Introduction: Navigating the Global Market for raincoat shoe cover

In the unpredictable world of weather, sourcing high-quality raincoat shoe covers can be a significant challenge for international B2B buyers. Businesses across various sectors—from construction to food service—require reliable protection for footwear against moisture and dirt, ensuring that their workforce remains safe and presentable in inclement conditions. This comprehensive guide delves into the diverse types of raincoat shoe covers available in the global market, their specific applications, and the critical factors to consider when vetting suppliers.

Understanding the nuances of this product category is essential for informed purchasing decisions. This guide will empower B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Saudi Arabia—by providing insights on material quality, pricing structures, and vendor reliability. By exploring the latest trends and innovations in raincoat shoe covers, businesses can align their procurement strategies with market demands, ensuring they select products that not only meet their operational needs but also enhance their brand reputation.

As you navigate the complexities of sourcing raincoat shoe covers, this guide serves as your invaluable resource, enabling you to make strategic decisions that drive success in your business endeavors.

Article Navigation

- Top 2 Raincoat Shoe Cover Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for raincoat shoe cover

- Understanding raincoat shoe cover Types and Variations

- Key Industrial Applications of raincoat shoe cover

- 3 Common User Pain Points for ‘raincoat shoe cover’ & Their Solutions

- Strategic Material Selection Guide for raincoat shoe cover

- In-depth Look: Manufacturing Processes and Quality Assurance for raincoat shoe cover

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘raincoat shoe cover’

- Comprehensive Cost and Pricing Analysis for raincoat shoe cover Sourcing

- Alternatives Analysis: Comparing raincoat shoe cover With Other Solutions

- Essential Technical Properties and Trade Terminology for raincoat shoe cover

- Navigating Market Dynamics and Sourcing Trends in the raincoat shoe cover Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of raincoat shoe cover

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for raincoat shoe cover

Understanding raincoat shoe cover Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Disposable Shoe Covers | Lightweight, single-use, often made from polyethylene | Construction, cleaning, food service | Pros: Cost-effective, hygienic; Cons: Not reusable, may tear easily. |

| Reusable Waterproof Covers | Durable materials, often machine washable | Outdoor events, cycling, maintenance | Pros: Eco-friendly, cost-saving over time; Cons: Higher upfront cost, requires care. |

| Heavy-Duty Boot Covers | Reinforced materials, designed for rugged use | Industrial, manufacturing, hazardous work | Pros: Superior protection, long-lasting; Cons: Bulkier, may be less comfortable. |

| High-Traction Shoe Covers | Non-slip soles, designed for wet conditions | Hospitality, healthcare, outdoor activities | Pros: Enhanced safety, reliable grip; Cons: Higher price, may not fit all shoe types. |

| Fashionable Rain Shoe Covers | Stylish designs, available in various colors | Retail, promotional events | Pros: Aesthetically pleasing, brand visibility; Cons: Less functional, can be more expensive. |

What Are the Key Characteristics of Disposable Shoe Covers?

Disposable shoe covers are primarily made from lightweight polyethylene, making them a popular choice for businesses seeking a cost-effective solution for protecting footwear. They are designed for single use, which enhances hygiene in environments such as construction sites, cleaning services, and food preparation areas. Buyers should consider the volume of usage, as these covers can quickly accumulate costs if used frequently. Their lightweight nature facilitates easy storage and transport, though they may tear easily under stress.

How Do Reusable Waterproof Covers Stand Out?

Reusable waterproof covers are crafted from durable, high-quality materials that can withstand repeated use and are often machine washable. These covers are ideal for outdoor events, cycling, and maintenance applications where protection from water and mud is essential. B2B buyers should focus on the long-term cost benefits, as these covers can save money over time compared to disposable options. However, the initial investment is higher, and they require proper care and maintenance to ensure longevity.

What Makes Heavy-Duty Boot Covers Essential for Industrial Applications?

Heavy-duty boot covers are constructed from reinforced materials, providing exceptional protection in rugged environments such as industrial and manufacturing settings. They are designed to withstand harsh conditions and are ideal for jobs involving hazardous materials. Buyers in these sectors should evaluate the level of protection needed, as these covers offer superior durability. However, their bulkiness may compromise comfort, and they might not be suitable for all work environments.

Why Choose High-Traction Shoe Covers for Safety?

High-traction shoe covers feature non-slip soles that provide enhanced safety in wet or slippery conditions, making them a smart choice for industries such as hospitality and healthcare. These covers are designed to prevent slips and falls, thereby reducing workplace accidents. When considering a purchase, businesses should weigh the importance of safety against the higher price point. While they may not fit all shoe types, their functionality in critical environments can justify the investment.

How Do Fashionable Rain Shoe Covers Enhance Brand Visibility?

Fashionable rain shoe covers are available in various stylish designs and colors, making them suitable for retail and promotional events. They provide a unique opportunity for businesses to enhance their brand visibility while offering protection against rain. Buyers should consider the aesthetics and branding potential, recognizing that while they may be less functional than other types, their appeal can attract customer attention. However, the cost may be higher, and their protective capabilities might not match those of more utilitarian options.

