Introduction: Navigating the Global Market for PVC Rain Poncho

In today’s unpredictable climate, sourcing high-quality PVC rain ponchos presents a unique challenge for international B2B buyers. As weather patterns become increasingly erratic, businesses across Africa, South America, the Middle East, and Europe—particularly in regions like Nigeria and Germany—are seeking reliable rainwear solutions that offer both durability and comfort. This comprehensive guide delves into the global market for PVC rain ponchos, providing insights into various types, applications, and key factors for successful supplier vetting.

Throughout this guide, you will discover the diverse range of PVC rain ponchos available, from lightweight options ideal for outdoor events to heavyweight designs suited for industrial use. We will also explore essential considerations such as material specifications, safety regulations, and pricing strategies, enabling you to make informed purchasing decisions. Additionally, we highlight best practices for evaluating suppliers to ensure you partner with reputable manufacturers who meet your quality standards and logistical requirements.

By equipping yourself with this knowledge, you empower your business to navigate the complexities of sourcing PVC rain ponchos effectively. Whether you are looking to enhance your product offerings or ensure employee safety during inclement weather, this guide serves as a vital resource for informed decision-making in the global market.

Article Navigation

- Top 1 Pvc Rain Poncho Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for PVC Rain Poncho

- Understanding PVC Rain Poncho Types and Variations

- Key Industrial Applications of PVC Rain Poncho

- 3 Common User Pain Points for ‘PVC Rain Poncho’ & Their Solutions

- Strategic Material Selection Guide for PVC Rain Poncho

- In-depth Look: Manufacturing Processes and Quality Assurance for PVC Rain Poncho

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘PVC Rain Poncho’

- Comprehensive Cost and Pricing Analysis for PVC Rain Poncho Sourcing

- Alternatives Analysis: Comparing PVC Rain Poncho With Other Solutions

- Essential Technical Properties and Trade Terminology for PVC Rain Poncho

- Navigating Market Dynamics and Sourcing Trends in the PVC Rain Poncho Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of PVC Rain Poncho

- Important Disclaimer & Terms of Use

- Strategic Sourcing Conclusion and Outlook for PVC Rain Poncho

Understanding PVC Rain Poncho Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lightweight PVC Rain Poncho | 0.10mm thickness, large size (50″ x 80″), attached hood | Short-term events, outdoor activities, emergency kits | Pros: Cost-effective, portable. Cons: Less durable, limited protection in heavy rain. |

| Heavyweight PVC Rain Poncho | Thicker material (0.35mm), more robust construction | Industrial applications, heavy-duty outdoor use | Pros: Superior durability, better weather resistance. Cons: Bulkier, higher cost. |

| Reversible PVC Poncho | Two-sided design, secure snap closures | Emergency services, outdoor recreation, camping | Pros: Versatile visibility, added functionality. Cons: Potentially higher price, heavier weight. |

| PVC-Coated Nylon Poncho | Combination of PVC and nylon, lightweight | Retail, casual outdoor use, promotional events | Pros: Lightweight, stylish options available. Cons: May not be as waterproof as pure PVC. |

| Emergency Poncho | Ultra-lightweight, compact, single-use | Disaster relief, personal safety kits | Pros: Extremely portable, low-cost. Cons: Limited durability, single-use only. |

What Are the Key Characteristics of Lightweight PVC Rain Ponchos?

Lightweight PVC rain ponchos are designed for quick and easy use, making them ideal for short-term applications such as sporting events or outdoor festivals. Typically made from 0.10mm PVC, these ponchos are large enough to fit most body types (around 50″ x 80″) and often come with an attached hood. B2B buyers focusing on budget-friendly options for temporary solutions will find these ponchos suitable, although they may not offer the durability required for prolonged exposure to heavy rain.

How Do Heavyweight PVC Rain Ponchos Differ in Functionality?

Heavyweight PVC rain ponchos are crafted from thicker materials, often around 0.35mm, which provides enhanced durability and weather resistance. These ponchos are well-suited for industrial applications, where users may be exposed to harsher weather conditions for extended periods. B2B buyers in sectors such as construction or agriculture will appreciate the robust construction, although they should be aware that these ponchos can be bulkier and more expensive than their lightweight counterparts.

What Advantages Do Reversible PVC Ponchos Offer to Businesses?

Reversible PVC ponchos feature a dual-sided design, often with one side in a bright color for visibility in emergencies. These ponchos are ideal for outdoor recreation and emergency services, providing added functionality for B2B buyers needing reliable rain gear. The secure snap closures ensure a snug fit during inclement weather. However, the additional features may come at a higher price point, making it essential for buyers to evaluate their specific needs against cost.

In What Scenarios Are PVC-Coated Nylon Ponchos Most Effective?

PVC-coated nylon ponchos blend the lightweight nature of nylon with the waterproof properties of PVC, making them an attractive option for retail and casual outdoor use. These ponchos often come in various colors and styles, appealing to businesses looking to enhance brand visibility at promotional events. While they are generally lighter and more stylish, buyers should consider that they may not provide the same level of waterproofing as pure PVC options.

Why Should Businesses Consider Emergency Ponchos?

