularly important for international transactions involving PVC trench coats.

5.リードタイム

Lead time refers to the time taken from placing an order to delivery. Knowing the lead time helps businesses plan inventory and avoid stockouts, ensuring they can meet customer demand without delays.

By grasping these technical properties and trade terms, B2B buyers can navigate the procurement of PVC trench coats more effectively, ensuring they select products that meet their operational needs while also optimizing costs and logistics.

Navigating Market Dynamics and Sourcing Trends in the pvc trench coat Sector

What Are the Key Trends Influencing the PVC Trench Coat Market?

The global PVC trench coat market is witnessing a resurgence fueled by several key trends and market dynamics. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly drawn to the versatility and functionality of PVC trench coats. Factors such as changing weather patterns and heightened awareness of personal safety during inclement weather have spurred demand. Additionally, the rise of e-commerce platforms has simplified sourcing processes, allowing buyers to access diverse suppliers and products from across the globe.

Emerging technologies are playing a pivotal role in transforming sourcing strategies. Innovations in manufacturing, such as digital printing and automated production lines, are enhancing product customization and reducing lead times. Furthermore, the integration of AI and data analytics in inventory management and supply chain logistics is empowering businesses to optimize their operations and minimize costs. B2B buyers should consider these advancements to stay competitive in an evolving marketplace.

How Is Sustainability Shaping the PVC Trench Coat Industry?

Sustainability is becoming a critical factor in the PVC trench coat sector, prompting B2B buyers to prioritize ethical sourcing and environmentally friendly materials. The environmental impact of PVC production has raised concerns, particularly regarding its lifecycle and the potential for pollution. Therefore, brands are increasingly exploring alternative materials and eco-friendly practices, such as using recycled PVC or biodegradable options, to meet consumer expectations and regulatory demands.

Ethical supply chains are essential for building brand trust and ensuring compliance with international standards. Buyers are encouraged to seek suppliers that have established sustainability certifications, such as Global Recycled Standard (GRS) or OEKO-TEX, which indicate responsible sourcing practices. Furthermore, transparency in the supply chain not only enhances brand reputation but also aligns with the growing consumer demand for environmentally conscious products. As B2B buyers navigate this landscape, investing in sustainable partnerships will be crucial for long-term success.

What Is the Historical Context of PVC Trench Coats in the Market?

The PVC trench coat has evolved significantly since its inception, originally designed for functionality and protection against the elements. Initially popularized during the mid-20th century, these coats served primarily as practical outerwear for workers in various industries. Over the decades, they have transitioned from utilitarian garments to fashion statements, influenced by cultural shifts and celebrity endorsements.

In recent years, the PVC trench coat has re-emerged as a trendy item, particularly in fashion-forward markets. High-profile designers have incorporated PVC into their collections, showcasing the material’s versatility and appeal. This evolution highlights the importance of understanding market trends for B2B buyers, as the PVC trench coat now represents a blend of practicality and style that caters to diverse consumer needs. By recognizing the historical context, buyers can better anticipate future trends and adapt their sourcing strategies accordingly.

Frequently Asked Questions (FAQs) for B2B Buyers of pvc trench coat

-

How do I ensure the quality of PVC trench coats from suppliers?

To ensure quality, start by requesting samples from potential suppliers to evaluate the material, stitching, and overall construction. Look for certifications that indicate compliance with international safety standards, such as ISO or CE markings. It’s also beneficial to read reviews or testimonials from other B2B buyers. Conducting a factory audit can provide insights into the manufacturing processes and quality control measures in place. Establish clear quality assurance criteria in your purchase agreements to minimize risks. -

What features should I consider when sourcing PVC trench coats?

When sourcing PVC trench coats, consider features such as waterproofing, durability, and breathability. Look for coats made from heavyweight PVC with reinforced seams and storm flaps for added protection. Additional features like detachable hoods, adjustable cuffs, and reflective strips for visibility can enhance functionality. Also, assess the sizing options available to accommodate different body types, which is particularly important for international markets with diverse demographics. -

What is the typical minimum order quantity (MOQ) for PVC trench coats?