Key Industrial Applications of raincoat shoe cover

| Industry/Sector | Specific Application of raincoat shoe cover | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | On-site worker protection during rain | Minimizes downtime and protects footwear from moisture | Durability, slip resistance, and ease of use are critical factors. |

| Food Service | Preventing contamination in wet conditions | Ensures hygiene and protects staff footwear | Compliance with health regulations and ease of cleaning are vital. |

| Healthcare | Maintaining cleanliness in patient areas | Reduces cross-contamination risks | Must be non-slip and easily disposable for safety and convenience. |

| Agriculture | Protecting shoes during fieldwork | Enhances worker comfort and safety in wet environments | Weather resistance and fit are essential for diverse terrains. |

| Transportation | Safeguarding footwear in inclement weather | Enhances employee professionalism and safety | Lightweight and waterproof materials are preferred for mobility. |

How are Raincoat Shoe Covers Used in Construction and What Problems Do They Solve?

In the construction industry, raincoat shoe covers are essential for protecting workers’ footwear from wet and muddy conditions. These covers help to minimize downtime caused by weather-related delays, ensuring that workers can continue their tasks without the inconvenience of wet shoes. For international buyers, sourcing durable and slip-resistant covers that can withstand rigorous site conditions is crucial. Buyers should also consider the ease of putting on and removing these covers, as quick transitions can enhance productivity on-site.

What Role Do Raincoat Shoe Covers Play in Food Service?

In food service, raincoat shoe covers are vital for maintaining hygiene, especially when staff must navigate wet areas or deal with liquids. These covers prevent contamination of food preparation areas, ensuring compliance with health regulations. Businesses in this sector should prioritize sourcing covers that are easy to clean and disposable, as maintaining high hygiene standards is critical. Additionally, the covers should provide a secure fit to prevent slips and falls, which can lead to accidents and liability issues.

How Do Raincoat Shoe Covers Enhance Safety in Healthcare Settings?

In healthcare environments, raincoat shoe covers help maintain cleanliness in patient care areas by reducing the risk of cross-contamination. They are particularly useful when staff need to enter wet environments or during inclement weather. Buyers in this sector should focus on sourcing covers that are non-slip and easily disposable to ensure safety and convenience. Compliance with healthcare standards is paramount, and the covers must also allow for quick donning and removal to facilitate efficient workflows.

Why are Raincoat Shoe Covers Important in Agriculture?

Agricultural workers frequently operate in wet and muddy conditions, making raincoat shoe covers indispensable for protecting footwear and enhancing comfort. These covers allow workers to focus on their tasks without the distraction of wet shoes, which can lead to discomfort and decreased productivity. For international buyers, sourcing covers that are weather-resistant and provide a good fit for various terrains is essential. The ability to withstand harsh conditions while remaining lightweight can significantly improve worker morale and safety.

What Benefits Do Raincoat Shoe Covers Provide in Transportation?

In the transportation sector, raincoat shoe covers are used to safeguard employee footwear from rain and mud, maintaining a professional appearance. These covers enhance safety by providing non-slip protection while employees navigate wet surfaces. Buyers in this sector should prioritize sourcing lightweight and waterproof materials to ensure ease of movement. Additionally, covers that are easy to store and transport can be a significant advantage for businesses operating in regions with unpredictable weather patterns.

3 Common User Pain Points for ‘raincoat shoe cover’ & Their Solutions

Scenario 1: Difficulty in Sizing and Fit for Diverse Workforce

The Problem: One of the most common challenges faced by B2B buyers of raincoat shoe covers is ensuring that the product fits a diverse workforce. In industries such as construction, agriculture, and food service, employees may have varying shoe sizes and types. This variability can lead to dissatisfaction among employees if the shoe covers are too tight, too loose, or incompatible with their footwear. Moreover, inadequate fit can compromise the effectiveness of the cover, leading to wet shoes and potential health issues for workers.

The Solution: To address sizing concerns, buyers should prioritize sourcing raincoat shoe covers that offer a range of sizes or come in a flexible, one-size-fits-all design. When evaluating suppliers, request detailed sizing charts and consider models with adjustable features, such as elastic bands or Velcro fasteners. This adaptability ensures a snug fit for various shoe types and sizes. Additionally, conducting a pilot program with a sample group can help gauge the effectiveness and comfort of the shoe covers before making a bulk purchase. This step not only enhances employee satisfaction but also reduces the likelihood of returns or exchanges, saving time and costs.

Scenario 2: Insufficient Durability Under Harsh Conditions

The Problem: Another significant pain point for B2B buyers is the durability of raincoat shoe covers in demanding environments. For instance, workers in construction or outdoor maintenance may encounter rough terrains, sharp objects, or prolonged exposure to water, which can quickly degrade inferior-quality covers. This situation can lead to increased replacement costs and worker downtime due to inadequate protection, negatively impacting productivity.