Emergency ponchos are ultra-lightweight and compact, designed primarily for single-use scenarios. They are ideal for disaster relief efforts and personal safety kits, making them a critical component for organizations focused on preparedness. The low cost and portability of these ponchos are significant advantages; however, buyers should be mindful of their limited durability and suitability for only short-term use.

Key Industrial Applications of PVC Rain Poncho

| Industry/Sector | Specific Application of PVC Rain Poncho | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Outdoor Events | Protection for staff and attendees during events | Ensures comfort and safety, enhancing event experience | Bulk purchasing, customization options, and rapid delivery |

| Agriculture | Protection for workers during unpredictable weather | Minimizes work disruptions and enhances worker safety | Durability, compliance with local regulations, and size variations |

| Emergency Services | Emergency preparedness kits for first responders | Provides essential protection in adverse weather | Lightweight design, ease of storage, and visibility features |

| Construction | Protection for workers on-site during rain | Reduces downtime, enhances safety compliance | Heavy-duty materials, availability of different sizes, and color options |

| Travel and Tourism | Essential gear for tour guides and travelers | Enhances customer satisfaction and safety | Waterproof features, portability, and branding options |

How are PVC Rain Ponchos Utilized in Outdoor Events?

In the outdoor events sector, PVC rain ponchos serve as a critical solution for protecting both staff and attendees from unexpected rain. These ponchos are lightweight and easy to distribute, ensuring that everyone remains dry and comfortable, which significantly enhances the overall event experience. For B2B buyers, key considerations include bulk purchasing options to ensure adequate supply, customization features for branding, and reliable delivery timelines to meet event schedules. This is particularly relevant for international buyers in regions prone to sudden weather changes, such as parts of Africa and South America.

What Role Do PVC Rain Ponchos Play in Agriculture?

In agriculture, PVC rain ponchos are essential for protecting workers from the elements during unpredictable weather conditions. They help minimize work disruptions caused by rain, allowing agricultural operations to continue smoothly. For businesses in this sector, sourcing considerations include the durability of the ponchos, compliance with local safety regulations, and the availability of various sizes to accommodate all workers. This is especially vital for agricultural firms in Europe and the Middle East, where seasonal weather fluctuations can impact productivity.

How Do Emergency Services Use PVC Rain Ponchos?

Emergency services utilize PVC rain ponchos as a part of their preparedness kits for first responders. These ponchos offer essential protection during adverse weather conditions, ensuring that responders can operate effectively while remaining dry. The lightweight design makes them easy to store and transport, which is crucial for emergency situations. B2B buyers in this sector should consider sourcing ponchos that feature high visibility for safety and quick identification during emergencies, particularly in urban areas across Europe and Africa.

Why are PVC Rain Ponchos Important in Construction?

In the construction industry, PVC rain ponchos are vital for protecting workers on-site during rainstorms. Keeping employees dry not only enhances safety compliance but also reduces downtime due to weather interruptions. When sourcing these ponchos, businesses should prioritize heavy-duty materials that can withstand harsh conditions, as well as the availability of different sizes and colors to meet site-specific needs. This is particularly relevant for construction firms operating in regions with variable climates, such as South America and the Middle East.

How Do Travel and Tourism Benefit from PVC Rain Ponchos?

In the travel and tourism sector, PVC rain ponchos are indispensable for tour guides and travelers. They provide a practical solution for unexpected rain, enhancing customer satisfaction and safety during excursions. B2B buyers should consider waterproof features, portability for ease of carrying, and options for branding to promote their services. This is especially relevant for businesses targeting international tourists in Europe and Africa, where weather conditions can vary widely throughout the year.

3 Common User Pain Points for ‘PVC Rain Poncho’ & Their Solutions

Scenario 1: Sourcing Durable PVC Rain Ponchos for Harsh Weather Conditions

The Problem:

B2B buyers in regions prone to heavy rainfall, such as parts of Africa and South America, often face the challenge of sourcing rain ponchos that can withstand harsh weather conditions. Many available options are either too flimsy or lack the necessary durability to offer adequate protection during intense downpours. This leads to dissatisfaction among end-users, who expect reliable products that won’t tear or degrade after a single use. The risk of investing in low-quality ponchos can also result in increased returns and customer complaints, ultimately harming the buyer’s reputation and bottom line.

The Solution:

To ensure sourcing of durable PVC rain ponchos, buyers should prioritize products made from heavy-gauge PVC material, typically around 0.20mm thickness, which can withstand extreme weather conditions. Engage with suppliers who provide detailed specifications and performance tests for their products, ensuring they meet industry standards for durability. It’s also beneficial to request samples before placing bulk orders, allowing for real-world testing to confirm that the ponchos can endure the specific environmental conditions they will face. Establishing relationships with reputable manufacturers who specialize in outdoor gear can further ensure product reliability and quality assurance.

Scenario 2: Ensuring Proper Fit and Comfort for Diverse Users

The Problem:

B2B buyers often cater to a wide range of end-users, from construction workers in Europe to outdoor enthusiasts in the Middle East. One common pain point is the challenge of ensuring that rain ponchos fit comfortably across diverse body types and sizes. A one-size-fits-all approach may leave some users underprotected or uncomfortable, leading to reduced satisfaction and potential safety risks in environments where mobility is crucial.