The MOQ for PVC trench coats varies by supplier, but it typically ranges from 100 to 1,000 units. Factors influencing MOQ include the supplier’s production capacity, customization options, and material availability. For B2B buyers, negotiating the MOQ can be possible, especially if you are willing to pay a premium for smaller batches. Always clarify the MOQ during initial discussions to ensure it aligns with your inventory needs and budget. -

How can I customize PVC trench coats for my brand?

Customizing PVC trench coats typically involves selecting fabric colors, adding logos, or modifying design elements like length and pockets. Most manufacturers offer customization options, but it’s crucial to discuss this early in the negotiation process. Be clear about your design specifications and ask for prototypes to evaluate before mass production. Keep in mind that custom orders may have higher MOQs and longer lead times, so plan accordingly. -

What are the payment terms commonly used in international transactions for PVC trench coats?

Payment terms for international transactions can vary widely, but common practices include letters of credit, wire transfers, and payment upon delivery. Many suppliers may require a deposit (typically 30-50%) upfront, with the balance due before shipment. It’s essential to agree on clear payment terms in the contract to avoid misunderstandings. Additionally, consider currency fluctuations and transaction fees, which can affect overall costs. -

How do I handle shipping logistics for PVC trench coats?

Shipping logistics for PVC trench coats involve selecting the right shipping method, such as air freight for speed or sea freight for cost-effectiveness. Work with freight forwarders who understand international trade regulations and customs clearance procedures. Ensure that your supplier provides the necessary documentation, such as commercial invoices and packing lists. Plan for potential delays, especially during peak seasons, and factor shipping times into your inventory management strategy. -

What quality assurance processes should I implement when purchasing PVC trench coats?

Implementing quality assurance processes involves setting clear specifications for the trench coats and conducting inspections at various production stages. Consider hiring third-party inspection services to verify that products meet your standards before shipment. Establish a returns policy for defective items and communicate this with your suppliers. Regularly reviewing supplier performance can help maintain quality and foster long-term partnerships. -

How do I vet suppliers of PVC trench coats effectively?

To effectively vet suppliers, start by researching their reputation within the industry. Look for certifications, years in business, and customer reviews. Request references from other B2B clients to gauge their experiences. Conduct factory visits or virtual tours to assess production capabilities and working conditions. It’s also wise to check for compliance with local and international regulations, especially concerning labor practices and environmental standards.

重要な免責事項および利用規約

⚠️ 重要な免責事項

メーカー、技術仕様、市場分析に関する内容を含め、本ガイドラインで提供される情報は、情報提供と教育目的のみのものです。専門的な調達アドバイス、財務アドバイス、または法的アドバイスを提供するものではありません。

情報の正確性、最新性には万全を期していますが、誤謬、脱漏、古い情報については責任を負いかねます。市場の状況、企業の詳細、技術水準は変更される場合があります。

B2Bバイヤーは、独自の徹底的なデューデリジェンスを実施しなければならない。 購入を決定する前に。これには、サプライヤーに直接問い合わせること、認定を確認すること、サンプルを請求すること、専門家に相談することなどが含まれる。本ガイドブックに記載された情報を信頼するリスクは、読者が負うものとします。

Top 7 Pvc Trench Coat Manufacturers & Suppliers List

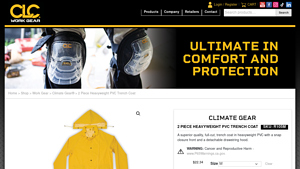

1. Goclc – 2 Piece Heavyweight PVC Trench Coat

ドメイン goclc.com

Registered: 2007 (18 years)

はじめに {“name”: “2 Piece Heavyweight PVC Trench Coat”, “sku”: “R105”, “price”: “$22.34”, “sizes”: [“M”, “L”, “XL”, “2XL”, “3XL”, “4XL”], “material”: “heavyweight (0.35mm) PVC with polyester backing”, “features”: [“full-cut design”, “snap closure front”, “detachable drawstring hood”, “storm front coat with double fly snap”, “rear mesh vents for breathability”, “full-cut sizes to fit over clothing”], “warr…