The Solution: Buyers should focus on sourcing high-quality, heavy-duty raincoat shoe covers made from robust materials such as polyethylene or TPU (thermoplastic polyurethane). These materials offer better resistance to punctures and tears, ensuring longevity even in challenging work conditions. It’s advisable to request product samples and conduct field tests to evaluate performance before making a large order. Additionally, consider establishing a relationship with suppliers who offer warranties or guarantees on their products, as this indicates confidence in their durability and can provide peace of mind for your purchasing decisions.

Scenario 3: Limited Availability of Waterproof Features

The Problem: Many B2B buyers face challenges when raincoat shoe covers fail to provide adequate waterproofing, especially in industries where workers are exposed to wet environments for extended periods. Insufficient waterproof features can lead to employee discomfort and potential slips or falls, resulting in safety hazards and liability issues for companies.

The Solution: To ensure effective waterproofing, buyers should look for shoe covers specifically marketed as “100% waterproof” and examine the construction techniques used. Seam-sealing and water-resistant zippers can significantly enhance the cover’s protective capabilities. Additionally, consider sourcing products that feature breathable materials to prevent moisture buildup inside the cover, which can lead to discomfort. It’s beneficial to consult with suppliers about their testing procedures for waterproof claims, and to request certifications or independent test results that validate the product’s performance. Engaging in thorough due diligence will help in selecting the best options that guarantee safety and comfort for employees working in wet conditions.

By addressing these common pain points with actionable solutions, B2B buyers can enhance their procurement processes, ensuring that their workforce remains protected and efficient in all weather conditions.

Strategic Material Selection Guide for raincoat shoe cover

What Are the Key Materials Used in Raincoat Shoe Covers?

When selecting materials for raincoat shoe covers, it is essential to consider properties that impact performance, durability, and overall suitability for various applications. Here, we analyze four common materials used in the manufacturing of raincoat shoe covers, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does PVC Perform in Raincoat Shoe Covers?

Polyvinyl Chloride (PVC) is a widely used material for raincoat shoe covers due to its excellent waterproof properties. PVC can withstand a range of temperatures, typically from -10°C to 60°C, making it suitable for various climates. Its resistance to corrosion and chemicals is another advantage, ensuring longevity in wet environments.

Pros: PVC is relatively inexpensive and easy to manufacture, allowing for cost-effective production in bulk. It is also lightweight, which enhances user comfort.

Cons: However, PVC lacks breathability, which can lead to discomfort during extended wear. Additionally, it can become brittle over time, especially when exposed to UV light.

Impact on Application: PVC is ideal for environments where water exposure is frequent, such as construction sites and outdoor events. However, it may not be suitable for high-temperature applications due to its limited thermal resistance.

Considerations for International Buyers: Compliance with international standards, such as ASTM and DIN, is crucial. Buyers from regions like Europe may prefer PVC that meets specific environmental regulations regarding phthalates and other additives.

What Advantages Does EVA Offer for Raincoat Shoe Covers?

Ethylene Vinyl Acetate (EVA) is another popular choice for raincoat shoe covers, known for its flexibility and shock-absorption properties. EVA maintains performance across a wide temperature range, typically from -30°C to 70°C.

Pros: The material is lightweight and provides a comfortable fit, making it suitable for prolonged use. EVA is also resistant to UV radiation, which helps maintain its integrity over time.

Cons: On the downside, EVA can be more expensive than PVC, which may affect pricing strategies for bulk orders. Its durability is also lower when compared to more robust materials like rubber.

Impact on Application: EVA is suitable for applications requiring comfort and flexibility, such as outdoor recreational activities. However, its limited durability may not make it the best choice for heavy-duty industrial applications.

Considerations for International Buyers: Buyers should consider EVA’s compliance with local regulations, especially in regions like Germany, where strict environmental standards are enforced.

How Does Rubber Compare as a Material for Raincoat Shoe Covers?

Rubber, particularly natural rubber or synthetic variants, offers excellent waterproofing and durability. It can withstand extreme temperatures, ranging from -40°C to 100°C, making it suitable for diverse climates.

Pros: Rubber is highly durable and resistant to wear and tear, providing a long lifespan for raincoat shoe covers. Its elasticity ensures a snug fit, enhancing comfort during use.

Cons: The primary drawback is the higher cost associated with rubber compared to PVC and EVA. Additionally, rubber can be heavier, which may deter some users.

Impact on Application: Rubber is ideal for industrial applications where heavy-duty protection is required, such as in manufacturing or construction. Its superior grip makes it suitable for wet and slippery surfaces.

Considerations for International Buyers: Buyers should ensure that the rubber used complies with international standards, particularly in regions with stringent safety regulations like Europe and North America.

What Role Does Polypropylene Play in Raincoat Shoe Covers?

Polypropylene (PP) is a thermoplastic polymer known for its resistance to moisture and chemicals. It typically performs well within a temperature range of -20°C to 80°C.

Pros: PP is lightweight and offers excellent resistance to various chemicals, making it suitable for use in environments where exposure to liquids is common. It is also recyclable, appealing to environmentally conscious buyers.

Cons: However, polypropylene lacks the durability of rubber and can degrade over time when exposed to UV light. Its lower flexibility may also limit comfort during extended wear.