The Solution:

Buyers should consider sourcing ponchos that offer various size options or adjustable features, such as snap closures and drawstrings, to enhance fit and comfort. When evaluating suppliers, inquire about their size range and any customization options available. Additionally, providing sizing charts and fitting guides can help end-users select the right product for their needs, thereby improving user experience and satisfaction. Encouraging feedback from users on fit can also help refine future orders and ensure that the ponchos meet the expectations of all user demographics.

Scenario 3: Addressing Environmental and Safety Concerns

The Problem:

With increasing awareness around environmental issues and product safety, B2B buyers face pressure to ensure that the PVC rain ponchos they purchase comply with safety regulations and are produced sustainably. Concerns over harmful chemicals, such as phthalates, used in manufacturing these ponchos can deter buyers, particularly in regions like Europe where regulatory scrutiny is high. Additionally, the impact of non-biodegradable materials on the environment is an ongoing concern for companies looking to improve their sustainability practices.

The Solution:

To address these environmental and safety concerns, buyers should conduct thorough research on the materials used in the ponchos they intend to purchase. Partnering with manufacturers who comply with environmental regulations and offer certifications can help ensure product safety. Look for PVC rain ponchos that are labeled as free from harmful chemicals and explore options made from recycled materials. By sourcing from environmentally responsible suppliers, buyers can not only meet compliance standards but also position themselves as leaders in sustainability, appealing to eco-conscious consumers and partners. Providing transparency about sourcing practices can enhance brand reputation and foster trust among customers.

Strategic Material Selection Guide for PVC Rain Poncho

What Are the Key Properties of Common Materials Used in PVC Rain Ponchos?

When selecting materials for PVC rain ponchos, several options are prevalent in the market, each offering unique properties and benefits. Understanding these materials is crucial for international B2B buyers who need to ensure product performance, compliance, and suitability for their specific markets.

How Does Lightweight PVC Perform in Rain Poncho Applications?

Lightweight PVC, typically around 0.10mm in thickness, is a common choice for rain ponchos. This material is characterized by its flexibility and lightweight nature, making it ideal for short-term use in activities such as hiking or sporting events. Its welded seam construction enhances waterproofing, while the attached hood provides additional protection.

Pros: Lightweight PVC is cost-effective and easy to manufacture, allowing for quick production cycles. Its large size (often around 50″ x 80″) ensures a one-size-fits-most approach, appealing to a broad customer base.

Cons: However, its thinner profile may compromise durability against harsh weather conditions. Additionally, compliance with safety regulations, such as those in California regarding cancer and reproductive harm, is a critical consideration for buyers in regions with strict regulations.

What Are the Benefits of Heavyweight PVC in Rain Ponchos?

Heavyweight PVC, generally ranging from 0.35mm to 0.50mm, offers enhanced durability compared to its lightweight counterpart. This material is suitable for more demanding applications, such as industrial or outdoor work environments where prolonged exposure to rain is expected.

Pros: The increased thickness provides better resistance to tearing and punctures, making it a reliable choice for rugged use. Furthermore, heavyweight PVC can often be treated for additional features like UV resistance, which can be beneficial in sunny climates.

Cons: The downside includes higher production costs and potentially longer lead times due to its more complex manufacturing process. Buyers must also consider the weight factor, as heavier ponchos may not appeal to consumers seeking convenience.

How Does PVC-Coated Nylon Compare for Rain Poncho Production?

PVC-coated nylon combines the lightweight properties of nylon with the waterproofing capabilities of PVC. This hybrid material is gaining traction for rain ponchos due to its excellent balance of weight and durability.

Pros: The fabric is both strong and resistant to abrasion, making it suitable for various outdoor activities. Its breathability also enhances comfort, which is particularly important in warmer climates.

Cons: On the flip side, the coating can wear off over time, reducing the poncho’s effectiveness. Additionally, the manufacturing process may be more complex, leading to higher costs, which could deter budget-conscious buyers.

What Should International Buyers Consider When Selecting PVC Materials?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, compliance with local standards is paramount. Buyers must ensure that the materials used in rain ponchos meet relevant regulations, such as ASTM in the U.S. or DIN in Germany. Additionally, preferences for color, visibility, and additional features like reflective strips may vary by region, influencing purchasing decisions.

Summary Table of Material Selection for PVC Rain Ponchos

| Material | Typical Use Case for PVC Rain Poncho | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lightweight PVC | Short-term use in outdoor events | Cost-effective and lightweight | Less durable in harsh conditions | Low |

| Heavyweight PVC | Industrial and prolonged outdoor use | Enhanced durability | Higher production costs | Med |

| PVC-Coated Nylon | Versatile outdoor activities | Strong and abrasion-resistant | Coating may wear off over time | Med |

| Reversible PVC | Emergency kits and outdoor gear | Visibility in emergencies | More complex manufacturing | High |

This analysis provides a comprehensive overview of the materials used in PVC rain ponchos, highlighting their properties and implications for B2B buyers. Understanding these factors can aid in making informed purchasing decisions that align with market demands and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for PVC Rain Poncho

What Are the Key Stages in the Manufacturing Process of PVC Rain Ponchos?

