Introduction: Navigating the Global Market for raincoat shoe cover

In today’s unpredictable weather patterns, sourcing reliable raincoat shoe covers has become a vital concern for businesses operating in sectors such as construction, food service, and outdoor recreation. As companies aim to protect their employees and maintain operational efficiency during inclement weather, the demand for high-quality, waterproof shoe covers is surging. This comprehensive guide serves as a resource for international B2B buyers navigating the complex global market for raincoat shoe covers, especially those from regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Vietnam.

Throughout this guide, we will explore the diverse types of raincoat shoe covers available, their specific applications across various industries, and critical factors for supplier vetting. Buyers will gain insights into pricing structures, material quality, and the importance of compliance with international safety standards. By addressing common challenges and providing actionable solutions, this guide empowers decision-makers to make informed purchasing choices that align with their business needs. Whether you are looking for durable, reusable options or cost-effective disposable alternatives, understanding the nuances of the market will enable you to enhance your procurement strategy and ensure that your workforce remains protected and productive, regardless of the weather conditions.

Article Navigation

- Top 3 Raincoat Shoe Cover Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for raincoat shoe cover

- Understanding raincoat shoe cover Types and Variations

- Key Industrial Applications of raincoat shoe cover

- 3 Common User Pain Points for ‘raincoat shoe cover’ & Their Solutions

- Strategic Material Selection Guide for raincoat shoe cover

- In-depth Look: Manufacturing Processes and Quality Assurance for raincoat shoe cover

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘raincoat shoe cover’

- Comprehensive Cost and Pricing Analysis for raincoat shoe cover Sourcing

- Alternatives Analysis: Comparing raincoat shoe cover With Other Solutions

- Essential Technical Properties and Trade Terminology for raincoat shoe cover

- Navigating Market Dynamics and Sourcing Trends in the raincoat shoe cover Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of raincoat shoe cover

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for raincoat shoe cover

Understanding raincoat shoe cover Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Waterproof Shoe Covers | Made from durable, waterproof materials; often reusable | Construction, cleaning, food service | Pros: Cost-effective, protect footwear. Cons: May not fit all shoe sizes. |

| Disposable Shoe Covers | Single-use, lightweight, and easy to wear | Medical, food processing, event management | Pros: Hygienic, convenient. Cons: Less durable, higher long-term costs. |

| Heavy-Duty Boot Covers | Reinforced materials for extreme conditions; often insulated | Outdoor work, heavy machinery, agriculture | Pros: Excellent protection, durable. Cons: Bulkier, may be more expensive. |

| High-Traction Shoe Covers | Specialized grip for wet or slippery surfaces | Hospitality, outdoor events, logistics | Pros: Enhanced safety, prevents slips. Cons: May wear out faster on rough surfaces. |

| Custom-Fit Shoe Covers | Tailored to specific shoe models; various colors available | Retail, promotional events, brand marketing | Pros: Professional appearance, brand visibility. Cons: Higher upfront costs, longer lead times. |

What Are the Key Characteristics of Waterproof Shoe Covers?

Waterproof shoe covers are designed to protect footwear from moisture and dirt, making them ideal for industries like construction and food service. They are typically made from durable materials like polyethylene or rubber, ensuring longevity and protection. When purchasing, businesses should consider the fit and ease of use, as some models may not accommodate all shoe sizes effectively.

How Do Disposable Shoe Covers Benefit Various Industries?

Disposable shoe covers are lightweight and designed for single use, making them a popular choice in medical and food processing environments. Their hygienic nature ensures that contaminants are not tracked into sensitive areas. While they offer convenience and ease of disposal, businesses should weigh the higher long-term costs against the benefits of cleanliness and safety.

What Makes Heavy-Duty Boot Covers Suitable for Extreme Conditions?

Heavy-duty boot covers are crafted from reinforced materials that provide superior protection in harsh environments, such as agriculture or heavy machinery operations. They often feature insulation for added comfort. Buyers should consider the bulkiness and potential higher costs but can benefit from the long-lasting durability these covers offer, which can ultimately save money over time.

Why Are High-Traction Shoe Covers Essential in Certain Work Environments?

High-traction shoe covers are designed with specialized grip features to prevent slips on wet or slippery surfaces, making them essential in hospitality and logistics sectors. Their safety benefits can reduce workplace accidents, but businesses should be aware that these covers may wear out more quickly on rough surfaces.

How Do Custom-Fit Shoe Covers Enhance Brand Visibility?

Custom-fit shoe covers are tailored to specific shoe models, often featuring branding opportunities through various colors and designs. This type of cover is particularly useful for retail and promotional events where a professional appearance is crucial. While they may incur higher upfront costs and longer lead times, the potential for increased brand visibility and customer engagement can justify the investment.