Impact on Application: PP is suitable for lightweight applications, such as food service or cleaning, where protection from liquids is essential. However, its limited durability may not make it ideal for heavy-duty uses.

Considerations for International Buyers: Compliance with food safety standards is crucial for buyers in the food service industry, particularly in regions like South America, where regulations may vary.

Summary Table of Material Selection for Raincoat Shoe Covers

| Material | Typical Use Case for Raincoat Shoe Cover | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Construction sites, outdoor events | Cost-effective, lightweight | Lacks breathability, can become brittle | Low |

| EVA | Outdoor recreational activities | Flexible, comfortable | Higher cost, lower durability | Medium |

| Rubber | Heavy-duty industrial applications | Highly durable, excellent grip | Higher cost, heavier | High |

| Polypropylene | Food service, cleaning | Chemical resistance, recyclable | Lower durability, UV degradation | Medium |

This strategic material selection guide provides essential insights for international B2B buyers considering raincoat shoe covers, enabling informed decisions based on specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for raincoat shoe cover

What Are the Key Stages in the Manufacturing Process of Raincoat Shoe Covers?

The manufacturing process for raincoat shoe covers involves several critical stages that ensure the end product meets quality and performance standards. Understanding these stages is vital for B2B buyers looking to source reliable products.

Material Preparation: What Materials Are Used?

The first stage in manufacturing raincoat shoe covers is material selection and preparation. Typically, high-quality waterproof materials such as PVC (polyvinyl chloride), EVA (ethylene-vinyl acetate), and PE (polyethylene) are used for their durability and water resistance. The chosen material undergoes thorough inspection to ensure it meets the necessary specifications, including thickness, tensile strength, and elasticity. Additionally, suppliers often source materials from certified vendors to ensure compliance with international safety standards.

How Are Raincoat Shoe Covers Formed?

After material preparation, the next step is forming the shoe covers. This involves cutting the material into predetermined patterns, which can be done using automated cutting machines for precision. Techniques such as heat sealing, ultrasonic welding, or stitching are employed to bond the edges of the covers, ensuring they are watertight. The choice of technique can affect the flexibility and durability of the final product, making it essential for manufacturers to choose the right method based on their product specifications.

What Happens During the Assembly Process?

The assembly process involves combining various components of the shoe covers. This may include attaching straps, Velcro fasteners, or elastic bands to ensure a secure fit. Quality control is critical at this stage to ensure that all components are correctly assembled and that the shoe covers can withstand typical usage conditions. Manufacturers often conduct a preliminary quality check to catch any defects before moving to the finishing stage.

How Is the Finishing Stage Conducted?

The finishing stage includes a series of processes that enhance the aesthetic and functional qualities of the shoe covers. This may involve applying additional coatings for UV resistance or anti-slip properties. Once finished, each batch of shoe covers is cleaned and packaged according to industry standards, ensuring they are ready for shipment. Proper packaging is also crucial, as it protects the product during transportation and storage.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance (QA) is a fundamental aspect of the manufacturing process that ensures the final product meets the required standards. B2B buyers must be aware of the relevant international standards and industry-specific certifications that govern the quality of raincoat shoe covers.

Which International Standards Are Relevant for Quality Control?

One of the key international standards for quality management systems is ISO 9001. This standard focuses on ensuring consistent quality across all manufacturing processes and provides a framework for continuous improvement. Additionally, for products sold within the European Union, CE marking may be required, indicating conformity with health, safety, and environmental protection standards.

What Are the Common QC Checkpoints in Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to catch defects early and maintain product integrity. The main checkpoints include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks are conducted during manufacturing to ensure processes are followed correctly.

- Final Quality Control (FQC): The finished products undergo thorough testing, including waterproof testing and durability assessments, before packaging.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is essential for B2B buyers to ensure they receive reliable products. Here are actionable steps buyers can take:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request quality assurance documentation, including audit reports, certifications, and compliance statements. A reputable supplier will have transparent processes and be willing to share their quality control documentation. Additionally, conducting on-site audits can provide insight into a supplier’s manufacturing processes and quality management systems.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control processes. These inspections can include factory audits, product sampling, and performance testing, giving buyers confidence in the supplier’s ability to deliver quality products consistently.

What Are the Specific Quality Control Considerations for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate various challenges related to quality control.

How Do Regional Regulations Impact Quality Assurance?

Different regions may have specific regulations regarding product safety and quality. For instance, buyers in Europe must ensure compliance with EU regulations, while those in the Middle East may need to consider local standards. Understanding these nuances is crucial for avoiding compliance issues and ensuring smooth market entry.

What Are the Common Testing Methods for Raincoat Shoe Covers?

To ensure the performance of raincoat shoe covers, several testing methods are commonly employed:

- Waterproof Testing: This involves submerging the covers to check for leaks.

- Tensile Strength Testing: This assesses the durability of the material under stress.

- Flexibility Testing: This evaluates how well the material can bend without cracking.