The manufacturing of PVC rain ponchos involves several critical stages to ensure a high-quality final product. Understanding these stages can provide international B2B buyers with insights into the efficiency and quality of potential suppliers.

Material Preparation: Selecting and Preparing PVC

The first step in the manufacturing process is the selection and preparation of PVC material. The thickness of the PVC, typically around 0.10 mm to 0.35 mm for ponchos, is chosen based on the intended use. This material is sourced from reputable suppliers to ensure durability and compliance with international standards. The PVC is then cut into sheets of appropriate size, allowing for the production of multiple ponchos simultaneously. Additionally, any necessary additives for color or UV resistance may be integrated at this stage.

Forming: Shaping the Poncho

After material preparation, the next phase is forming. This involves cutting the PVC sheets into the required patterns. Advanced cutting technologies, such as laser cutting or die-cutting, are often employed to ensure precision. The cut pieces are then shaped using heat sealing or ultrasonic welding techniques. These methods bond the edges of the poncho to create a waterproof seal, an essential feature for rain protection. This stage may also include adding features like hoods and side snaps, which enhance functionality.

Assembly: Bringing It All Together

Once the individual components are formed, they proceed to the assembly stage. This involves joining the cut and shaped pieces into a complete poncho. Workers or automated systems will align the pieces and use heat sealing to bond them securely. Quality checks are often integrated into this phase to ensure that the assembly meets design specifications. The assembly process might also include the application of additional features such as reflective strips for visibility, especially important for outdoor and safety applications.

Finishing: Final Touches and Quality Checks

The finishing stage is crucial for enhancing the product’s appeal and functionality. This includes trimming any excess material, applying logos or branding, and conducting final inspections. At this point, the ponchos may also undergo additional treatments, such as anti-fungal or anti-bacterial coatings, to improve hygiene and longevity. Proper packaging is also essential, especially for international shipping, to prevent damage during transit.

What Quality Assurance Measures Are Essential for PVC Rain Ponchos?

Quality assurance (QA) is a critical aspect of the manufacturing process, particularly for international B2B buyers who require consistent quality and compliance with various standards.

Which International Standards Should PVC Rain Ponchos Meet?

For PVC rain ponchos, adherence to international standards such as ISO 9001 is essential. This standard focuses on quality management systems and ensures that manufacturers have processes in place to consistently provide products that meet customer and regulatory requirements. Additionally, compliance with CE marking requirements indicates that the products meet EU safety, health, and environmental protection standards. Buyers from regions like Africa, South America, the Middle East, and Europe should verify that suppliers meet these standards to ensure product reliability.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards and are free from defects.

- In-Process Quality Control (IPQC): During manufacturing, random samples are taken to check for defects and adherence to specifications. This ongoing assessment helps catch issues early.

- Final Quality Control (FQC): After assembly and finishing, a final inspection is performed to ensure that the finished ponchos meet all quality standards before packaging.

These checkpoints are essential for maintaining high standards throughout the production process.

What Common Testing Methods Are Used for Quality Assurance?

Testing methods for PVC rain ponchos typically include:

- Waterproof Testing: This ensures that the ponchos can withstand rain without leaking. Testing may involve subjecting the ponchos to simulated rain conditions.

- Durability Testing: This assesses the material’s resistance to tearing and puncturing, simulating real-world usage scenarios.

- Chemical Compliance Testing: Ensuring that the materials used do not contain harmful substances is crucial, especially for markets with strict regulations.

Buyers should inquire about these testing methods when evaluating potential suppliers.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control processes is vital to ensure they receive consistent, high-quality products.

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is one of the most effective ways to verify quality control measures. Buyers should consider the following best practices:

- On-Site Audits: Visiting the manufacturing facility allows buyers to observe the production process firsthand, assess equipment, and evaluate employee training.

- Requesting Documentation: Suppliers should provide documentation of their quality control processes, including inspection reports, certifications, and test results.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance practices. This is particularly valuable for international buyers who may not be able to conduct on-site visits.

What Are the QC Nuances for International Buyers?

International B2B buyers must be aware of specific nuances in quality control that may vary by region. For instance, regulations in Europe may differ significantly from those in Africa or South America. Buyers should familiarize themselves with local standards and ensure that their suppliers are compliant. Additionally, language barriers and cultural differences may impact communication regarding quality expectations, making it essential to establish clear agreements and expectations upfront.

Conclusion

The manufacturing and quality assurance processes for PVC rain ponchos are critical to ensuring that the final product meets the needs of international B2B buyers. By understanding the stages of manufacturing, quality control checkpoints, testing methods, and best practices for supplier verification, buyers can make informed decisions when sourcing these essential products. Ensuring compliance with international standards not only enhances product reliability but also fosters trust and long-term partnerships in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘PVC Rain Poncho’

Introduction

Sourcing PVC rain ponchos for your business can be a complex process, especially when considering the diverse needs of your target market. This guide aims to provide you with a practical checklist to streamline your sourcing efforts, ensuring you select high-quality products that meet the demands of your customers across various regions, including Africa, South America, the Middle East, and Europe.