Key Industrial Applications of raincoat shoe cover

| Industry/Sector | Specific Application of raincoat shoe cover | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction and Renovation | Protecting footwear from mud and water on job sites | Minimizes cleaning costs and extends shoe lifespan | Durability, size options, and ease of use for workers |

| Food Service | Keeping shoes dry in wet kitchens and during outdoor events | Prevents slip hazards and maintains hygiene standards | Non-slip features, waterproof materials, and compliance with health regulations |

| Agriculture | Shielding shoes from wet conditions while working in fields | Enhances worker comfort and safety in adverse weather | Breathability, fit for different shoe sizes, and resistance to chemicals |

| Environmental Services | Safeguarding footwear while conducting outdoor clean-ups | Protects shoes from contaminants, reducing replacement costs | Eco-friendly materials, waterproofing, and ease of disposal |

| Delivery and Logistics | Ensuring footwear remains dry during outdoor deliveries | Improves employee comfort and reduces risk of accidents | Lightweight design, quick to put on and take off, and compatibility with various shoe types |

How is Raincoat Shoe Cover Used in Construction and Renovation Industries?

In the construction sector, raincoat shoe covers are essential for protecting footwear from mud, water, and debris on job sites. These covers help minimize cleaning costs and prolong the life of expensive footwear. Buyers in this sector should prioritize durability and the availability of various sizes to ensure a proper fit for all workers. Additionally, ease of use is crucial, as workers need to put them on quickly when transitioning between different site conditions.

What Role Does Raincoat Shoe Cover Play in the Food Service Sector?

In the food service industry, raincoat shoe covers are vital for maintaining hygiene and safety standards. They protect shoes from wet environments, especially in kitchens and during outdoor events, reducing slip hazards. Businesses should focus on sourcing non-slip, waterproof materials that comply with health regulations. This ensures that employees remain safe while also upholding the establishment’s hygiene standards.

Why are Raincoat Shoe Covers Important in Agriculture?

Agricultural workers often face wet and muddy conditions that can compromise safety and comfort. Raincoat shoe covers provide a barrier against moisture, allowing workers to perform their tasks without worrying about wet feet. For international buyers, it’s essential to consider the breathability of the material and its fit for various shoe sizes, as well as its resistance to chemicals used in farming.

How Do Environmental Services Benefit from Raincoat Shoe Covers?

Environmental service professionals frequently engage in outdoor clean-up efforts where footwear can be exposed to contaminants and wet conditions. Raincoat shoe covers protect shoes from these elements, reducing replacement costs and enhancing worker comfort. Buyers should look for eco-friendly materials that are waterproof and easy to dispose of, aligning with sustainability goals.

In What Ways Do Delivery and Logistics Use Raincoat Shoe Covers?

In the delivery and logistics sector, raincoat shoe covers ensure that employees’ footwear remains dry during outdoor deliveries, especially in inclement weather. This not only improves comfort but also decreases the risk of accidents due to slippery shoes. When sourcing, businesses should seek lightweight designs that are quick to put on and compatible with various shoe types, ensuring efficiency in operations.

3 Common User Pain Points for ‘raincoat shoe cover’ & Their Solutions

Scenario 1: Concerns Over Durability and Performance in Harsh Conditions

The Problem: B2B buyers, particularly those in industries like construction or outdoor services, often face concerns regarding the durability and performance of raincoat shoe covers. When equipment is exposed to harsh weather conditions, there is a heightened risk that low-quality covers will fail, leading to wet footwear, reduced worker productivity, and potential safety hazards from slipping. These buyers need assurance that their chosen products will withstand rigorous use without compromising on safety or comfort.

The Solution: To ensure the selection of high-quality raincoat shoe covers, buyers should focus on sourcing products made from robust, waterproof materials that are specifically designed for industrial applications. Look for covers with reinforced seams and anti-slip soles to enhance durability and traction. Additionally, requesting samples before making a bulk purchase can help assess the product’s performance in real-world conditions. Buyers should also consider covers that offer a range of sizes to accommodate different footwear, ensuring a snug fit that prevents water ingress. Partnering with reputable suppliers who provide detailed product specifications and performance guarantees can further mitigate risks.

Scenario 2: Difficulty in Sizing and Fit for Diverse Workforces

The Problem: In many workplaces, particularly those with diverse employee sizes and shoe types, finding raincoat shoe covers that fit well across the workforce can be a significant challenge. Ill-fitting covers can lead to discomfort, decreased mobility, and ultimately, lower morale among workers. This issue is especially pronounced in B2B environments where uniformity and professionalism are key to maintaining a cohesive brand image.

The Solution: To address sizing challenges, buyers should prioritize sourcing raincoat shoe covers that are available in a range of sizes or offer adjustable features. Suppliers that provide a comprehensive size chart along with fitting guidelines can help ensure a better fit for all employees. Bulk purchasing options that allow for a mix of sizes can also be beneficial. Another effective approach is to consider covers that feature elastic openings or Velcro straps, which can accommodate a wider variety of shoe sizes while ensuring a secure fit. Regular feedback from employees regarding fit and comfort can also guide future purchases, helping companies optimize their selection process.