Conclusion: Ensuring Quality in Raincoat Shoe Covers

For B2B buyers, understanding the manufacturing processes and quality assurance measures for raincoat shoe covers is essential. By focusing on material selection, manufacturing techniques, and rigorous quality control standards, buyers can make informed decisions and ensure they source high-quality products. Engaging with suppliers who adhere to international standards and are willing to provide transparency in their processes will further enhance the reliability of the products purchased.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘raincoat shoe cover’

To assist international B2B buyers in sourcing high-quality raincoat shoe covers, this practical guide outlines essential steps to ensure that your procurement process is efficient and effective. By following this checklist, you can make informed decisions that align with your business needs and regional requirements.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s critical to outline the technical specifications for the raincoat shoe covers you need. Consider factors such as material type, waterproof capabilities, size range, and any specific features like slip resistance or ease of wear. This clarity will guide your search and help ensure that the products meet your operational requirements.

Step 2: Research Supplier Options

Conduct comprehensive research to identify potential suppliers that specialize in raincoat shoe covers. Utilize online platforms, trade directories, and industry publications to compile a list of candidates. Pay attention to suppliers with a strong reputation in your target markets, particularly in regions like Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Verify their production capabilities and ensure they can meet your volume requirements. Look for suppliers that have a proven track record of quality and reliability.

Step 4: Request Samples for Quality Assessment

Once you have shortlisted potential suppliers, request samples of the raincoat shoe covers. This step allows you to assess the quality, fit, and functionality of the products firsthand. Evaluate how well the samples perform under conditions that mimic your intended use, such as exposure to water and dirt.

Step 5: Negotiate Pricing and Terms

After selecting your preferred supplier based on quality assessments, enter negotiations regarding pricing and terms. Be clear about your budget and explore bulk purchase discounts. Also, discuss payment terms, delivery schedules, and any warranties or return policies that may apply to the products.

Step 6: Verify Compliance and Certifications

Ensure that the supplier’s products comply with relevant industry standards and regulations. This is especially important if you are sourcing from regions with specific compliance requirements. Request copies of certifications and safety data sheets to confirm that the raincoat shoe covers meet necessary legal and quality benchmarks.

Step 7: Establish a Communication Plan

Once you’ve finalized your supplier, set up a clear communication plan to facilitate smooth transactions. Define points of contact, preferred communication channels, and regular check-in intervals. This ensures that any issues can be addressed promptly, helping to maintain a strong supplier relationship throughout the procurement process.

By following this checklist, B2B buyers can confidently navigate the sourcing of raincoat shoe covers, ensuring they procure products that meet their needs while fostering successful supplier partnerships.

Comprehensive Cost and Pricing Analysis for raincoat shoe cover Sourcing

Analyzing the cost structure and pricing strategies for sourcing raincoat shoe covers is essential for international B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. This section delves into the key components influencing costs, price determinants, and valuable buyer tips to enhance procurement efficiency.

What Are the Key Cost Components in Raincoat Shoe Cover Manufacturing?

Materials: The choice of materials significantly impacts the overall cost of raincoat shoe covers. Commonly used materials include waterproof polyethylene, rubber, and various synthetic fibers. Higher quality materials typically lead to increased durability and performance, thus elevating the price.

Labor: Labor costs can vary widely depending on the production location. Regions with lower labor costs may provide a competitive advantage, but it is crucial to assess the quality of workmanship, as this can affect the final product’s integrity.

Manufacturing Overhead: This includes costs associated with the production facility, equipment, utilities, and administrative expenses. Efficient production processes can reduce overhead costs, allowing suppliers to offer more competitive pricing.

Tooling: Initial tooling costs for molds and machinery setup can be significant, especially for custom designs. Buyers should consider these costs in the total cost analysis, particularly when placing larger orders that justify the upfront investment.

Quality Control (QC): Implementing stringent QC processes is vital to ensure product reliability. While this adds to the cost, it can prevent returns and enhance customer satisfaction, ultimately contributing to long-term savings.

Logistics: Shipping and handling costs vary based on the supplier’s location, the shipping method chosen, and the Incoterms agreed upon. Buyers should account for both domestic and international logistics when calculating total costs.

Margin: Suppliers typically mark up their costs to establish a profit margin. Understanding the average margins in the industry can provide insight into pricing strategies and help buyers negotiate better deals.

What Factors Influence Pricing for Raincoat Shoe Covers?

Volume and Minimum Order Quantity (MOQ): Pricing often decreases with larger order quantities. Buyers should negotiate MOQs that align with their demand forecasts to optimize costs.

Specifications and Customization: Customized designs or specific material requirements can lead to higher prices. It is advisable to assess whether the added cost aligns with the expected benefits of customization.

Quality and Certifications: Certifications (e.g., ISO, CE) can enhance the perceived value of the product. Buyers seeking certified products may pay a premium, but these certifications often ensure compliance with safety and quality standards.

Supplier Factors: The reputation and reliability of the supplier play a critical role in pricing. Established suppliers with a track record of quality may command higher prices, but they often provide better service and product consistency.

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for pricing. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact the total landed cost.

What Tips Can Enhance Cost-Efficiency for International B2B Buyers?

Negotiate Effectively: Leverage your purchasing power by negotiating terms and pricing. Establish long-term relationships with suppliers to create more favorable conditions.