1. Identify Market Demand

Understanding the specific needs of your target market is crucial. Research regional weather patterns, outdoor activities, and customer preferences to determine the ideal poncho specifications. This insight will guide your product selection and marketing strategies.

2. Define Your Technical Specifications

Establish clear technical specifications for the PVC rain ponchos you intend to source. Consider factors such as:

– Material Thickness: Common options range from 0.10mm to 0.35mm; thicker materials may offer better durability.

– Size Variations: Ensure that the ponchos cater to various body types, with an emphasis on ‘one size fits most’ designs.

– Color Options: Bright colors may enhance visibility, which is particularly important for outdoor activities.

3. Evaluate Potential Suppliers

Before making any commitments, it’s essential to conduct thorough evaluations of potential suppliers. Look for:

– Company Reputation: Check for reviews and testimonials from other B2B buyers.

– Certifications: Ensure suppliers comply with safety standards relevant to your target market, such as the California Proposition 65 warning for hazardous materials.

– Production Capacity: Verify that the supplier can meet your order quantities consistently.

4. Request Product Samples

Always request samples before finalizing your order. This allows you to:

– Assess Quality: Evaluate the durability, waterproofing, and overall quality of the ponchos.

– Test Usability: Consider how easy the ponchos are to put on and take off, as well as their comfort and fit during various activities.

5. Negotiate Pricing and Terms

Once you have identified a reliable supplier and evaluated product samples, it’s time to negotiate terms. Focus on:

– Bulk Discounts: Inquire about pricing for larger orders to optimize your margins.

– Shipping Costs: Understand logistics and any additional fees that may apply, especially for international shipments.

– Payment Terms: Discuss favorable payment terms to maintain cash flow, such as partial payments upfront and the balance upon delivery.

6. Review Compliance and Safety Standards

Ensure that the PVC rain ponchos comply with relevant safety and environmental regulations in your target markets. This is especially important in regions like Europe, where compliance can significantly impact your business’s reputation and legality.

7. Establish a Quality Control Process

Implement a quality control process to monitor the ponchos once they arrive. This should include:

– Inspection Procedures: Set up a checklist for inspecting the ponchos upon delivery to ensure they meet your specifications.

– Feedback Loop: Establish a method for collecting customer feedback post-purchase to continually refine your product offerings.

By following this checklist, you can ensure that your sourcing process for PVC rain ponchos is efficient, compliant, and aligned with market demands, ultimately leading to successful procurement for your business.

Comprehensive Cost and Pricing Analysis for PVC Rain Poncho Sourcing

What Are the Key Cost Components in PVC Rain Poncho Production?

When sourcing PVC rain ponchos, understanding the cost structure is essential for accurate budgeting and pricing strategy. The main cost components include:

-

Materials: The primary material used is PVC, with thickness typically ranging from 0.10mm to 0.35mm. Higher quality PVC offers better durability and waterproofing but comes at a higher cost. Additional materials may include hoods, snaps, and packaging.

-

Labor: Labor costs can vary significantly based on the region of production. Countries with lower labor costs may offer more competitive pricing, but quality control can sometimes be an issue.

-

Manufacturing Overhead: This includes utilities, rent, and equipment costs. Efficient production processes can help minimize overhead, which is critical for maintaining competitive pricing.

-

Tooling: Initial investment in molds and tools for manufacturing can be substantial, especially for custom designs. This cost is often amortized over large production runs.

-

Quality Control (QC): Ensuring that each poncho meets safety and quality standards incurs costs. This is particularly important for international buyers who may require specific certifications.

-

Logistics: Transportation costs can fluctuate based on the distance from the manufacturing facility to the buyer’s location. Import duties and taxes also play a significant role in the total cost.

-

Margin: Suppliers typically add a markup to cover their operational costs and profit. Understanding the supplier’s margin expectations can aid in negotiations.

How Do Price Influencers Affect PVC Rain Poncho Sourcing?

Several factors influence the pricing of PVC rain ponchos, and recognizing these can help buyers make informed decisions:

-

Volume/MOQ (Minimum Order Quantity): Larger orders generally yield lower per-unit costs due to economies of scale. Buyers should assess their needs against potential cost savings.

-

Specifications and Customization: Custom designs, colors, or features can increase costs. Buyers should determine if customization is necessary or if standard options suffice.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO, CE) often come at a premium. Buyers should evaluate the importance of these factors relative to their target market.

-

Supplier Factors: The reliability, reputation, and location of suppliers can influence pricing. Establishing strong relationships with trustworthy suppliers can lead to better terms and pricing.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international shipping. They define responsibilities for costs and risks, impacting the total landed cost of goods.

What Negotiation Strategies Should Buyers Use for PVC Rain Ponchos?

To ensure cost-efficiency and favorable pricing, buyers should employ effective negotiation strategies:

-

Leverage Volume Discounts: When placing larger orders, buyers can negotiate better pricing. It’s beneficial to communicate future order intentions to encourage favorable terms.

-

Request Multiple Quotes: Obtaining quotes from various suppliers can provide a benchmark for negotiations. It’s essential to compare not just price but also quality and service.