Scenario 3: Environmental Impact and Sustainability Concerns

The Problem: As sustainability becomes a priority for businesses worldwide, B2B buyers are increasingly concerned about the environmental impact of disposable raincoat shoe covers. Many products on the market are made from single-use plastics that contribute to landfill waste, contradicting corporate sustainability goals. This concern is particularly relevant for companies looking to enhance their brand reputation and adhere to environmental regulations.

The Solution: To align with sustainability objectives, buyers should consider sourcing biodegradable or reusable raincoat shoe covers made from eco-friendly materials. Engaging with suppliers who specialize in sustainable products can help identify options that meet both functional and environmental standards. Buyers can also explore the possibility of investing in high-quality reusable covers that can be washed and reused multiple times, significantly reducing waste over time. Educating employees on proper care and maintenance of these products will ensure longevity and further diminish environmental impact. Additionally, companies can promote their commitment to sustainability by communicating these practices to clients and stakeholders, enhancing their brand image in the process.

Strategic Material Selection Guide for raincoat shoe cover

What Are the Key Materials for Raincoat Shoe Covers?

When selecting materials for raincoat shoe covers, it is crucial to consider their properties, advantages, and limitations, particularly from a B2B perspective. The following analysis outlines four common materials used in the production of raincoat shoe covers, focusing on their performance characteristics and implications for international buyers.

How Does PVC Perform as a Material for Raincoat Shoe Covers?

Polyvinyl chloride (PVC) is a widely used material for raincoat shoe covers due to its excellent waterproof properties. PVC is resistant to a range of chemicals and provides good durability under various environmental conditions. It can typically withstand temperatures ranging from -10°C to 60°C, making it suitable for diverse climates.

Pros: PVC is relatively inexpensive and easy to manufacture, allowing for cost-effective production. Its flexibility and strength make it a popular choice for disposable shoe covers in industries like construction and food service.

Cons: However, PVC can become brittle over time, especially when exposed to UV light, which may limit its lifespan. Additionally, it is not biodegradable, raising environmental concerns.

Impact on Application: PVC is ideal for applications where exposure to liquids is frequent, but its limitations in extreme temperatures should be considered.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local environmental regulations regarding PVC usage, as well as adherence to ASTM standards for safety.

Why Choose EVA for Raincoat Shoe Covers?

Ethylene-vinyl acetate (EVA) is another popular choice for raincoat shoe covers, known for its lightweight and flexible nature. EVA offers good resistance to UV radiation and is more durable than PVC, maintaining its integrity under varying temperatures.

Pros: The material is comfortable to wear, making it suitable for longer use. EVA is also less harmful to the environment compared to PVC, as it is easier to recycle.

Cons: The primary downside is that EVA can be more expensive than PVC, which may deter some buyers focused on cost.

Impact on Application: EVA’s flexibility and durability make it suitable for outdoor activities and environments where comfort is crucial.

Considerations for International Buyers: Buyers from Europe may prefer EVA due to its eco-friendliness and compliance with EU regulations on materials. Understanding local preferences can enhance marketability.

What Role Does Polypropylene Play in Raincoat Shoe Covers?

Polypropylene is a thermoplastic polymer that offers excellent moisture resistance and is often used in disposable shoe covers. Its lightweight nature and strong chemical resistance make it a viable option for various industries.

Pros: Polypropylene is cost-effective and provides good barrier protection against liquids. It is also resistant to mold and mildew, making it suitable for humid environments.

Cons: However, polypropylene lacks the flexibility of PVC and EVA, which may limit comfort during extended wear. It can also be less durable in extreme temperatures.

Impact on Application: This material is well-suited for short-term use in environments where shoe protection is necessary but comfort is less of a priority.

Considerations for International Buyers: Buyers should verify that polypropylene products meet local safety standards, particularly in industries like healthcare and food service.

How Does Neoprene Compare for Raincoat Shoe Covers?

Neoprene is a synthetic rubber known for its excellent waterproof properties and durability. It can withstand a wide range of temperatures, making it suitable for various climates.

Pros: Neoprene provides superior insulation and comfort, making it ideal for outdoor activities. Its durability ensures a longer lifespan compared to other materials.

Cons: The main drawback is its higher cost, which may not be feasible for all buyers. Additionally, neoprene can be heavier than other materials, potentially impacting ease of use.

Impact on Application: Neoprene is particularly effective in environments where both waterproofing and insulation are required, such as in colder climates.

Considerations for International Buyers: Buyers in colder regions may prioritize neoprene for its thermal properties, while ensuring compliance with local material standards.

Summary Table of Material Selection for Raincoat Shoe Covers

| Material | Typical Use Case for Raincoat Shoe Cover | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Disposable shoe covers in construction | Cost-effective and durable | Brittle over time, not biodegradable | Low |

| EVA | Comfortable covers for outdoor activities | Lightweight and eco-friendly | Higher cost | Med |

| Polypropylene | Short-term use in healthcare | Good barrier protection | Less flexible, lower durability | Low |

| Neoprene | Insulated covers for cold climates | Superior waterproofing and comfort | Higher cost, heavier | High |

This strategic material selection guide provides insights for B2B buyers looking to make informed decisions on raincoat shoe covers, considering performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for raincoat shoe cover

What Are the Key Stages in the Manufacturing Process of Raincoat Shoe Covers?