2. Etsy – PVC Trench Coats

ドメイン etsy.com

Registered: 2004 (21 years)

はじめに This company, Etsy – PVC Trench Coats, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

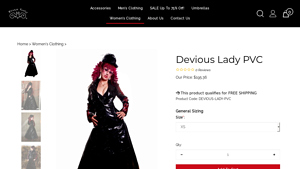

3. Hilary’s Vanity – Devious Lady PVC Trench Coat

ドメイン hilarysvanity.com

Registered: 2008 (17 years)

はじめに {“product_name”: “Devious Lady PVC”, “product_type”: “Full-Length PVC Trench Coat”, “material”: “Heavy PVC”, “features”: [“Back-Cinch Corset”, “Button Down Front”, “Arcane Red Detail Embroidery”], “lining”: “100% Polyester”, “price”: “$195.36”, “product_code”: “DEVIOUS-LADY-PVC”, “available_sizes”: [“XS”, “S”, “M”, “1X”, “2X”, “3X”, “4X”]}

4. Pinterest – PVC Rainwear

ドメイン ピンタレスト・ドット・コム

登録:2009年(16年)

はじめに PVC raincoat, Women’s fashion, Rain wear, Pvc Puffer Jacket, Pvc Trench Coat, Transparent Vinyl Raincoat, Mantel Cape, Black Latex Trench Coat, Plastic Raincoat, Transparent Pvc Hose Raincoat

5. Reddit – PVC Trench Coat

6. RK Safety – Men’s Waterproof Long Raincoat

ドメイン rksafety.com

登録:2014年(11年)

はじめに Men’s Waterproof Long Raincoat PVC Trench Coat – Orange

– Color: Neon Orange

– Sizes Available: Small, Medium, Large, Extra Large, 2XL, 3XL, 4XL

– Price: $39.04 (Regular Price: $50.93)

– Material: 100% Polyester

– Features: 1-Inch Reflective Strip for visibility, Hooded with adjustable string pull, Comes with storage bag, Machine washable.

7. Karen Millen – 18.01 PVC Trench Coat

ドメイン karenmillen.com

登録:1997年(28年)

はじめに Product Name: 18.01 PVC Trench Coat

Product Code: BKK05874

Price: $89.00 (originally $299.00, -70% off)

Collaboration: Karen Millen x 18.01LONDON

Style: Double-breasted trench coat with a longline silhouette

Material: Main: 100% Polyurethane

Features: Lustrous sheen, gold tone accents on buttons, belt, and epaulettes, buckle belt, front pockets, shoulder epaulettes

Model Information: Wears UK size…

Strategic Sourcing Conclusion and Outlook for pvc trench coat

In today’s competitive marketplace, strategic sourcing of PVC trench coats presents a valuable opportunity for international B2B buyers. By focusing on high-quality materials, such as heavyweight PVC with polyester backing, businesses can ensure their products meet diverse climatic demands while offering durability and functionality. The versatility of trench coats, designed for both protective and aesthetic purposes, allows companies to cater to various industries, from fashion to industrial applications.

Furthermore, establishing strong relationships with suppliers can lead to better pricing, enhanced product quality, and improved supply chain efficiency. With the growing demand for weather-resistant apparel in regions like Africa, South America, the Middle East, and Europe, understanding market-specific needs is crucial. Buyers should prioritize suppliers who offer customization options and reliable warranties, ensuring that their investments are safeguarded against defects.

Looking ahead, the PVC trench coat market is poised for growth, driven by advancements in material technology and evolving consumer preferences. B2B buyers are encouraged to explore innovative designs and sustainable sourcing practices that align with global trends. By embracing these strategies, businesses can position themselves as leaders in their respective markets, ready to capitalize on the rising demand for high-quality PVC trench coats.