-

Discuss Payment Terms: Flexible payment terms can alleviate upfront costs and improve cash flow. Buyers should negotiate terms that align with their financial capabilities.

-

Focus on Total Cost of Ownership (TCO): Consider all costs associated with sourcing, including shipping, customs, and potential returns. A lower upfront price may not always equate to lower overall costs.

What Are the Pricing Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rates can impact the final price. Buyers should factor in potential currency risks when making purchasing decisions.

-

Import Duties and Taxes: Understanding local regulations regarding imports can help avoid unexpected costs. Researching tariff classifications for PVC products is vital.

-

Cultural Considerations: Different regions may have varying expectations regarding pricing and negotiation styles. Being culturally aware can enhance communication and negotiation outcomes.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on supplier agreements, market conditions, and specific buyer requirements. Always conduct thorough research and obtain updated quotes before making purchasing decisions.

Alternatives Analysis: Comparing PVC Rain Poncho With Other Solutions

Exploring Alternatives to PVC Rain Ponchos in B2B Markets

In the B2B landscape, particularly within regions like Africa, South America, the Middle East, and Europe, businesses often seek effective solutions for weather protection. While PVC rain ponchos are popular for their lightweight and waterproof qualities, it’s essential to evaluate alternative options that may better suit specific needs or preferences. This analysis will compare PVC rain ponchos with heavy-duty rain suits and disposable rain ponchos to provide actionable insights for international buyers.

| Comparison Aspect | PVC Rain Poncho | Heavy-Duty Rain Suit | Disposable Rain Poncho |

|---|---|---|---|

| Performance | Good waterproofing, lightweight | Excellent durability, longer wear | Basic protection, short-term use |

| Cost | $10 – $35 | $20 – $50 | $1 – $5 |

| Ease of Implementation | Easy to wear, one-size-fits-most | Requires fitting, may be bulkier | Ready to use, no setup needed |

| Maintenance | Minimal, easy to clean | Requires regular cleaning | Single-use, no maintenance |

| Best Use Case | Sporting events, short hikes | Construction, outdoor work | Festivals, emergency kits |

Detailed Breakdown of Alternatives

Heavy-Duty Rain Suit: Is it Worth the Investment?

Heavy-duty rain suits are designed for environments where durability is paramount. Made from thicker materials, these suits provide superior protection against heavy rain and wind. Their longevity makes them ideal for construction workers or outdoor laborers who face harsh conditions regularly. However, they can be bulkier and may require specific sizing, making them less convenient for casual use. The investment is higher, but the long-term benefits can justify the cost for businesses that require reliable weatherproof solutions.

Disposable Rain Poncho: A Quick and Economical Solution?

Disposable rain ponchos are an economical option for events where temporary protection is needed, such as outdoor festivals or sports events. Priced at just a few dollars, they are lightweight and easy to distribute, making them suitable for large groups. However, their single-use nature means they are not environmentally friendly and provide less protection compared to PVC ponchos or heavy-duty suits. For businesses focused on cost-efficiency and short-term needs, disposable ponchos can be a practical choice, but they may not align with sustainability goals.

Making the Right Choice for Your Business Needs

When choosing between PVC rain ponchos and their alternatives, businesses must consider the specific context in which the product will be used. For light, temporary protection during events, PVC ponchos or disposable options may suffice. Conversely, industries requiring robust, long-lasting solutions should consider heavy-duty rain suits despite the higher initial investment. Ultimately, the decision should factor in performance requirements, cost constraints, and environmental considerations, ensuring that the chosen solution aligns with both operational needs and corporate values.

Essential Technical Properties and Trade Terminology for PVC Rain Poncho

What Are the Key Technical Properties of PVC Rain Ponchos?

When considering the procurement of PVC rain ponchos, understanding their technical properties is crucial. Here are several critical specifications that B2B buyers should evaluate:

-

Material Thickness (mm):

The thickness of the PVC material is typically measured in millimeters (mm). Common thicknesses range from 0.10 mm to 0.35 mm. A thicker poncho offers better durability and waterproofing, which is essential for harsh weather conditions. For instance, a poncho with a thickness of 0.20 mm or more is generally suitable for outdoor activities and emergency situations, ensuring longevity and effective water resistance. -

Welded Seams:

The construction of a poncho often includes welded seams rather than stitched seams. Welded seams provide superior waterproofing as they eliminate needle holes that can allow water to seep through. This property is vital for end-users who need reliable protection from rain, making it an important consideration for B2B buyers looking for quality and performance. -

Size and Fit:

Most PVC rain ponchos are designed to be one-size-fits-all, typically measuring around 50” x 80”. The large size ensures adequate coverage for a variety of body types, which is advantageous for bulk purchasing. Offering a poncho that fits most users can reduce inventory complexity and improve customer satisfaction. -

Hood Design:

An attached hood is a standard feature that enhances the poncho’s utility. The hood should have an adjustable drawstring to ensure a snug fit, preventing rain from entering and providing better visibility. This feature is particularly important for outdoor workers and recreational users who need full protection while maintaining comfort. -

Color Options:

While functionality is crucial, aesthetic considerations also play a role in B2B purchases. Offering ponchos in various colors, such as yellow, green, and blue, can cater to different market preferences. Bright colors can enhance visibility in low-light conditions, which is particularly important for safety in industrial applications. -

Weight:

The weight of the poncho can impact its portability. Lightweight options (around 0.10 mm thickness) are ideal for short-term use or events where carrying extra gear is impractical. Understanding the weight helps buyers consider shipping costs and ease of distribution, especially in international markets.