The manufacturing process of raincoat shoe covers encompasses several critical stages: material preparation, forming, assembly, and finishing. Understanding these stages is vital for B2B buyers looking to ensure quality and consistency in the products they procure.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step involves sourcing high-quality raw materials, typically waterproof fabrics such as PVC, polyethylene, or rubber blends. These materials are chosen for their durability and water-resistant properties. Once sourced, the materials undergo a thorough quality check to ensure they meet specific industry standards. This stage often includes cutting the materials into predetermined sizes and shapes, which is essential for uniformity in the final product.

Forming: What Techniques Are Used to Shape the Shoe Covers?

The forming stage involves techniques such as heat sealing, sewing, or molding, depending on the design and material used. Heat sealing is particularly common for waterproof shoe covers, as it creates strong, watertight seams. In contrast, sewn covers may offer more flexibility in design but could require additional waterproofing treatments. Advanced manufacturers may also employ ultrasonic welding for seamless constructions, enhancing the waterproofing capabilities of the shoe covers.

Assembly: How Are the Components Brought Together?

In the assembly phase, various components such as straps, Velcro fasteners, and elastic bands are added to the base material. This stage is crucial for ensuring that the shoe covers are easy to wear and provide a secure fit. Quality assurance checks are often integrated into this phase to monitor the assembly process, ensuring that all components meet the specified design criteria.

Finishing: What Final Touches Are Applied to Ensure Quality?

The finishing stage includes processes such as trimming excess material, applying branding, and conducting final inspections. Manufacturers may also treat the covers with additional coatings to enhance water resistance or durability. This stage ensures that the product is visually appealing and functional, ready for packaging and distribution.

What International Standards Govern Quality Assurance in Raincoat Shoe Covers?

Quality assurance is paramount in the manufacturing of raincoat shoe covers, especially for international B2B buyers who require reliable and compliant products. Several international standards and industry-specific certifications guide manufacturers in maintaining quality.

What Are the Relevant International Quality Standards?

ISO 9001 is the most recognized quality management standard, focusing on ensuring consistent quality in products and services. Manufacturers that comply with ISO 9001 demonstrate their ability to meet customer and regulatory requirements effectively. Additionally, certifications such as CE mark are critical for products sold in the European market, indicating compliance with health, safety, and environmental protection standards.

How Are Quality Control Checkpoints Established?

Quality control (QC) checkpoints are integral to the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages helps identify and rectify issues in real-time.

- Final Quality Control (FQC): A thorough inspection of the finished product ensures that it meets all quality standards before shipping.

What Common Testing Methods Are Employed for Quality Assurance?

Manufacturers utilize various testing methods to ensure the functionality and durability of raincoat shoe covers:

- Waterproof Testing: This assesses the product’s ability to withstand water exposure.

- Tensile Strength Testing: Evaluates the durability and resistance to tearing.

- Flexibility Testing: Ensures that the material retains its properties under movement and stress.

- Chemical Resistance Testing: For materials that may come into contact with harsh substances, this testing is essential.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control practices is crucial to ensure product reliability. Here are several strategies to achieve this:

What Audit Processes Should Buyers Consider?

Conducting supplier audits is an effective way to assess quality control measures. Buyers can request documentation of quality management systems, including ISO certifications and internal QC reports. Engaging third-party auditors can also provide an unbiased evaluation of a manufacturer’s compliance with international standards.

How Can Buyers Leverage Testing Reports?

Buyers should request detailed testing reports from suppliers, including results from the aforementioned testing methods. These reports should provide insights into the product’s performance, highlighting any areas of concern or non-compliance.

What Nuances Should International B2B Buyers Be Aware Of?

International B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances that may affect their procurement processes:

- Import Regulations: Each region may have distinct import regulations and standards that need to be met. Understanding these requirements is essential to avoid costly delays or penalties.

- Cultural Differences: Communication styles and business practices can vary significantly across cultures. Establishing clear and open lines of communication can help bridge these gaps and facilitate smoother transactions.

- Logistics and Supply Chain Considerations: Buyers should consider the logistics involved in shipping products internationally, including tariffs, shipping times, and potential customs issues.

Conclusion: Why Is Understanding Manufacturing Processes and Quality Assurance Essential for B2B Buyers?

For international B2B buyers, a comprehensive understanding of the manufacturing processes and quality assurance practices for raincoat shoe covers is crucial. This knowledge not only aids in selecting reliable suppliers but also ensures that the products meet the necessary standards for durability and functionality in diverse environmental conditions. By leveraging this insight, buyers can make informed decisions that align with their operational needs and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘raincoat shoe cover’

In today’s global market, sourcing quality raincoat shoe covers is essential for businesses that require protection against wet conditions. This guide provides a step-by-step checklist to help international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, procure the right products effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital to ensure that the raincoat shoe covers meet your operational needs. Consider factors such as material durability, waterproofing capabilities, and size variations. For instance, if your workforce includes individuals with varying shoe sizes, opt for products labeled as “one size fits all” or those that offer multiple sizes.