Evaluate Total Cost of Ownership (TCO): Beyond the purchase price, consider the TCO, which includes shipping, customs duties, and potential warranty claims. This holistic view can uncover hidden costs that affect profitability.

Understand Pricing Nuances: Different markets may exhibit unique pricing structures due to local demand, competition, and economic conditions. Tailoring procurement strategies to align with regional dynamics can yield cost savings.

Consider Local Suppliers: Sourcing from local manufacturers can reduce shipping costs and lead times, enhancing responsiveness to market demands.

Stay Informed: Keep abreast of market trends and shifts in material costs, labor rates, and geopolitical factors that can influence pricing. This knowledge can empower buyers to make informed decisions and capitalize on favorable conditions.

In conclusion, navigating the complexities of sourcing raincoat shoe covers requires a comprehensive understanding of cost components and pricing dynamics. By leveraging the insights provided here, B2B buyers can enhance their procurement strategies and achieve greater cost efficiency in their operations.

Alternatives Analysis: Comparing raincoat shoe cover With Other Solutions

When evaluating raincoat shoe covers, it is essential to consider alternative solutions that serve the same purpose of protecting footwear from water and dirt. This comparison will help B2B buyers identify the best option tailored to their needs, especially in regions prone to wet conditions, such as parts of Africa, South America, the Middle East, and Europe.

| Comparison Aspect | Raincoat Shoe Cover | Waterproof Boot Covers | Disposable Shoe Covers |

|---|---|---|---|

| Performance | Excellent waterproofing; protects shoes and lower legs from rain and dirt. | High-level waterproofing; often covers more area, including the calf. | Basic waterproofing; protects shoes but can be less durable. |

| Cost | Moderate investment, typically priced between €25-€50 per pair. | Higher cost, generally ranges from €30-€100 depending on materials and durability. | Low-cost solution, ranging from €0.10 to €1.00 per pair. |

| Ease of Implementation | Simple to put on and take off; generally fits most shoe sizes. | May require sizing for specific footwear; some designs can be cumbersome. | Extremely easy to use; simply slip on over shoes. |

| Maintenance | Reusable; requires occasional cleaning to maintain performance. | Reusable; may require more thorough cleaning due to larger surface area. | Single-use; no maintenance, but generates waste. |

| Best Use Case | Ideal for urban commuting, cycling, and casual outdoor activities. | Best for construction, agriculture, and high-exposure environments. | Suitable for temporary use in medical, food service, or events. |

What Are the Advantages and Disadvantages of Waterproof Boot Covers?

Waterproof boot covers offer a significant advantage in terms of coverage, as they often extend higher on the leg, providing more comprehensive protection against rain and mud. They are particularly useful in industries where prolonged exposure to wet conditions is common, such as construction or agriculture. However, their higher cost and the potential for cumbersome wear can be drawbacks for businesses seeking quick, efficient solutions.

How Do Disposable Shoe Covers Compare?

Disposable shoe covers are a cost-effective alternative, especially for industries that require frequent changes, such as healthcare or food service. Their low cost makes them accessible for bulk purchasing, but their limited durability and environmental impact may deter businesses focused on sustainability. Additionally, they provide basic protection, which may not be sufficient for more rugged outdoor conditions.

Making the Right Choice for Your Business Needs

Choosing the right footwear protection solution depends on your specific operational needs and budget. For businesses in urban settings or those needing lightweight, portable solutions, raincoat shoe covers may offer the perfect balance of performance and ease of use. Conversely, if your operations involve high exposure to wet conditions or require more robust protection, waterproof boot covers may be the better option. On the other hand, if cost is a primary concern and the use is temporary, disposable shoe covers may suffice, despite their environmental considerations.

Ultimately, understanding the unique requirements of your business will guide you in selecting the most suitable protective footwear solution, ensuring both employee comfort and operational efficiency.

Essential Technical Properties and Trade Terminology for raincoat shoe cover

What Are the Key Technical Properties of Raincoat Shoe Covers?

When sourcing raincoat shoe covers, understanding the technical specifications is crucial for ensuring quality and performance. Here are some essential properties to consider:

1. Material Grade

The material used in raincoat shoe covers significantly impacts their waterproofing capabilities and durability. Common materials include PVC, polyethylene, and rubber. Each material has varying degrees of water resistance, flexibility, and durability. For instance, PVC is robust and offers excellent waterproof properties but can be less breathable, while silicone may provide enhanced flexibility and comfort.

2. Water Resistance Rating (WRR)

The water resistance rating indicates how well a material can withstand water exposure. This rating is essential for B2B buyers in sectors such as construction, outdoor activities, or food service, where exposure to moisture is common. A higher WRR ensures that the shoe covers remain effective in heavy rain, protecting both shoes and the wearer’s feet.

3. Weight and Portability

The weight of the shoe covers affects their portability and ease of use. Lightweight options are preferable for industries requiring mobility, such as delivery services or outdoor event management. Buyers should look for products that balance weight with durability to ensure they can be easily carried without compromising on performance.