What Are Common Trade Terms Used in the PVC Rain Poncho Industry?

Familiarizing yourself with industry jargon can facilitate smoother transactions and negotiations. Here are some essential terms:

-

OEM (Original Equipment Manufacturer):

This term refers to companies that produce parts or products that are sold under another brand’s name. In the context of PVC rain ponchos, OEM relationships can offer B2B buyers tailored products that meet specific requirements while benefiting from the manufacturing expertise of established companies. -

MOQ (Minimum Order Quantity):

MOQ indicates the smallest quantity a supplier is willing to sell. Understanding MOQ is crucial for buyers to gauge inventory needs and manage cash flow effectively. For instance, a supplier may require an MOQ of 500 units, which could affect purchasing decisions based on projected demand. -

RFQ (Request for Quotation):

An RFQ is a document issued by buyers to solicit price offers from suppliers. It typically includes specifications, quantities, and delivery requirements. Properly articulating an RFQ can lead to more accurate quotes and better negotiation outcomes, ensuring that buyers receive the best value for their investment. -

Incoterms (International Commercial Terms):

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Key Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify shipping responsibilities and costs, which is essential for B2B buyers engaged in global sourcing. -

Lead Time:

Lead time refers to the time taken from placing an order to its delivery. Understanding lead time is essential for inventory planning and ensuring timely product availability, especially in regions with unpredictable weather patterns where demand for rain ponchos can surge.

By equipping themselves with knowledge of these properties and terms, B2B buyers can make informed decisions that align with their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the PVC Rain Poncho Sector

What Are the Current Market Trends Impacting the PVC Rain Poncho Sector?

The PVC rain poncho market is experiencing significant growth driven by several global factors. Increasing urbanization, rising outdoor activities, and unpredictable weather patterns are making rain protection gear essential for consumers and businesses alike. In regions such as Africa and South America, where sudden downpours can disrupt daily activities, the demand for lightweight, portable rain gear is on the rise. Furthermore, the trend towards minimalism in outdoor gear is fostering interest in multifunctional products like rain ponchos, which can serve as both a protective layer and a compact accessory.

Emerging technologies in the B2B sourcing landscape are also reshaping the market. Digital platforms are facilitating direct connections between manufacturers and international buyers, streamlining procurement processes. These platforms often provide detailed product specifications, user reviews, and pricing comparisons, enabling businesses to make informed purchasing decisions. Additionally, the integration of AI and machine learning in supply chain management is optimizing inventory levels and forecasting demand, which is particularly beneficial for buyers in fluctuating markets.

As buyers from Europe, the Middle East, and Africa increasingly seek competitive pricing and quality, manufacturers are adapting by offering diverse product lines that include various sizes, colors, and thicknesses of PVC. This trend is evidenced by the availability of options like heavyweight and reversible ponchos, which cater to both durability and visibility needs.

How Is Sustainability Influencing B2B Sourcing of PVC Rain Ponchos?

Sustainability is becoming a critical consideration for B2B buyers in the PVC rain poncho sector. The environmental impact of PVC production, particularly regarding its lifecycle and disposal, has raised concerns among consumers and businesses alike. As a result, many companies are prioritizing ethical sourcing and transparent supply chains. This shift is prompting manufacturers to explore alternative materials or processes that reduce environmental footprints, such as using recycled PVC or minimizing harmful additives.

Moreover, buyers are increasingly looking for products that carry ‘green’ certifications, which validate the sustainability of materials used in production. Certifications like OEKO-TEX and REACH compliance ensure that the ponchos meet safety and environmental standards. For international buyers, especially in regions like Europe where stringent regulations are in place, sourcing from manufacturers that demonstrate a commitment to sustainability can enhance brand reputation and customer loyalty.

Incorporating sustainable practices into sourcing strategies not only aligns with global trends but also meets the growing consumer demand for eco-friendly products. As companies embrace sustainability, they can position themselves as leaders in the market, appealing to environmentally conscious consumers and businesses.

How Has the PVC Rain Poncho Market Evolved Over Time?

The evolution of the PVC rain poncho market reflects broader changes in consumer behavior and environmental awareness. Initially perceived as a basic protective garment, rain ponchos have transformed into versatile accessories that cater to various outdoor activities, from camping to sports events. The introduction of lightweight and portable designs has enhanced their appeal, making them a staple in emergency preparedness kits and outdoor gear.

Historically, PVC was favored for its waterproof properties and affordability, but growing environmental concerns have led manufacturers to innovate. Today, the market features a range of products, including biodegradable options and those made from recycled materials, responding to the dual demands of functionality and sustainability. This evolution underscores the importance of adaptability in the B2B landscape, where buyers are increasingly looking for products that align with their values and operational needs.