Step 2: Research Market Trends and Compliance Standards

Understanding market trends and compliance standards is crucial for informed purchasing decisions. Research the latest innovations in waterproof materials and design features that enhance usability. Additionally, verify if the products meet local safety and environmental regulations in your target market, as this can affect your brand’s reputation and legal compliance.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request detailed company profiles, including their experience in the industry and past client references, particularly from businesses similar to yours. Assess their certifications, such as ISO, to ensure quality assurance and reliability in their products.

Step 4: Request Samples for Quality Assessment

Once you have shortlisted potential suppliers, request samples of the raincoat shoe covers. This step allows you to assess the quality, fit, and functionality of the products firsthand. Pay close attention to the material’s waterproofing ability, ease of use, and overall comfort, as these factors will impact user satisfaction.

Step 5: Compare Pricing and Bulk Order Discounts

Pricing can vary significantly between suppliers, so it is essential to compare quotes. Look for bulk order discounts that can help reduce your overall costs. Consider the total cost of ownership, including shipping and potential duties, to ensure you are making a financially sound decision.

Step 6: Negotiate Terms and Conditions

Engage in discussions with your chosen supplier to negotiate favorable terms and conditions. Key aspects to cover include payment terms, lead times, and return policies. Establishing clear agreements upfront can help prevent misunderstandings and protect your interests in the long run.

Step 7: Implement a Quality Control Process

Once you’ve placed your order, it’s important to implement a quality control process upon receipt. Inspect the products to ensure they meet the agreed-upon specifications and standards. Establishing a robust quality assurance process will help maintain consistency and reliability in your supply chain.

By following this practical sourcing guide, B2B buyers can effectively navigate the procurement process for raincoat shoe covers, ensuring they secure high-quality products that meet their specific business needs.

Comprehensive Cost and Pricing Analysis for raincoat shoe cover Sourcing

What Are the Key Cost Components for Sourcing Raincoat Shoe Covers?

When considering the sourcing of raincoat shoe covers, it’s essential to analyze the underlying cost structure, which typically includes materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and desired profit margins.

-

Materials: The choice of materials significantly affects the cost. High-quality waterproof fabrics, such as polyethylene and Tyvek, provide durability but may increase the per-unit cost. Buyers should evaluate the trade-off between material quality and price to meet their specific market demands.

-

Labor and Manufacturing Overhead: Labor costs can vary based on the production location, with countries in Asia generally offering lower labor costs compared to those in Europe or North America. Manufacturing overhead includes costs related to utilities, factory maintenance, and administrative expenses, which also fluctuate based on geographical factors.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. Buyers should consider whether standard sizes are sufficient or if unique specifications will necessitate additional investments in tooling.

-

Quality Control (QC): Implementing a robust QC process is crucial to ensure product reliability. This may involve additional costs, but it can prevent costly returns and enhance customer satisfaction.

-

Logistics: Shipping costs are influenced by the size of the order and the destination. International shipping, customs duties, and tariffs can add significant expenses, particularly for buyers in regions like Africa and South America.

-

Margin: Suppliers typically add a profit margin to cover their risks and operational costs. Understanding the average margins in the industry can help buyers negotiate better deals.

How Do Price Influencers Impact Raincoat Shoe Cover Sourcing?

Several factors influence the pricing of raincoat shoe covers, making it crucial for buyers to understand these variables:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Bulk purchases often lead to reduced per-unit costs, so planning for larger orders can enhance cost-efficiency.

-

Specifications and Customization: Custom designs or specific features (e.g., reflective strips or unique sizing) can increase costs. Buyers should clearly define their needs to avoid unnecessary expenses.

-

Materials and Certifications: The quality of materials directly correlates with price. Additionally, certifications (such as ISO or CE) may be required for compliance in certain markets, adding to the overall cost.

-

Supplier Factors: The supplier’s reliability, reputation, and geographical location can influence pricing. It is advisable to work with established suppliers who offer competitive pricing and quality assurance.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) affect shipping costs and responsibilities. Understanding these terms can help buyers manage logistics expenses effectively.

What Are the Best Practices for Negotiating Raincoat Shoe Cover Prices?

For international B2B buyers, especially in regions like Africa, South America, and the Middle East, effective negotiation strategies are vital for optimizing costs:

-

Research and Benchmarking: Conduct thorough market research to understand average pricing and identify competitive offers. This knowledge empowers buyers during negotiations.

-

Leverage Volume Discounts: Use the potential for larger orders as a bargaining chip. Suppliers are often willing to negotiate better rates for bulk purchases.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with the product, including maintenance, potential returns, and logistics.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations and economic conditions that may affect pricing. Agreeing on fixed pricing or currency can mitigate risks.

-

Build Strong Relationships: Establishing a rapport with suppliers can lead to better terms and flexibility in negotiations. Long-term partnerships often yield mutual benefits.