4. Size Range and Fit

A versatile size range is crucial for accommodating different shoe types and sizes. Many products offer a “one size fits all” approach, but it’s essential to verify that they can adequately fit various shoe designs, from sneakers to work boots. Proper fit ensures maximum protection and comfort for the wearer.

5. Slip Resistance

For safety-critical environments, the slip resistance of the shoe covers is vital. Materials with textured soles or specific coatings can prevent slips and falls, particularly in wet conditions. This feature is particularly significant for industries like hospitality, where workers are often on their feet in potentially hazardous conditions.

6. Reusable vs. Disposable

Buyers should consider whether they need reusable or disposable shoe covers based on their operational needs. Reusable covers, while initially more expensive, can provide long-term savings and sustainability benefits. Conversely, disposable covers are ideal for short-term use or environments where hygiene is paramount.

What Are Common Trade Terms in the Raincoat Shoe Cover Industry?

Understanding trade terminology is essential for effective communication and negotiation in B2B transactions. Here are several key terms relevant to raincoat shoe covers:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on specifications provided by another company. In the raincoat shoe cover industry, an OEM might produce custom designs for brands looking to enter the market without investing in manufacturing facilities.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding the MOQ is crucial for budgeting and inventory management. Suppliers may set MOQs based on production costs, and negotiating this can impact the overall purchase price.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products. In the context of raincoat shoe covers, submitting an RFQ allows buyers to compare prices and terms from multiple suppliers, aiding in informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping, including who pays for shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers understand their obligations and negotiate better shipping agreements.

5. Lead Time

Lead time refers to the duration from placing an order to receiving the product. In the raincoat shoe cover industry, lead times can vary based on manufacturing processes and shipping methods. Understanding lead times helps businesses plan their inventory and operational needs effectively.

6. Certification Standards

Certification standards, such as ISO or ASTM, indicate that products meet specific safety and quality benchmarks. For B2B buyers, sourcing certified raincoat shoe covers can mitigate risks and enhance product credibility in the market.

By being aware of these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the raincoat shoe cover Sector

What Are the Key Market Dynamics and Trends Shaping the Raincoat Shoe Cover Sector?

The global market for raincoat shoe covers is experiencing significant growth driven by several factors. Increasing urbanization and adverse weather conditions, particularly in regions like Africa, South America, and the Middle East, have led to a rising demand for protective footwear solutions. These covers are not only functional but also increasingly seen as essential for maintaining professional appearances in sectors such as construction, hospitality, and outdoor events.

Emerging technologies are reshaping sourcing strategies within this market. B2B buyers are now leveraging digital platforms for procurement, utilizing e-commerce solutions that offer extensive product catalogs and streamlined ordering processes. Suppliers that can provide real-time inventory updates and flexible shipping options are gaining a competitive edge. Additionally, there’s a growing trend towards customization, where businesses seek tailored solutions to meet specific industry needs, such as non-slip soles for construction workers or lightweight designs for cyclists.

Furthermore, European markets, particularly Germany, are leading the charge in adopting innovative materials, such as recycled plastics and eco-friendly coatings, which cater to the increasing demand for sustainable products. The rise of e-commerce and direct-to-consumer models also allows international buyers to source directly from manufacturers, thereby reducing costs and enhancing supply chain efficiency.

How Is Sustainability Influencing the Sourcing of Raincoat Shoe Covers in B2B?

Sustainability has become a pivotal aspect of sourcing in the raincoat shoe cover sector. With growing environmental concerns, B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes using environmentally friendly materials and processes, which not only reduce carbon footprints but also resonate with consumers who are more conscious of their purchasing decisions.

Ethical sourcing is equally critical. Buyers are now scrutinizing supply chains to ensure fair labor practices and responsible sourcing of materials. Certifications such as Global Organic Textile Standard (GOTS) or the Forest Stewardship Council (FSC) can significantly enhance a supplier’s credibility. Businesses that can showcase their commitment to sustainability and ethical practices are more likely to attract international buyers who align with these values.

Moreover, the demand for green certifications is rising. Buyers are looking for products made from recycled or biodegradable materials, which can also serve as a unique selling proposition. Suppliers that invest in these sustainable innovations not only contribute positively to the environment but also enhance their market positioning, making them more appealing to B2B buyers across various regions.

What Has Been the Evolution of Raincoat Shoe Covers in the B2B Market?

The evolution of raincoat shoe covers has been influenced by changing consumer needs and technological advancements. Initially designed primarily for utility, these products have transformed into fashionable and functional items that cater to a diverse range of industries. Over the decades, advancements in materials science have led to the development of lighter, more durable, and waterproof materials, which have significantly improved the performance of raincoat shoe covers.

Historically, rain covers were predominantly used in specific sectors like construction and agriculture. However, as urban lifestyles evolved, the demand expanded to include outdoor enthusiasts and commuters, prompting manufacturers to innovate designs that are not only protective but also stylish. Today, the market includes various types of shoe covers, from disposable versions used in cleanrooms and food services to high-end, reusable options designed for everyday wear.

This evolution reflects a broader trend towards multifunctionality and adaptability in product design, driven by consumer preferences and market demands. As B2B buyers seek versatile solutions that cater to a wide range of applications, the raincoat shoe cover sector is poised for continued growth and innovation in the years to come.