In summary, understanding market dynamics, embracing sustainability, and recognizing the evolution of product offerings will equip international B2B buyers with the insights needed to navigate the PVC rain poncho sector effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of PVC Rain Poncho

1. How do I choose the right PVC rain poncho for my business needs?

When selecting a PVC rain poncho, consider factors such as material thickness, size, and intended use. Lightweight ponchos (0.10mm) are ideal for short-term use, such as events or festivals, while heavier options (0.35mm) provide more durability for industrial applications. Additionally, assess the poncho’s features, such as attached hoods and snap closures, which enhance functionality. It’s also vital to evaluate color options for branding or visibility in specific environments.

2. What customization options are available for PVC rain ponchos?

Many suppliers offer customization options, including color choices, sizes, and printing capabilities for logos or branding. Customization can help your product stand out in the market. When inquiring with suppliers, ask about minimum order quantities (MOQs) for personalized designs, as these can vary significantly. Ensure you communicate your specific requirements to get the best results.

3. What are the common minimum order quantities (MOQs) for PVC rain ponchos?

MOQs for PVC rain ponchos can vary widely depending on the supplier and the level of customization required. Generally, standard ponchos may have MOQs ranging from 500 to 1,000 units, while customized options might require larger orders. Always confirm with the supplier about their specific MOQ policies, as this can affect your budget and inventory planning.

4. How can I vet suppliers of PVC rain ponchos for reliability?

To vet suppliers, start by reviewing their business credentials, including certifications and industry experience. Request samples to assess product quality and verify their compliance with safety standards, especially regarding materials used. Additionally, check customer reviews and testimonials, and consider conducting site visits if feasible. Establishing a clear communication channel will also help gauge their responsiveness and willingness to collaborate.

5. What payment terms should I expect when sourcing PVC rain ponchos?

Payment terms can vary by supplier and region. Common practices include deposits ranging from 30% to 50% upfront, with the balance due before shipment. Some suppliers may also offer net terms (e.g., net 30 or net 60), allowing you to pay after receiving goods. Always clarify payment options, including accepted methods and currencies, especially when dealing with international transactions to avoid misunderstandings.

6. What are the key quality assurance measures for PVC rain ponchos?

Quality assurance measures should include material testing for durability and waterproofing, as well as inspections during and after production. Request documentation of compliance with relevant safety standards, especially in regions with strict regulations. Implementing a quality control plan that includes pre-production and in-line inspections can help ensure that the final product meets your specifications.

7. How do logistics and shipping impact the sourcing of PVC rain ponchos?

Logistics and shipping are critical to the overall sourcing process. Factors to consider include lead times, shipping methods, and costs associated with international freight. Ensure that the supplier has a reliable logistics partner and can provide options for expedited shipping if necessary. Familiarize yourself with import regulations and tariffs in your country to prevent unexpected delays or costs upon arrival.

8. Are there any environmental concerns associated with PVC rain ponchos?

Yes, PVC (polyvinyl chloride) raises environmental concerns due to its production process and potential for harmful chemicals. Many suppliers are now focusing on sustainable practices, offering eco-friendly alternatives. When sourcing, inquire about the environmental policies of your supplier and the materials used in their products. Consider exploring options that meet certifications for sustainability to align with your corporate social responsibility goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 1 Pvc Rain Poncho Manufacturers & Suppliers List

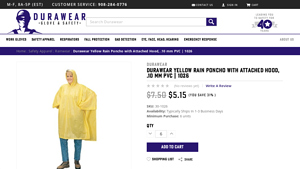

1. Durawear – Yellow Rain Poncho with Attached Hood

Domain: durawear.com

Registered: 1999 (26 years)

Introduction: {“product_name”: “Durawear Yellow Rain Poncho with Attached Hood”, “material”: “.10 mm PVC”, “SKU”: “1026”, “price”: “$5.15”, “original_price”: “$7.50”, “discount”: “31%”, “size”: “52\” x 80\””, “features”: [“Attached hood”, “Side snaps”, “All one piece”], “availability”: “Typically Ships In 1-3 Business Days”, “minimum_purchase”: “6 units”}

Strategic Sourcing Conclusion and Outlook for PVC Rain Poncho

In the dynamic landscape of international trade, strategic sourcing of PVC rain ponchos presents a valuable opportunity for B2B buyers across Africa, South America, the Middle East, and Europe. Understanding the diverse product offerings—from lightweight, budget-friendly options to durable, multi-functional ponchos—enables businesses to cater to a wide range of consumer needs. The emphasis on features such as waterproof materials, attached hoods, and varying sizes further enhances their appeal in various markets, making them essential for outdoor events, emergency preparedness, and everyday use.

The importance of strategic sourcing cannot be overstated. By leveraging supplier relationships, optimizing procurement processes, and focusing on quality assurance, businesses can secure competitive pricing and reliable inventory. This not only mitigates risks associated with supply chain disruptions but also positions companies to respond swiftly to changing market demands.

As we look to the future, international B2B buyers should prioritize partnerships with reputable manufacturers and distributors who understand local market nuances. By doing so, companies can ensure they are well-equipped to meet customer expectations and drive growth. Embrace the potential of PVC rain ponchos in your product lineup, and position your business for success in an evolving marketplace.