Conclusion

Understanding the comprehensive cost structure and pricing dynamics of raincoat shoe covers is crucial for effective sourcing. By focusing on the key cost components, price influencers, and negotiation strategies, B2B buyers can make informed decisions that enhance their supply chain efficiency and profitability. Always remember that prices can vary significantly based on factors such as location, material quality, and order size, so maintaining flexibility and adaptability in sourcing strategies is essential.

Alternatives Analysis: Comparing raincoat shoe cover With Other Solutions

In the pursuit of effective footwear protection during inclement weather, businesses often find themselves evaluating various solutions. While raincoat shoe covers are a popular choice, there are several alternative methods that can also serve to keep shoes dry and maintain hygiene in wet conditions. This analysis will compare raincoat shoe covers with two viable alternatives: waterproof shoe covers and disposable shoe covers.

| Comparison Aspect | Raincoat Shoe Cover | Waterproof Shoe Covers | Disposable Shoe Covers |

|---|---|---|---|

| Performance | Excellent water resistance; protects shoes from mud and water | High durability; protects shoes and lower legs | Basic protection; suitable for short-term use |

| Cost | Moderate initial investment | Varies widely; often higher for durable options | Low cost; suitable for bulk purchasing |

| Ease of Implementation | Easy to wear and remove | Slightly more complex; may require adjustments | Very easy; single-use and no setup needed |

| Maintenance | Requires cleaning and drying | Can be reused but needs washing | No maintenance; simply dispose after use |

| Best Use Case | Ideal for cycling and outdoor activities | Best for construction and wet environments | Suitable for temporary use in clean environments |

What Are the Advantages and Disadvantages of Waterproof Shoe Covers?

Waterproof shoe covers are designed to provide robust protection against water and mud. They typically come in various sizes and materials, allowing for a snug fit on different footwear. Their durability makes them suitable for extended use in demanding environments like construction sites. However, they may require washing and maintenance, which can be a drawback for companies looking for hassle-free solutions.

How Do Disposable Shoe Covers Compare?

Disposable shoe covers offer a straightforward solution for protecting shoes in environments where cleanliness is a priority, such as healthcare facilities or during cleanroom operations. These covers are typically made from lightweight materials, making them easy to slip on and off. Their cost-effectiveness makes them appealing for businesses that require bulk purchasing. However, they provide limited protection against heavy rain or mud, making them less suitable for outdoor activities.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate footwear protection solution, B2B buyers should consider the specific needs of their operations. For businesses involved in outdoor activities or cycling, raincoat shoe covers may be the best option due to their superior water resistance and comfort. Conversely, for industries that prioritize cleanliness and require frequent shoe changes, disposable shoe covers might be more efficient. Waterproof shoe covers strike a balance between durability and performance, making them a versatile choice for various environments. Ultimately, understanding the unique requirements of your operational context will guide you in making the most informed decision.

Essential Technical Properties and Trade Terminology for raincoat shoe cover

What Are the Key Technical Properties of Raincoat Shoe Covers?

When sourcing raincoat shoe covers for industrial or commercial use, understanding their technical properties is essential for making informed purchasing decisions. Here are several critical specifications to consider:

-

Material Grade

The most common materials used for raincoat shoe covers include polyethylene (PE), polypropylene (PP), and thermoplastic elastomers (TPE). Each material has its own properties, such as durability, flexibility, and waterproof capabilities. For example, TPE offers excellent stretchability and comfort, making it ideal for prolonged use, while PE is often favored for its cost-effectiveness and basic waterproof features. Understanding the material grade helps buyers assess the suitability of the covers for specific applications, such as construction, food service, or outdoor activities. -

Water Resistance Rating

This property indicates the effectiveness of the shoe covers in repelling water. A higher water resistance rating generally means better protection against moisture. Buyers should look for covers with ratings such as ASTM F1671, which tests for resistance to penetration by blood and bodily fluids, indicating high-level waterproofing. This is particularly important in industries such as healthcare and food processing, where exposure to liquids is common. -

Size and Fit Specifications

Most manufacturers offer shoe covers in various sizes or as “one size fits all.” However, ensuring the correct fit is crucial for both comfort and functionality. Poorly fitting covers can slip off or allow water ingress, negating their protective purpose. Buyers should verify the dimensions and design specifications, including elastic bands or adjustable straps, to ensure they meet the needs of their workforce. -

Weight and Portability

Lightweight designs are often preferred for ease of use and storage. A shoe cover that is easy to put on and take off can significantly enhance productivity, especially in dynamic work environments. Additionally, the weight affects shipping costs and logistics. Buyers should consider bulk purchasing options that balance cost and convenience. -

Durability and Reusability

The expected lifespan of the shoe covers can influence purchasing decisions. Disposable covers may be cheaper initially but can lead to higher long-term costs if frequent replacements are needed. On the other hand, reusable options may require a higher upfront investment but can offer better value over time, especially in high-usage scenarios.

What Are Common Trade Terms Related to Raincoat Shoe Covers?