Frequently Asked Questions (FAQs) for B2B Buyers of raincoat shoe cover

-

1. How do I choose the right raincoat shoe cover for my business needs?

When selecting raincoat shoe covers, consider factors such as the specific industry application (e.g., construction, food service, or outdoor activities), material durability, and waterproof ratings. Assess whether you need disposable or reusable options based on your operational needs and budget. Additionally, evaluate the sizing options available, ensuring they fit a wide range of shoe sizes to accommodate your workforce. Supplier reviews and product samples can also help you determine the best fit for your requirements. -

2. What are the key features to look for in waterproof shoe covers?

Key features to consider include the waterproof material’s quality, breathability, and ease of wear. Look for slip-resistant soles to ensure safety in wet conditions and adjustable closures for a secure fit. The weight and packability of the covers are important for ease of storage and transportation. Lastly, check for any certifications or ratings that guarantee the product meets industry standards, which can enhance your credibility with clients. -

3. What is the minimum order quantity (MOQ) for raincoat shoe covers?

MOQs for raincoat shoe covers vary significantly by supplier and product type. Generally, you can expect MOQs to range from 100 to 1,000 pairs, depending on the manufacturer and whether the covers are customized. It’s advisable to discuss your needs directly with suppliers to negotiate favorable terms. Smaller businesses may benefit from finding suppliers who offer flexible ordering options or bulk purchasing discounts. -

4. How can I vet suppliers for raincoat shoe covers internationally?

Vetting suppliers is crucial to ensure product quality and reliability. Start by checking their business credentials, including certifications and years of operation. Request references from previous clients and analyze reviews on independent platforms. Conducting a factory visit or requesting product samples can help assess quality standards. Additionally, consider suppliers who participate in trade shows or have a strong online presence, indicating they are reputable in the industry. -

5. What payment terms should I expect when sourcing raincoat shoe covers?

Payment terms can vary widely depending on the supplier and your negotiation power. Common terms include a 30% deposit upfront with the balance due upon shipment, or net 30/60 days after receiving the goods. Be sure to clarify payment methods accepted, such as wire transfers, letters of credit, or PayPal. Establishing clear terms in a written contract can protect both parties and ensure a smooth transaction process. -

6. What are the shipping and logistics considerations for importing raincoat shoe covers?

When importing, consider shipping methods (air vs. sea), costs, and delivery timelines. Air freight is faster but more expensive, while sea freight is cost-effective for large orders but may take longer. Ensure that your supplier provides all necessary documentation for customs clearance, including invoices and packing lists. Working with a reliable freight forwarder can help manage logistics, ensuring compliance with international regulations and reducing delays. -

7. Can I customize raincoat shoe covers with my branding?

Many suppliers offer customization options for raincoat shoe covers, allowing you to add your logo or specific color schemes. The extent of customization will depend on the manufacturer and the order quantity. Typically, higher MOQs are required for custom designs to offset setup costs. Discuss your branding needs with potential suppliers to explore available options and associated costs. -

8. How do I ensure quality assurance for raincoat shoe covers?

To ensure quality, work with suppliers who have established quality assurance processes. Request information on their testing protocols and certifications. Consider implementing a quality control inspection before shipment, especially for large orders. Additionally, maintain open communication with suppliers to address any concerns promptly and establish a feedback loop for continuous improvement in product quality.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 2 Raincoat Shoe Cover Manufacturers & Suppliers List

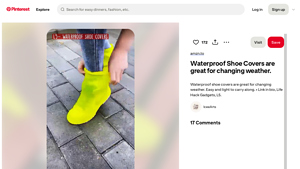

1. SooGree – Waterproof Rain Boot Covers

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: SooGree Rain Boot Covers, Waterproof Rain Shoe Covers, Silicone Shoe Protector, Overshoes, Sand Control, Non-Slip, Foldable, Reusable Galoshes for Men and Women, suitable for rainy outdoor conditions.

2. Target – Waterproof Rain Shoe Covers

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Waterproof Rain Shoe Covers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for raincoat shoe cover

In conclusion, the strategic sourcing of raincoat shoe covers presents a significant opportunity for international B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe. The demand for waterproof and protective footwear solutions is on the rise, driven by increasing awareness of workplace safety and environmental factors. Sourcing high-quality raincoat shoe covers can enhance operational efficiency, protect valuable footwear, and ultimately contribute to customer satisfaction across various industries, including construction, food service, and outdoor activities.

As you consider your sourcing strategies, prioritize suppliers that offer durable, cost-effective, and versatile options. Engaging with manufacturers who emphasize innovation in materials and design will not only ensure compliance with industry standards but also enhance your competitive edge.

Looking ahead, the market for raincoat shoe covers is poised for growth as weather variability becomes more pronounced and sustainability becomes a core value for consumers. Now is the time to leverage this trend—connect with reliable suppliers, explore bulk purchasing options, and ensure your inventory meets the evolving needs of your clientele. Take action today to secure your position in this expanding market and set the stage for future success.