Familiarity with trade terminology can facilitate smoother transactions and negotiations in the B2B marketplace. Here are some essential terms to know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of raincoat shoe covers, an OEM may supply customized designs or proprietary materials to brands that then sell them under their label. Understanding OEM relationships can help buyers identify potential suppliers and assess product authenticity. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers as it impacts initial investment and inventory management. Knowing the MOQ can help businesses plan their purchasing strategy and budget accordingly. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request price quotes for specific products or services. For raincoat shoe covers, an RFQ should detail specifications such as material, size, and quantity, enabling suppliers to provide accurate pricing. This process is vital for comparing costs and ensuring competitive pricing. -

Incoterms (International Commercial Terms)

These are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). Understanding Incoterms helps buyers clarify shipping arrangements and liabilities, ensuring smoother logistics. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the products. This term is critical for planning purposes, especially for businesses that require timely delivery of raincoat shoe covers to meet operational demands. Knowing the expected lead time can help buyers manage inventory and avoid disruptions.

By understanding these technical properties and trade terms, B2B buyers can make more informed purchasing decisions and foster better supplier relationships in the market for raincoat shoe covers.

Navigating Market Dynamics and Sourcing Trends in the raincoat shoe cover Sector

What Are the Key Market Trends Affecting Raincoat Shoe Covers Globally?

The raincoat shoe cover market is currently experiencing a surge in demand, driven by several global factors. Increased awareness of environmental issues, coupled with the rise of outdoor activities and urban commuting, has accelerated the need for effective waterproof solutions. In regions such as Africa, South America, the Middle East, and Europe, the demand is further propelled by urbanization and changing weather patterns, which have made reliable waterproof gear a necessity.

Emerging B2B technology trends are also reshaping the sourcing landscape. Online platforms and marketplaces are facilitating easier access to a wider array of products, enabling buyers to compare prices, quality, and supplier reliability with unprecedented efficiency. Additionally, advancements in materials science are leading to the development of lighter, more durable, and eco-friendly materials, which are crucial for meeting both consumer expectations and regulatory standards.

International buyers should also be aware of the shift toward direct sourcing from manufacturers. This trend is particularly relevant in regions like Nigeria and Vietnam, where local production capabilities are expanding. By sourcing directly, businesses can benefit from reduced costs and improved supply chain transparency, allowing for better inventory management and quicker response times to market demands.

How Is Sustainability Influencing the Sourcing of Raincoat Shoe Covers?

Sustainability has become a cornerstone of sourcing practices in the raincoat shoe cover sector. Environmental concerns have prompted buyers to prioritize suppliers who demonstrate a commitment to ethical sourcing and sustainability. This includes using recyclable or biodegradable materials, reducing waste in production processes, and ensuring fair labor practices throughout the supply chain.

Buyers should look for certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX, which indicate adherence to environmental and social standards. Furthermore, the increasing consumer preference for sustainable products is encouraging brands to invest in green technologies and materials. For example, shoe covers made from recycled plastics or organic cotton not only minimize environmental impact but also appeal to eco-conscious consumers.

Establishing partnerships with suppliers who prioritize sustainability can enhance a company’s brand reputation and open up new market opportunities, particularly in regions where consumers are increasingly valuing ethical practices. As the market evolves, B2B buyers must stay informed about sustainability trends to ensure they align with both consumer expectations and regulatory requirements.

What Is the Historical Context of Raincoat Shoe Covers in B2B Markets?

The raincoat shoe cover has evolved significantly over the decades, transitioning from basic protective gear to a specialized product designed for various applications. Initially popularized in industrial sectors, such as construction and cleaning, shoe covers have now found a broader audience, including outdoor enthusiasts and urban commuters.

Historically, the materials used in raincoat shoe covers were primarily limited to basic waterproof plastics. However, advancements in technology have led to the introduction of lightweight, breathable, and eco-friendly materials, thus enhancing comfort and functionality. This evolution reflects changing consumer expectations and the growing importance of both performance and sustainability in product design.

As the market continues to mature, understanding the historical context of raincoat shoe covers can provide valuable insights into current trends and future opportunities, particularly for B2B buyers looking to navigate this dynamic sector.

Frequently Asked Questions (FAQs) for B2B Buyers of raincoat shoe cover

-

How do I ensure the quality of raincoat shoe covers before purchasing?

To ensure quality, request samples from potential suppliers to assess material durability and waterproof capabilities. Verify certifications, such as ISO or ASTM, that indicate compliance with industry standards. Additionally, inquire about the supplier’s quality assurance processes, including inspections and testing methods. Reviews and testimonials from other B2B buyers can also provide insights into the reliability of the products. Consider visiting the manufacturing facility if feasible, as this can give you a firsthand look at their production practices. -

What factors should I consider when selecting a supplier for raincoat shoe covers?

When selecting a supplier, evaluate their experience in the industry, production capacity, and delivery timelines. It’s essential to assess their compliance with international trade regulations, especially if importing to regions like Africa or South America. Check for customer service responsiveness, as effective communication is crucial in B2B transactions. Furthermore, consider their ability to customize products to meet specific needs, such as size variations or branding options, which can enhance your product offering. -

What is the minimum order quantity (MOQ) for raincoat shoe covers?

Minimum order quantities can vary significantly among suppliers. Typically, MOQs for raincoat shoe covers can range from 100 to 1,000 units, depending on the materials and customization options. It is advisable to clarify MOQs during initial discussions and negotiate if necessary. Some suppliers may offer lower MOQs for first-time orders or samples, which can be beneficial for testing the market before committing to larger quantities. -

How can I customize raincoat shoe covers for my brand?

Customization options often include size adjustments, color selections, and branding through logos or designs. To initiate customization, communicate your specific requirements to the supplier and request a prototype. Some manufacturers may have limitations on customization, so it’s important to discuss these details upfront. Ensure that the customization aligns with your target market preferences, as this can significantly enhance brand recognition and customer loyalty. -

What payment terms are typically offered by suppliers of raincoat shoe covers?

Payment terms can vary, but many suppliers offer options such as advance payment, partial payment upon order confirmation, and balance upon delivery. Common methods include bank transfers, letters of credit, or payment platforms like PayPal. Discuss and negotiate terms that suit your cash flow needs while ensuring security for both parties. Be cautious of suppliers demanding full payment upfront, as this can increase risk, especially with unfamiliar vendors. -

What logistics considerations should I be aware of when importing raincoat shoe covers?

Logistics plays a vital role in the timely delivery of your order. Assess shipping options, including air freight for faster delivery or sea freight for cost-effectiveness. Understand the customs regulations for your country, as they can impact delivery timelines and costs. Work with a freight forwarder who can guide you through the import process, including duties, tariffs, and documentation requirements, ensuring compliance and minimizing delays. -

How do I handle disputes with suppliers of raincoat shoe covers?

To handle disputes effectively, maintain clear communication with your supplier and document all interactions. If issues arise, attempt to resolve them amicably by discussing the problem and seeking mutually beneficial solutions. Refer to your contract for terms related to disputes, including any arbitration clauses. If resolution fails, consider involving a third-party mediator or legal counsel, especially for significant transactions, to protect your interests. -

What are the best practices for storing raincoat shoe covers in my warehouse?

Proper storage is crucial to maintaining the quality of raincoat shoe covers. Store them in a cool, dry environment to prevent degradation from humidity or extreme temperatures. Utilize shelves to keep products off the floor and away from direct sunlight, which can cause fading and material breakdown. Regularly inspect inventory for signs of damage or wear, and rotate stock to ensure older products are sold first, minimizing losses from unsold inventory.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Raincoat Shoe Cover Manufacturers & Suppliers List

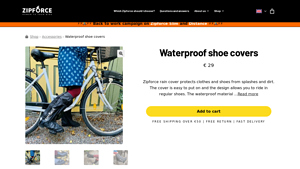

1. Zipforce – Waterproof Shoe Covers

Domain: zipforce.io

Registered: 2022 (3 years)

Introduction: Waterproof shoe covers from Zipforce, priced at €29. Designed to protect clothes and shoes from splashes and dirt, these covers are easy to put on and allow riding in regular shoes. Made from waterproof material, they protect shoes and lower legs up to the knee. The covers fasten around the legs with Velcro and are secured with a strap under the shoes. They do not have their own sole, preventing d…

2. Target – Waterproof Rain Shoe Covers and Boots

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Waterproof Rain Shoe Covers and Boots, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

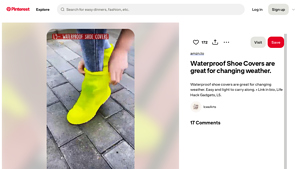

3. SooGree – Waterproof Rain Boot Covers

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: SooGree Rain Boot Covers, Waterproof Rain Shoe Covers, Silicone Shoe Protector, Overshoes, Sand Control, Non-Slip, Foldable, Reusable, Galoshes for Men and Women, suitable for rainy outdoor conditions.

Strategic Sourcing Conclusion and Outlook for raincoat shoe cover

In the evolving landscape of raincoat shoe covers, strategic sourcing emerges as a critical component for B2B buyers aiming to optimize procurement and enhance product offerings. By understanding market trends, such as the increasing demand for waterproof and durable materials, buyers can make informed decisions that align with their business goals. The variety of options available—from lightweight, disposable covers to robust, reusable solutions—allows companies to cater to diverse customer needs across different sectors, including construction, food service, and outdoor activities.

Investing in quality raincoat shoe covers not only protects footwear but also reinforces brand integrity by ensuring customer satisfaction. As international markets grow, particularly in Africa, South America, the Middle East, and Europe, buyers should leverage local insights and supplier partnerships to navigate regional preferences effectively.

Looking ahead, the raincoat shoe cover market is poised for innovation, driven by advancements in materials and design. B2B buyers are encouraged to explore new sourcing opportunities, engage with suppliers proactively, and stay ahead of market shifts. By prioritizing strategic sourcing, businesses can enhance their competitive edge and meet the evolving demands of their clientele. Take the next step in your procurement strategy today to secure your position in this dynamic market.